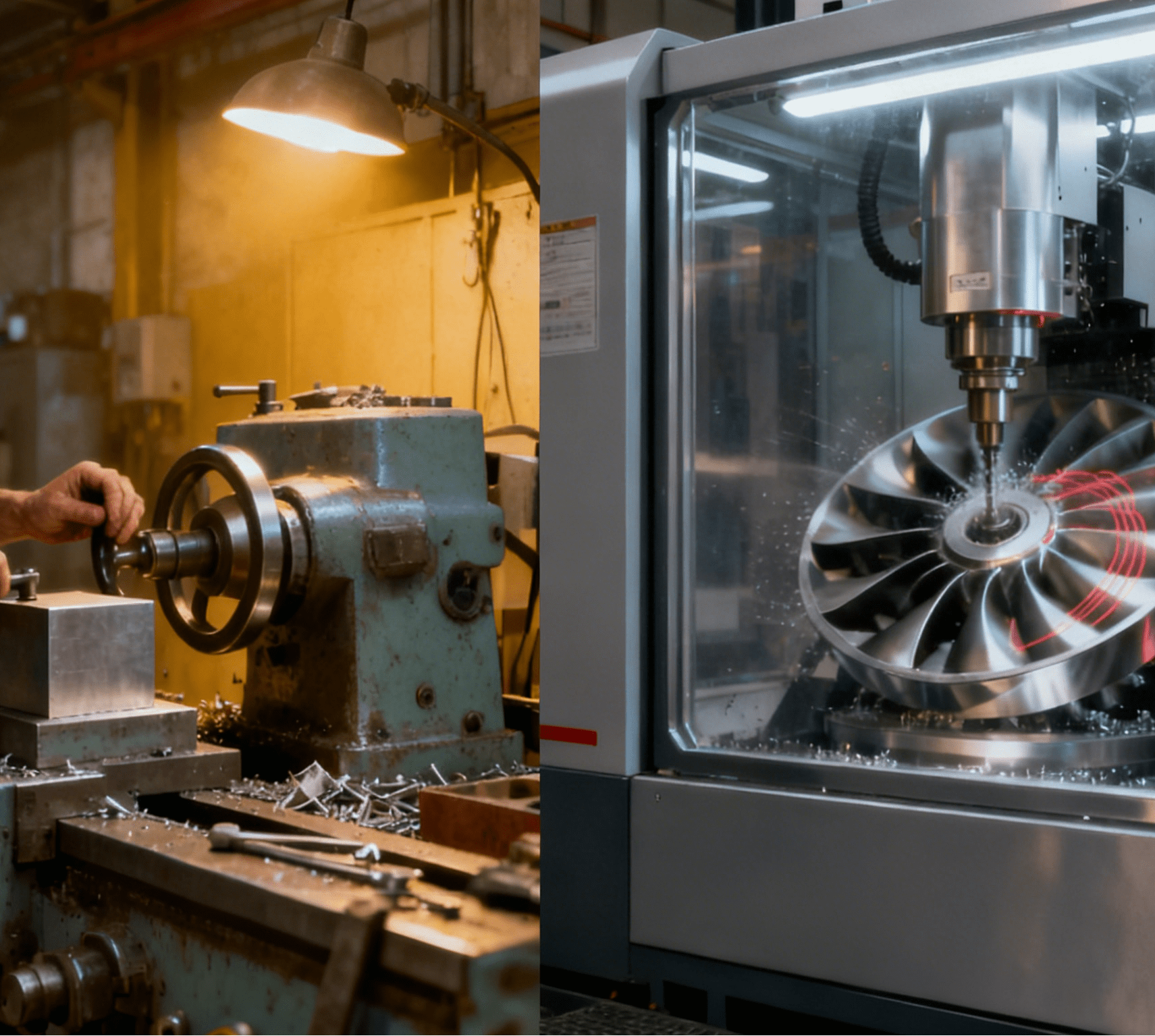

In an era of growing environmental awareness, the precision CNC machining industry is also facing increasingly stringent environmental requirements. This inevitably raises the question: Will these environmental requirements become a stumbling block to the industry’s innovative development?

