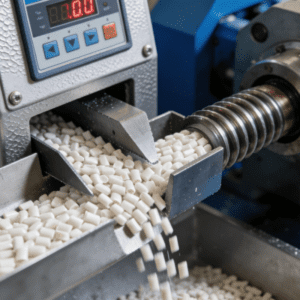

In plastic pelletizing production, chronic issues such as melt pressure fluctuations, unstable output, and uneven pellets occur frequently. These problems not only disrupt continuous production but also directly compromise product quality and profitability. The key to solving these issues lies in the precise control of process parameters. This article focuses on two core aspects—temperature and rotational speed/feeding—and shares a set of actionable optimization methods to help you achieve rapid and stable production.

Temperature Control

Start with Material Characteristics and Lock Down Key Die Head Parameters

The temperature profile must be precisely matched to material properties instead of simply applying generic templates. Taking a commonly used Φ150mm screw as an example, the operating points are as follows:

Material Evaluation First

Clearly distinguish between different material types. For flexible film materials, the temperature of the initial heating zone should be kept low to prevent premature melting that causes feeding slippage. For rigid crushed materials, sufficient heat must be supplied to ensure full plasticization.

Establish a Reasonable Temperature Gradient

Follow the principle of “mild temperature in the front section, sufficient heating in the middle section, and precise control at the die head”. The die head temperature is the key control point for stable discharging. Excessively high temperature will lead to fast discharging and sticky pellets; excessively low temperature will cause a surge in melt pressure and uneven discharging.

Special Strategy for Large-Diameter Screws

Large-diameter screws have high thermal inertia, requiring 20–25 minutes for the temperature to stabilize fully after adjustment. It is recommended to limit the die head temperature adjustment range to a small margin of 10–15℃. Determine the optimal temperature by observing the stability of the melt pressure gauge and the discharging condition.

Coordination of Rotational Speed and Feeding

The Core of Achieving Dynamic Balance

The matching of screw rotational speed and feeding rate is the core to solving output and quality fluctuations. The two parameters must be adjusted in coordination to find an efficient and stable operating point. The following parameter adjustment guidelines apply to equipment with screw diameters ranging from Φ140mm to Φ200mm, serving as a reliable reference for initial setup.

Fine-Tuning Methods and Practical Strategies

Monitor Main Motor Current

During stable operation, the current should be maintained within 85%–95% of the rated value. If the current keeps rising, reduce the feeding rate or check the temperature settings; if the current is low and fluctuating, insufficient feeding may be the cause.

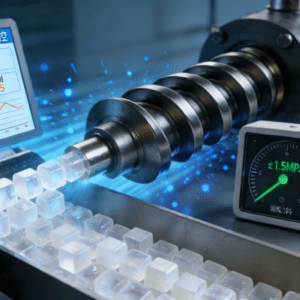

Observe Melt Pressure

The fluctuation range of stable melt pressure should be controlled within ±1.5 MPa. After parameter adjustment, observe the system for at least 15 minutes to allow it to reach a new state of equilibrium.

Adopt the “Segmental Approximation Method”

Especially for long screws, start with relatively low parameters. Adjust only one variable (rotational speed or feeding rate) at a time, with an increment not exceeding 5%, to steadily find the optimal stable range.

By systematically applying the above optimization methods, operators can establish a clearer mindset for process adjustment. This helps shorten commissioning time, reduce production fluctuations and material waste, and provide reliable support for improving product consistency and achieving more stable and efficient production operations.

