The integration of digital twins and generative artificial intelligence is not only a trend in technological evolution but also a key step for the manufacturing industry to move toward the future. The combination of digital twins and generative artificial intelligence has driven Cyber-Physical Production Systems (CPPS) into a new era of self-learning, self-optimization, and self-adaptation, laying the foundation for the transition of industry from 4.0 to 5.0.

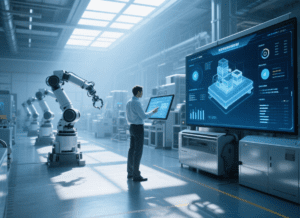

In the era of Industry 4.0, Cyber-Physical Production Systems (CPPS), as the core architecture of smart manufacturing, are reshaping the global manufacturing landscape. CPPS seamlessly integrates computational intelligence with physical processes, building a highly interconnected and dynamically responsive industrial ecosystem that enables real-time communication and collaboration between machines, sensors, and human operators.

Digital Twin: The Core Driver of CPPS

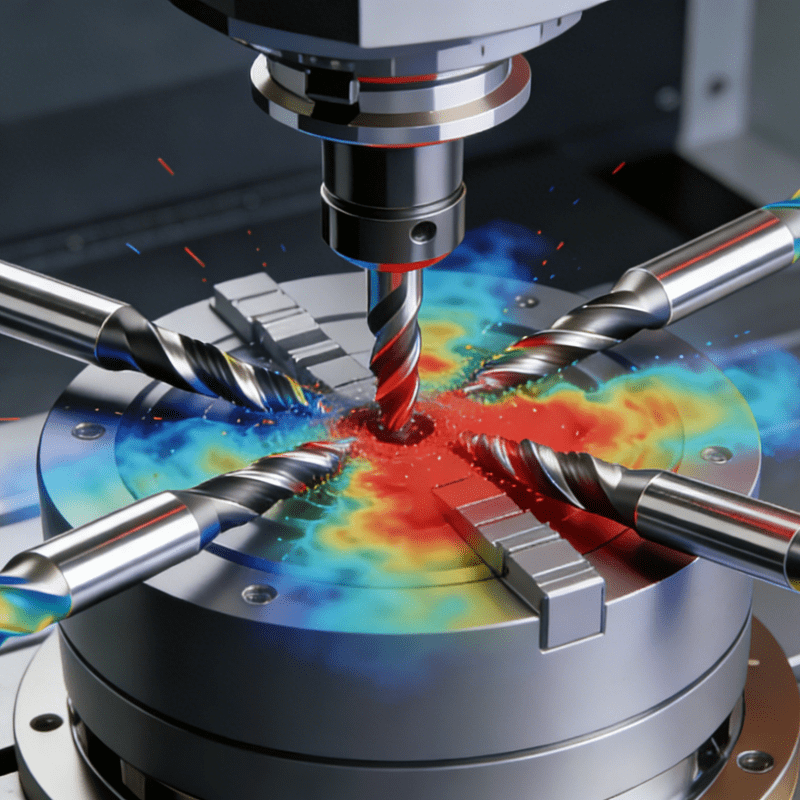

In CPPS, a Digital Twin is a real-time virtual replica of a physical asset that accurately reflects its status, performance, and behavior. With the help of the Industrial Internet of Things (IIoT), edge computing, and sensor networks, digital twins collect and integrate real-time data to mirror and optimize the following systems:

Industrial machinery and equipment

Automated production lines

Warehousing and logistics systems

Digital twins not only enable real-time monitoring of equipment status but also support predictive analysis, process optimization, and decision-making. They have become one of the key technologies to improve operational efficiency and enterprise agility.

Three Core Advantages of Digital Twins in CPPS

Real-time Monitoring and Predictive Insights

Through sensor data and analytical models, digital twins provide the latest digital status of equipment or processes, enabling early fault warnings and predictive maintenance. This significantly reduces unplanned downtime and maintenance costs.

Process Optimization and Resource Efficiency Improvement

Manufacturers can use digital twins to simulate different production scenarios, identify bottlenecks, optimize workflows, and restructure resource allocation, thereby maximizing production efficiency and optimizing resource utilization.

Intelligent Decision-making and Risk Minimization

By previewing process changes and adjustments in a virtual environment, managers can make more forward-looking data-driven decisions while avoiding high trial-and-error costs and potential risks in real operations.

Generative AI: The Intelligent Engine Activating Digital Twins

Generative AI (GenAI) injects true “intelligence” into digital twins. By learning from large-scale historical data and operational patterns, GenAI can not only simulate complex scenarios and generate realistic data but also achieve autonomous reasoning, continuous learning, and real-time response.

