Table of Contents

ToggleAutomatic Hardware Part Feeding and Assembly: Unleashing Efficiency in Modern Manufacturing

Introduction

In the realm of industrial production, hardware parts—ranging from tiny screws and nuts to complex metal brackets and connectors—are the fundamental building blocks across diverse sectors, including automotive, electronics, furniture, and aerospace. Traditional manual and semi-automated methods for hardware part feeding and assembly are fraught with limitations: slow cycle times (averaging 40–60 seconds per assembly), high labor costs (up to 40% of total production expenses), and inconsistent quality due to human error. Automatic hardware part feeding and assembly systems have emerged as a transformative solution, integrating advanced robotics, intelligent control, and precision engineering to revolutionize manufacturing processes.

A prime example is a leading appliance manufacturer that adopted an automated assembly line for refrigerator door hinges. The system increased daily output by 300%, reduced labor requirements by 80%, and improved assembly precision from ±0.5mm to ±0.1mm. As a result, warranty claims related to loose or misaligned components dropped by 75%, demonstrating the profound impact of automation on both productivity and product reliability.

Technical Architecture: A Symphony of Precision and Automation

The effectiveness of automatic hardware part feeding and assembly systems lies in their meticulously designed components, which 协同高效完成物料输送、精准装配与质量管控:

1. Automatic Part Feeding Sub-System

Vibratory Bowl Feeders

Vibratory bowl feeders are the workhorses of hardware part orientation and feeding. These devices use controlled vibrations to move parts along a helical track within a bowl-shaped enclosure. Custom-engineered tracks feature slots, chutes, and ridges that align parts in the desired position as they travel upwards. For instance, in the assembly of computer server racks, vibratory bowls can precisely orient self-tapping screws with their threads facing downwards, enabling seamless pick-up by robotic grippers. Advanced models allow real-time adjustment of vibration frequency and amplitude, optimizing feeding speed for different part geometries.

Belt Conveyor and Sorting Systems

For larger or irregularly shaped hardware components—such as metal plates, washers, or large bolts—belt conveyor systems offer continuous and high-volume feeding. Photoelectric sensors integrated along the conveyor detect part presence and position, while pneumatic or electromagnetic sorting mechanisms separate components based on size, weight, or orientation. In furniture manufacturing, conveyor systems can sort and distribute metal corner brackets to multiple assembly stations simultaneously, streamlining the production of tables and chairs.

Flexible Feeding Solutions

In high-mix, low-volume production environments, flexible feeding systems leverage 3D vision and robotics to handle diverse part types. Randomly placed parts on a flat surface are scanned by high-resolution cameras, which generate digital models and calculate each part’s position and orientation within milliseconds. AI-driven algorithms then direct robotic arms equipped with versatile end-effectors—such as magnetic grippers for ferrous components or vacuum cups for flat parts—to execute precise pick-and-place operations. This flexibility enables rapid changeovers between different product models, reducing setup times by up to 90%.

2. Automated Assembly Unit

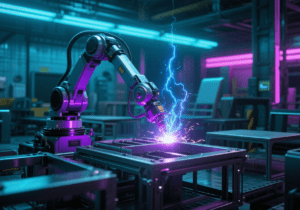

Robotic Assembly Cells

Multi-axis robotic arms, particularly six-axis articulated robots (e.g., FANUC M-20iD or ABB IRB 6700), serve as the core of the assembly process. These robots offer exceptional precision (repeatability of ±0.02mm) and flexibility, capable of executing complex tasks like screw driving, part insertion, and component fastening. In automotive engine assembly, robots equipped with electric torque guns can tighten bolts to exact specifications (e.g., 120 ± 3 N·m), ensuring consistent joint strength and preventing over-tightening or under-tightening.

Intelligent Assembly Tooling

Customized end-effectors and tooling are crucial for hardware assembly. Screw-driving tools feature integrated torque sensors that monitor and adjust tightening force in real-time, ensuring compliance with torque requirements. For press-fit operations, servo presses with force-displacement monitoring can insert pins or bushings with micron-level accuracy. In electronics manufacturing, vacuum grippers with anti-static properties handle delicate metal connectors, preventing damage during handling and placement.

3. Integrated Quality Control

Vision Inspection Systems

High-resolution cameras and advanced image processing algorithms form the backbone of quality control. Vision systems can detect missing parts, misaligned components, or incorrect fastener placement within milliseconds. In the production of consumer electronics, cameras equipped with deep learning algorithms can identify minute defects, such as scratches on metal housings or incorrectly seated screws, with an accuracy rate exceeding 99.8%. Defective units are automatically flagged and removed from the production line.

Force and Torque Monitoring

During fastening operations, force-torque sensors provide real-time feedback on the applied force and torque. These sensors ensure that each fastener meets the required specifications; if a bolt fails to reach the target torque (e.g., a 15% deviation), the system halts assembly, triggers an alert, and logs the data for traceability. This proactive approach minimizes the risk of product failures caused by loose or over-tightened components.