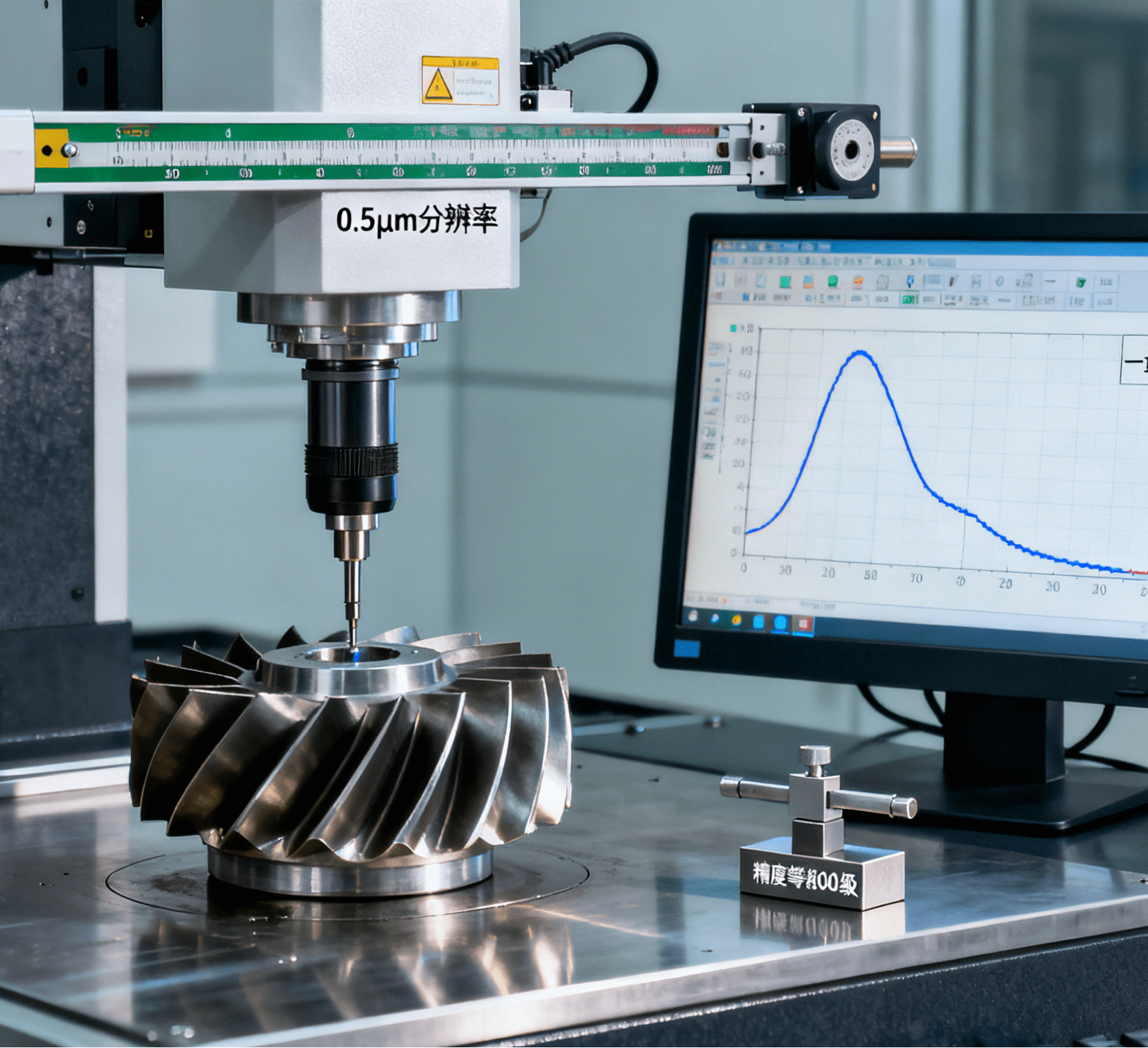

In traditional perception, precision CNC machining is often regarded as a symbol of high-precision and high-efficiency production, with environmental protection not being its primary concern. However, as environmental issues become more prominent, environmental problems arising from the machining process—such as cutting fluid pollution, metal waste disposal, and energy consumption—have gradually gained attention. Environmental requirements force enterprises to properly handle these “by-products” of traditional machining modes. For instance, the use of cutting fluids must comply with strict emission standards, metal waste requires rational recycling and reuse, and the energy efficiency of production equipment is also incorporated into regulatory scope.

Practical Challenges for the Industry Under Environmental Requirements

From certain perspectives, environmental requirements seem to pose challenges to the industry. Some enterprises may need to invest substantial funds in updating equipment and improving processes to meet environmental standards. For example, to reduce the use and pollution of cutting fluids, enterprises may need to introduce advanced dry cutting technology or minimum quantity lubrication technology, which undoubtedly increases their R&D and equipment procurement costs. For some small and medium-sized enterprises, this financial pressure may restrict their investment in other innovative areas, such as the R&D of new tool materials or the optimization of machining processes, thereby affecting the overall pace of industrial innovation to a certain extent.

Moreover, the frequent update and strict implementation of environmental regulations mean enterprises need to spend more energy adapting to and complying with them, which may divert their attention from core business innovation. Enterprises may need to establish dedicated environmental protection departments or positions to handle relevant matters, leading to the reallocation of human and management resources.

Environmental Pressure as a Catalyst for Innovation

However, from a long-term and more macro perspective, environmental requirements are actually an important driving force for the innovative development of the precision CNC machining industry. Firstly, environmental pressure promotes enterprises to develop greener machining technologies. Although technologies like dry cutting and minimum quantity lubrication mentioned earlier require large initial investments, they not only reduce pollution but also improve machining precision and tool life. For example, dry cutting avoids