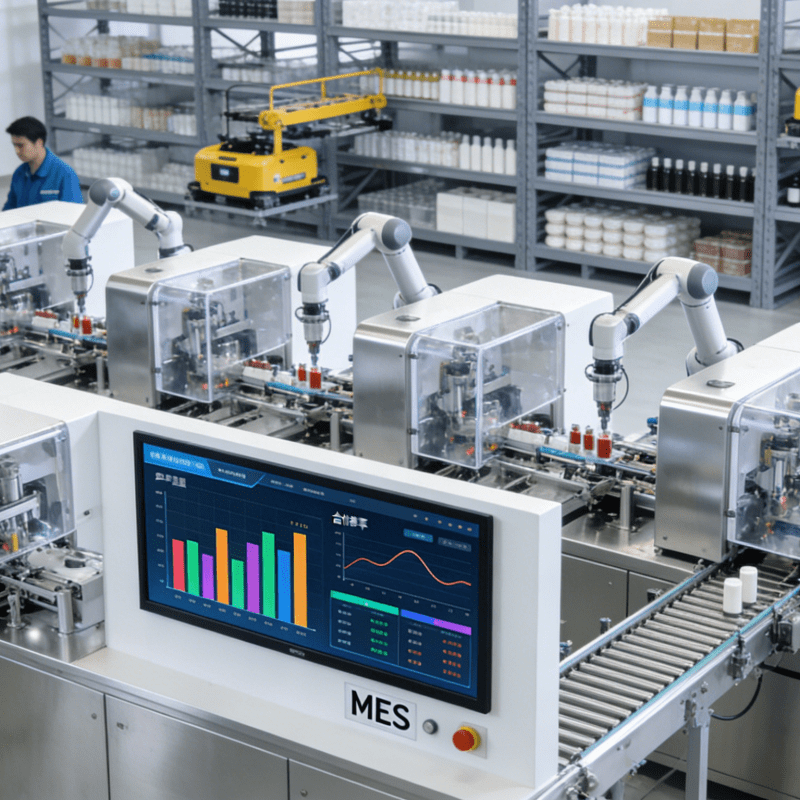

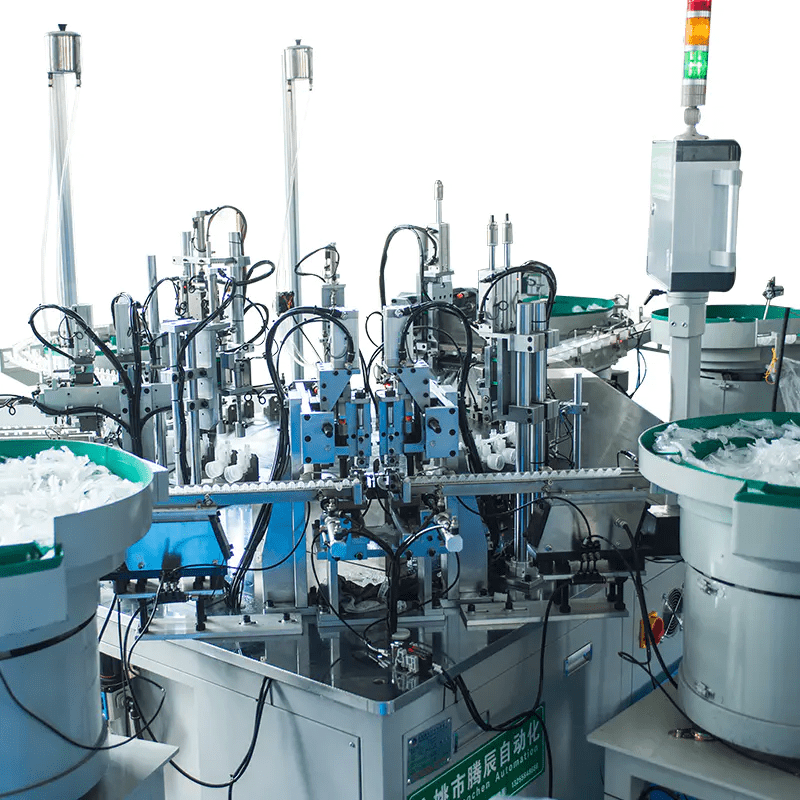

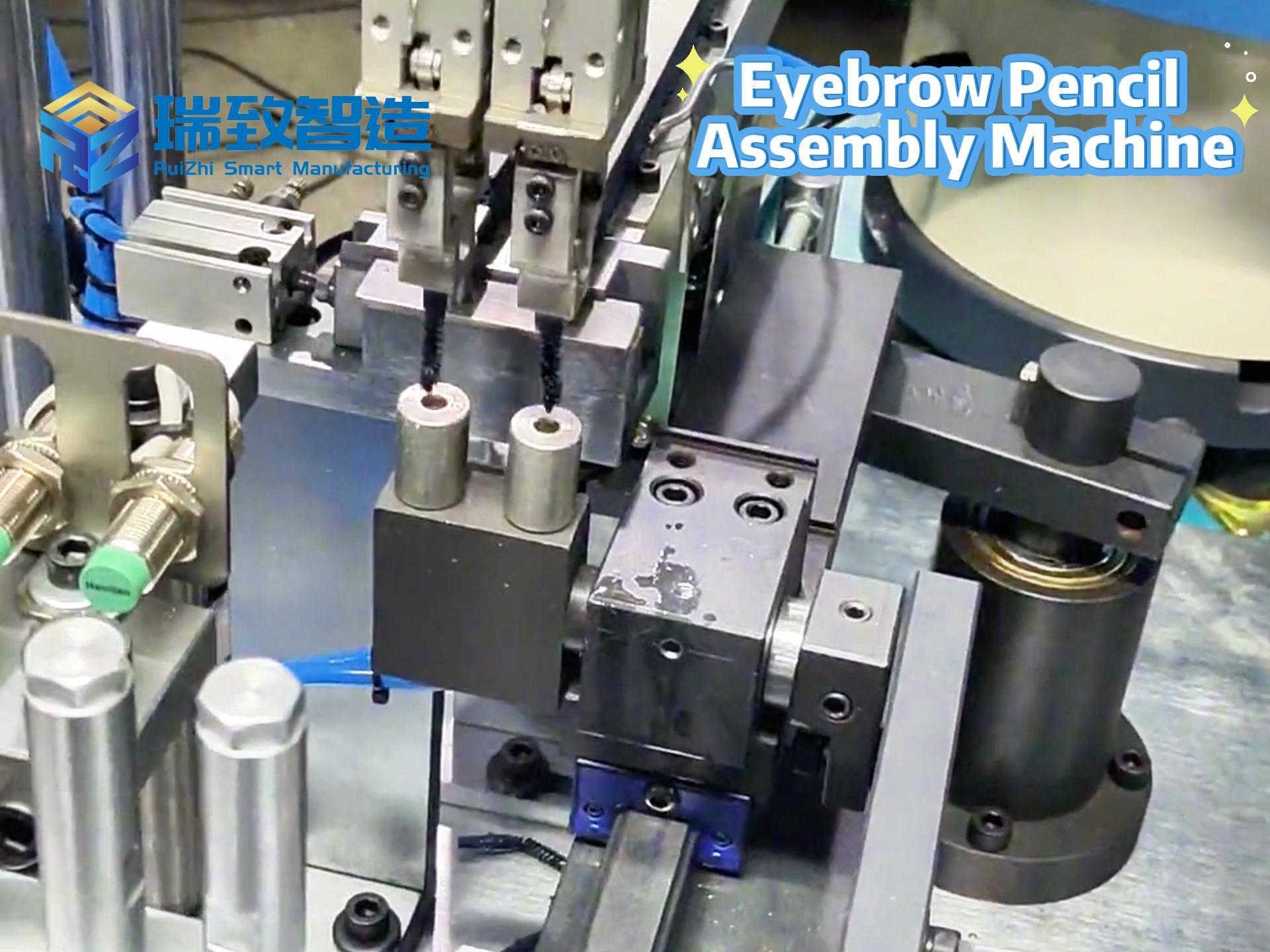

Artificial Intelligence Five-sided Automatic Assembly Machine

Optimization of the five-sided automatic assembly machine by AI