4. Control and Monitoring System

A combination of Programmable Logic Controllers (PLCs) and industrial PCs orchestrates the entire assembly process. PLCs manage real-time operations, including conveyor speeds, robotic movements, and sensor inputs, with sub-millisecond response times. Industrial PCs handle higher-level functions, such as production scheduling, recipe management, and data analytics. IoT connectivity enables remote monitoring of machine performance, allowing manufacturers to track key metrics like Overall Equipment Effectiveness (OEE), predict maintenance needs, and optimize production workflows.

Industry Applications: Transforming Diverse Sectors

Automatic hardware part feeding and assembly systems have become indispensable across multiple industries:

1. Automotive Manufacturing

Chassis and Powertrain Assembly

In automotive production, these systems automate the assembly of thousands of hardware components per vehicle. Robots precisely install bolts, nuts, and brackets on engine blocks, transmissions, and suspension systems, ensuring consistent torque values and component alignment. For example, a single robotic cell can complete the assembly of a car’s rear suspension in under 2 minutes, a task that previously took 10 minutes with manual labor.

2. Consumer Electronics

Smartphone and Laptop Manufacturing

In the electronics industry, automated systems handle the delicate assembly of metal frames, connectors, and screws. Vacuum grippers pick and place tiny components (e.g., SIM card tray latches), while servo-driven screwdrivers tighten micro-screws with extreme precision. This automation reduces the risk of electrostatic discharge damage and improves the overall durability of devices, contributing to higher customer satisfaction.

3. Furniture Production

Metal and Hybrid Furniture Assembly

Furniture manufacturers leverage automatic systems to streamline the assembly of metal frames for chairs, tables, and cabinets. Robots weld metal parts together with consistent quality, while vision systems inspect welds for defects like porosity or uneven bead formation. In a high-volume production scenario, an automated line can assemble 500 metal chair frames per hour, compared to just 100 with manual assembly.

4. Aerospace and Defense

Aircraft Component Assembly

In aerospace, where safety and precision are non-negotiable, automatic systems assemble critical hardware components, such as wing fasteners, engine mounts, and landing gear parts. These machines ensure that each bolt is tightened to exact torque specifications (e.g., 300 ± 5 N·m) and that all components meet strict aerospace standards (e.g., AS9100). Traceability features record every assembly step, enabling comprehensive quality audits and compliance with regulatory requirements.

Technological Frontiers: Shaping the Future of Assembly

1. Artificial Intelligence and Machine Learning

AI and ML algorithms are revolutionizing assembly processes by analyzing vast amounts of production data. These technologies can predict part shortages, optimize feeding parameters based on material variations, and even autonomously adjust assembly sequences in real-time. For example, an ML model can learn from historical torque data to identify patterns indicating tool wear, triggering proactive maintenance and reducing downtime.

2. Collaborative Robotics (Cobots)

Cobots are increasingly integrated into assembly lines to enable safe human-robot collaboration. In tasks requiring dexterity or decision-making, cobots assist human operators by handling heavy lifting, repetitive tasks, or precision operations. For instance, a cobot can hand over pre-assembled hardware kits to an operator, reducing physical strain and increasing overall productivity.

3. Digital Twin Technology

Digital twin models simulate the entire assembly process in a virtual environment, allowing manufacturers to test new product designs, optimize workflows, and predict potential bottlenecks before physical implementation. By creating a digital replica of the assembly system, companies can reduce development time, minimize errors, and enhance overall process efficiency.

Implementation Challenges and Solutions

1. High Initial Investment

The cost of implementing an automated system, including robots, feeders, and software, can exceed $1 million. However, manufacturers can offset this through long-term savings in labor costs, reduced scrap rates, and increased production volumes. Government incentives for automation, leasing options, and pay-per-use models also make adoption more accessible.

2. Complex Integration and Programming

Configuring the system for different products requires specialized skills in robotics, programming, and mechanical engineering. To address this, modern systems offer user-friendly software with pre-built assembly recipes, drag-and-drop interfaces, and intuitive programming tools. Additionally, equipment manufacturers provide comprehensive training programs to upskill operators and maintenance staff.

3. Compatibility with Existing Infrastructure

Integrating new automated systems into existing production lines can be challenging due to space constraints and compatibility issues. Modular and scalable designs, along with standardized communication protocols (e.g., OPC UA), simplify integration, allowing seamless connectivity with other manufacturing equipment and ERP systems.

Conclusion

Automatic hardware part feeding and assembly systems represent a paradigm shift in modern manufacturing, enabling unparalleled precision, speed, and flexibility. As industries continue to prioritize efficiency, quality, and cost reduction, these systems will become essential for maintaining competitiveness. By embracing cutting-edge technologies like AI, cobotics, and digital twins, manufacturers can unlock new levels of productivity and drive innovation, shaping the future of industrial production.

#automatic buckle feeding and assembly #high – speed buckle feeding #automatic buckle feeder