the impact of cutting fluids on the surface quality of workpieces, which is conducive to improving product quality and has unique advantages in the machining of some precision components. Another typical case is the innovative upgrade of Automatic Sealing Ring Feeding and Assembly equipment: to meet environmental requirements of reducing material waste and energy consumption, enterprises have integrated intelligent detection and precise positioning systems into the equipment, realizing automated and high-precision feeding and assembly. This not only minimizes sealing ring waste caused by manual operation errors but also adopts energy-saving drive modules and recyclable material conveying structures, perfectly combining environmental protection goals with production efficiency improvement.

Secondly, environmental requirements drive the innovative application of materials science in the field of CNC machining. To reduce the generation of metal waste, enterprises have begun to explore new materials with better machinability and easier recyclability, or develop material modification technologies to improve material utilization. This has stimulated cooperation and communication between material scientists and CNC machining enterprises, promoting the emergence of interdisciplinary innovative achievements.

Furthermore, in terms of energy utilization, environmental demands have prompted enterprises to carry out energy-saving transformations on machining equipment or adopt new energy-efficient equipment. For example, the R&D of high-efficiency and energy-saving motors and the optimization of machine tool power management systems—these innovations not only reduce enterprises’ energy costs but also align with the global trend of sustainable development, enhancing their social image and market competitiveness.

The Path of Synergistic Development Between Environmental Protection and Innovation

In summary, although environmental requirements in the precision CNC machining industry may bring certain pressures and challenges to enterprises in the short term, in the long run, they are by no means an obstacle to the industry’s innovative development, but rather a powerful driving force. They urge enterprises to break through traditional thinking, actively explore new green, efficient, and sustainable machining modes, and move forward on the path of synergistic development between environmental protection and innovation, laying a solid foundation for the transformation, upgrading, and sustainable development of the entire industry.

What is the work done using automated equipment and machines called?