The Pain Points of Traditional Machining & CNC’s Core Solutions

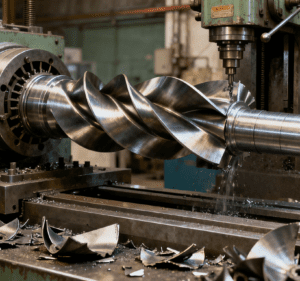

Traditional machining methods often fall short when dealing with complex parts. Complex parts typically feature unique geometric shapes, such as complex curved surfaces, deep holes, and thin-walled structures. These characteristics make it difficult to plan tool paths during machining and easily lead to issues like machining interference and uncontrollable precision. For instance, turbine blades in aero-engines have twisted curved surfaces and extremely high precision requirements. Machining them with traditional machine tools not only results in low efficiency but also a high rejection rate.

CNC machining addresses these challenges through advanced computer control systems and precision machine tool structures. First, in the programming phase, with the help of professional CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software, engineers can accurately plan tool paths based on the 3D model of complex parts. The software can simulate the machining process, identify potential collision and interference issues in advance, and make optimization adjustments. Take machining a part with a complex inner cavity as an example: programmers can use the software to generate spiral tool paths, allowing the tool to smoothly enter the inner cavity and complete cutting. This avoids tool damage or reduced machining quality caused by unreasonable tool paths in traditional machining.

Key Technologies Powering CNC’s Precision in Complex Machining

Multi-axis linkage technology is a key approach for CNC machining to unlock the code of complex part machining. Traditional machine tools generally only support 2-axis or 3-axis linkage, while multi-axis CNC machine tools—such as 5-axis machining centers—can simultaneously control the tool’s movement along five coordinate axes. This ensures that when machining complex curved surfaces, the tool can always maintain the optimal cutting angle with the workpiece surface, thereby improving machining precision and surface quality. For example, when engraving sculpture molds with complex human figures, a 5-axis machining center can, like a skilled artist, accurately shape details such as facial contours and body curves, endowing the mold with extremely high precision and artistic expressiveness.

In addition, tool technology in CNC machining is constantly evolving. Various specialized tools have been developed to meet different machining requirements of complex parts. For example, to machine deep holes, there are dedicated deep-hole drills with excellent chip removal performance and cooling systems, which ensure tool stability and machining precision during deep-hole machining. For machining thin-walled parts, sharp tools with vibration-damping functions are used to reduce vibration during machining and prevent deformation of thin walls.

During the machining process, the real-time monitoring and feedback function of the CNC system is also crucial. Sensors conduct real-time monitoring of parameters such as tool wear, machine tool temperature, and vibration. Once an abnormality is detected, the CNC system immediately adjusts machining parameters—such as reducing cutting speed or adjusting feed rate—to ensure the smooth progress of machining. For example, when tool wear leads to increased cutting force, the system automatically reduces the feed rate, avoiding reduced machining precision or tool breakage caused by excessive tool wear.

Automated Production & Industrial Value of CNC Machining

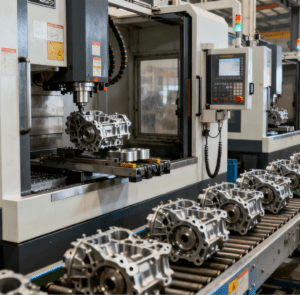

CNC machining also enables automated production, improving production efficiency. By integrating with automated loading/unloading devices and material conveying systems, it can realize mass production of complex parts. For example, in the manufacturing of auto parts, a large number of complex-shaped parts such as transmission housings can be efficiently produced through CNC automated production lines, meeting the mass production needs of the automotive industry. Beyond the automotive sector, CNC machining’s high-precision components also provide core support for medical equipment like Catheter Assembly Machines—CNC-machined precision mechanical structures and core assembly components ensure the assembly machine operates with micron-level accuracy when assembling medical catheters, fully meeting the strict precision requirements of the medical industry.

Relying on multiple advantages—including advanced programming technology, multi-axis linkage capability, specialized tool development, real-time monitoring and feedback, and automated production—CNC machining has successfully unlocked the code to complex part machining. It not only drives the development of numerous industries such as aerospace, automotive manufacturing, and mold machining but also lays a solid foundation for future smart manufacturing. This allows humans to continuously pursue higher precision and more complex processes in the field of mechanical manufacturing, creating more advanced industrial products.