Table of Contents

Toggle4-Axis Robotic Frame Pick-up System: Revolutionizing Precision Material Handling in Manufacturing

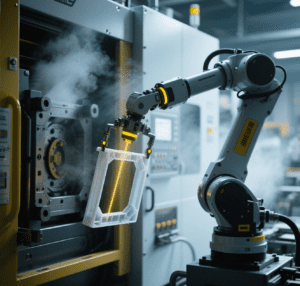

In modern manufacturing, the efficient and precise handling of frames—whether for display panels, circuit boards, or industrial structures—is a make-or-break process. Manual frame picking is slow, error-prone, and risky for workers, while traditional automation often struggles with varying frame sizes, weights, and fragility. Enter the 4-Axis Robotic Frame Pick-up System, a SCARA-based solution engineered to address these challenges with unmatched speed, adaptability, and precision. Designed for industries ranging from consumer electronics to heavy machinery, this system transforms frame handling into a streamlined, reliable, and future-ready operation.

Why 4-Axis for Frame Pick-up? The Perfect Balance of Speed and Control

Four-axis SCARA robots are purpose-built for planar material handling, offering distinct advantages over 6-axis robots or gantry systems for frame-related tasks:

1. High-Speed Planar Motion

With a rigid horizontal arm design and optimized joint mechanics, SCARA robots achieve pick-and-place cycles of up to 150 cycles per minute—2–3x faster than manual workers and 30% faster than 6-axis counterparts for flat-surface operations. For a TV factory picking 55” display frames, this reduces handling time from 8 seconds to just 3 seconds per frame.

2. Sub-Millimeter Precision

A repeatability of ±0.02mm ensures frames are picked and placed with absolute accuracy, even when aligning to tight mechanical tolerances (e.g., inserting a PCB frame into a chassis with 0.1mm clearance). This eliminates misalignments that cause damage or downstream assembly delays.

3. Cost-Effective Flexibility

Compared to 6-axis robots, 4-axis systems cut capital costs by 30–40% and reduce maintenance complexity, thanks to fewer moving parts. Their compact footprint also fits seamlessly into tight production lines, ideal for space-constrained facilities.

Core Technologies: The Brain and Brawn of Smart Frame Handling

The system integrates cutting-edge technologies to solve real-world challenges in frame management:

1. Vision-Guided Localization System

A high-resolution 3D vision camera paired with AI algorithms acts as the robot’s “intelligence,” enabling it to:

- Adapt to Chaotic Environments: Locate frames in stacked or misaligned piles, compensating for positional errors up to 5mm and angular deviations up to 10°.

- Inspect on the Fly: Detect surface defects (scratches, warping, or misdrilled holes) with 99.7% accuracy before picking, preventing faulty frames from entering the production line.

Example: In an automotive plant, the system identifies bent metal frames in a conveyor belt and rejects them, reducing rework costs by 80%.

2. Modular End-of-Arm Tooling (EOAT)

Quick-release grippers and suction systems make the robot versatile enough to handle 100+ frame types, from delicate 0.5mm-thick glass display frames to 20kg steel industrial frames:

- Vacuum Suction for Smooth Surfaces: Safely lifts glass or plastic frames without leaving marks (ideal for OLED/LCD panels).

- Mechanical Grippers with Force Sensing: Clamp metal frames with adjustable pressure (5–50N), preventing deformation during handling.

- Tool Change Time: <5 minutes, allowing seamless switching between frame sizes (from 100mm×100mm PCBs to 2000mm×1000mm industrial racks).

3. Dynamic Path Planning Software

Advanced algorithms optimize the robot’s movement to:

- Avoid Obstacles: Navigate around fixtures, sensors, or human workers in collaborative environments.

- Minimize Cycle Time: Calculate the shortest path between pick and place points, even for complex frame layouts (e.g., staggered trays in logistics).

Transforming Industries: Applications Across the Board

1. Consumer Electronics: Delicate Display Frame Handling

In a smartphone factory assembling OLED display frames (0.3mm-thick glass with 0.05mm alignment tolerances):

- The system uses vacuum grippers and 3D vision to pick frames from a stack of 50, ensuring no scratches or misalignments.

- Places them onto assembly jigs with ±0.03mm accuracy, reducing panel breakage from 5% (manual) to 0.3%.

Result: A leading OEM scales production by 40% while cutting waste costs by $1.2M annually.

2. Industrial Manufacturing: Heavy-Duty Frame Logistics

For steel frame production in construction or machinery plants:

- Robust mechanical grippers handle 30kg steel frames with precision, even in dusty, high-temperature environments.

- Vision system reads QR codes on frames to confirm part numbers and direct them to correct storage locations, eliminating manual sorting errors.

Case Study: A heavy equipment manufacturer reduces frame handling time by 50%, enabling just-in-time production and freeing up 10+ workers for skilled tasks.

3. Logistics & Warehousing: Efficient Frame Palletizing

In e-commerce fulfillment centers managing cardboard or plastic shipping frames:

- The system adapts to varying pallet heights and frame orientations, stacking 100 frames per minute with perfect alignment.

- Integrates with WMS (Warehouse Management System) to optimize pallet load plans in real time, improving storage density by 25%.

4-Axis vs. Traditional Methods: A Clear Performance Edge

| Metric | 4-Axis Robotic System | Manual Handling | 6-Axis Robot | Conventional Gantry |

| Speed (frames/min) | 100–150 | 15–25 | 60–80 | 40–60 |

| Positioning Accuracy | ±0.02mm | ±1mm (variable) | ±0.05mm | ±0.1mm |

| Weight Capacity | 0.1–30kg (modular tools) | 5–15kg (risky) | 5–50kg (overkill for light frames) | 10–100kg (fixed setup) |

| Changeover Time | <10 minutes | 30+ minutes | 20 minutes | 60+ minutes |

| Cost (USD) | $60k–$150k | Labor-intensive | $180k–$300k | $120k–$200k |

The Business Case: Investing in Efficiency and Quality

1. Rapid Return on Investment

- Labor Savings: Replaces 2–4 workers per workstation, saving $50k–$80k annually in labor costs (depending on region).

- Quality Improvements: Reduces frame damage and misalignment defects by 90%, critical for high-value components like OLED panels.

- Scalability: Handles sudden spikes in demand with 24/7 operation and <1% unplanned downtime, thanks to predictive maintenance alerts.

2. Smart Factory Integration

- IoT Connectivity: Feeds real-time data (gripper pressure, cycle times, error logs) to MES systems for process optimization.

- AI-Driven Learning: Continuously refines pick-and-place strategies based on historical data, improving efficiency by 5–10% over time.

The Future of Frame Handling: Where Precision Meets Agility

As manufacturing evolves toward mass customization and higher precision, the 4-Axis Robotic Frame Pick-up System leads the way with innovations like:

- Collaborative Operation: Works safely alongside humans in shared workcells, using 3D safety scanners to avoid collisions.

- Multi-Frame Handling: New gripper designs capable of picking multiple frames at once (e.g., 4 smartphone frames per cycle), boosting throughput further.

- Sustainability Focus: Energy-efficient motors and lightweight arm materials reduce power consumption by 20% compared to older models.

In an industry where every frame counts, this system isn’t just a tool—it’s a transformation. It turns the challenge of handling diverse, delicate, or heavy frames into a competitive advantage, empowering manufacturers to build faster, smarter, and with unmatched precision.

#4Axis Frame Pickup System #SCARA Robot Frame Handling #Automated Precision Material Handling