CNC precision manufacturing refers to a production process that adopts computer numerical control technology to precisely control machining equipment, so as to achieve high-precision and high-consistency product manufacturing. In the modern industrial field, we deeply recognize the importance of this manufacturing method. On the one hand, CNC technology can not only realize the machining of components with complex shapes, but also greatly reduce manual intervention, thereby improving production efficiency. On the other hand, precision manufacturing plays an indispensable role in many key industries, such as aerospace, medical devices and the automotive industry, because these fields have extremely high requirements for product precision and reliability. Through CNC precision manufacturing, we can ensure that every product is manufactured within the strictest tolerance range, which improves the reliability and safety of the entire production line. In addition, after adopting this advanced technology, we can also maintain a competitive edge in the ever-changing market environment, enabling enterprises to remain invincible in the fierce market competition. Therefore, CNC precision manufacturing is not only a technological advancement, but also an important foundation for driving the entire industry towards high quality and high efficiency.

How We Understand the Advantages of Precision Manufacturing

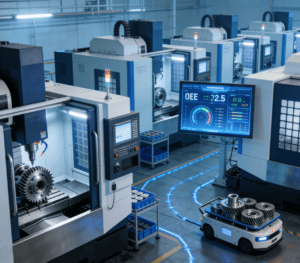

In modern industry, the advantages of precision manufacturing are becoming increasingly prominent, which enables us to be more competitive in the face of fierce market competition. First of all, improving production efficiency is one of the key factors for us to understand the advantages of precision manufacturing. By using advanced CNC technology, enterprises can realize automated production, reduce manual intervention, increase machining speed, and thus significantly shorten the production cycle. Specifically, in the processing of sheet metal materials widely used in automotive, aerospace and other industries, the integration of Sheet automatic loading robots with CNC equipment has achieved full automation of the sheet feeding process — these robots can accurately and continuously transport raw material sheets to the CNC machine tool, avoiding the delay and error caused by manual loading, ensuring the continuity of the machining process and further improving the overall production efficiency. Secondly, reducing production costs is another crucial approach. CNC precision manufacturing can efficiently utilize raw materials and reduce waste; at the same time, by optimizing production processes and workflows, production costs are greatly reduced, which allows us to enter the market with more competitive prices.

In addition, improving product quality and consistency is also an important advantage of precision manufacturing. With the help of CNC technology, we can achieve consistency and precision in mass production while maintaining high standards, which is crucial for meeting customer needs and improving customer satisfaction. Through these advantages, we not only improve the overall operational efficiency, but also lay a solid foundation for future development, thereby enhancing the enterprises’ risk resistance ability in the complex market environment.

Application Cases of CNC Machining in Various Industries

The wide application of CNC machining technology can be seen in multiple industries, which fully demonstrates its importance in improving production efficiency and product quality. For example, in the aerospace field, CNC machining can accurately manufacture complex components, ensuring their operational safety and reliability. Due to the extremely high precision requirements of these parts, the advantages of CNC technology are particularly prominent. In the automotive manufacturing industry, we can observe that CNC machining is widely used in the production of body parts and engine components, which all require high precision and consistency to ensure good vehicle performance and compliance with safety standards. In addition, in the medical device industry, the high-precision feature of CNC technology enables us to produce medical equipment that meets strict hygiene standards and usage requirements. A growing number of enterprises are beginning to use CNC machining to enhance the market competitiveness of their products. Through these cases, it is not difficult for us to find that this technology is not only a production method, but also an important driving force for the development of modern industry. All walks of life are actively adopting CNC precision manufacturing to adapt to the rapidly changing market demand, while achieving a higher level of automation and intelligence.

Future Development Trends: How We Should Address Challenges

Facing the future, the CNC precision manufacturing industry will face a series of challenges, including rapid technological updates, changing market demands and intensified competition. We need to keep up with industry dynamics, adapt to changes in customer needs, and flexibly adjust production strategies to ensure that our products always meet market standards. Informatization and intelligence are the keys to improving production efficiency. We can consider introducing the Internet of Things (IoT) and big data analysis technology to monitor the production process in real time, thereby improving the effectiveness of decision-making. At the same time, the improvement of employees’ skills cannot be ignored. We should regularly conduct professional training for employees to make them familiar with the latest CNC technology and related software, so as to ensure operational accuracy. In addition, sustainable development is also an important direction we need to focus on. By optimizing resource allocation and reducing waste emissions, we can not only reduce production costs, but also enhance the corporate image. Through the above measures, we can better address various challenges in the market and continuously promote the development of CNC precision manufacturing to a higher level.

Robots realize the automated assembly of automotive connectors