How GenAI Empowers Digital Twins:

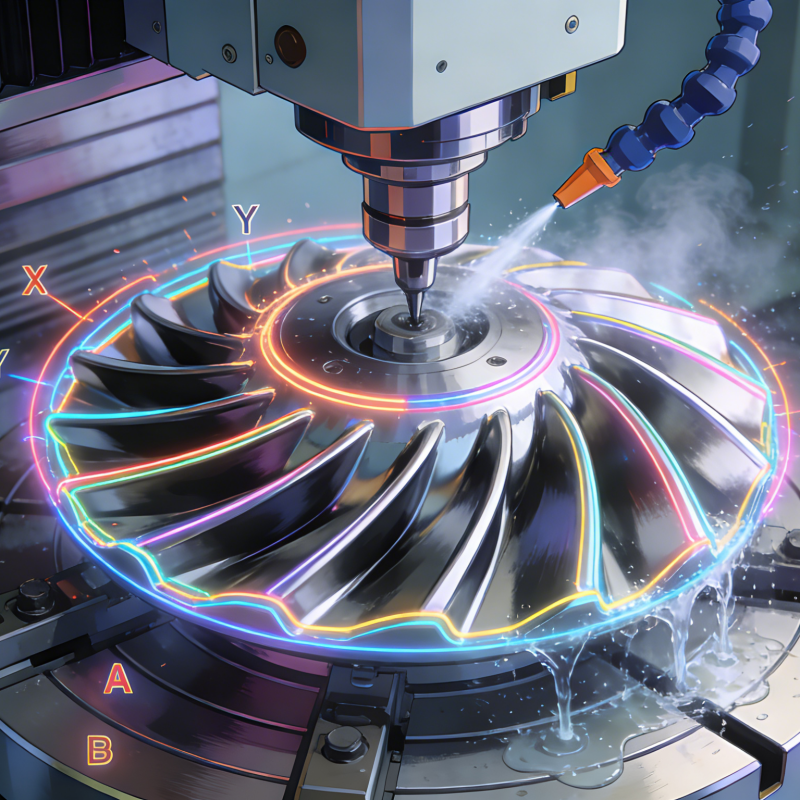

Intelligent Modeling and Predictive Capabilities: GenAI uses deep learning models to generate potential operational scenarios that have not yet occurred and proposes optimal solutions, driving digital twins from passive monitoring to active intervention.

Real-time Adaptation and Automatic Decision-making: The system can automatically analyze data trends and respond intelligently to emergencies, such as adjusting production parameters or optimizing energy consumption strategies.

Synthetic Data Generation and AI Training: Through high-fidelity synthetic data, GenAI provides scalable and repeatable datasets for machine learning models, reducing reliance on expensive physical experiments and accelerating algorithm iteration and innovation.

Digital Twin + GenAI: Opening a New Era of Smart Manufacturing

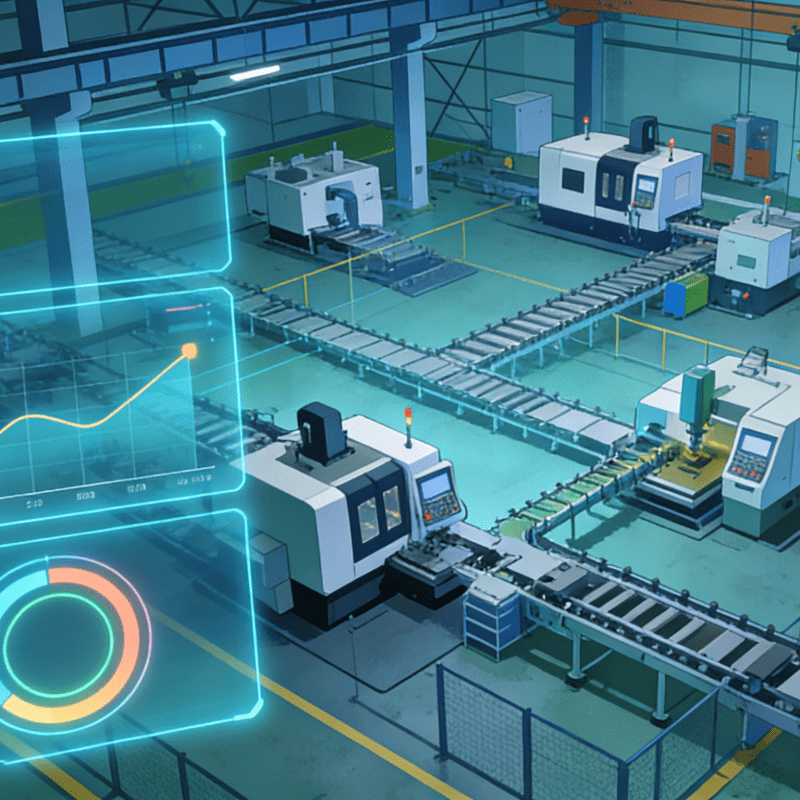

The combination of digital twins and generative AI has driven CPPS into a new era of self-learning, self-optimization, and self-adaptation, laying the foundation for the transition from Industry 4.0 to Industry 5.0. The transformative effects of this integration are reflected in the following key aspects:

Autonomous Optimization and Intelligent Collaboration

AI-driven digital twins can analyze real-time and historical data, automatically identify process bottlenecks, and propose improvement suggestions. This reduces manual intervention and enhances production intelligence.

Next-generation Predictive Maintenance

Through multi-scenario fault simulations generated by GenAI, manufacturers can formulate maintenance plans in advance, avoid unplanned production shutdowns, and extend equipment lifecycle and overall productivity.

Highly Flexible Adaptive Manufacturing

Intelligent twin systems adjust strategies in real-time based on changes in external demands or internal parameters, enabling on-demand production and personalized manufacturing to quickly respond to market changes.

Scalable Synthetic Data Generation

GenAI generates high-quality synthetic data for model training, effectively solving problems such as insufficient industrial data and data privacy issues, and accelerating the deployment and implementation of AI in all aspects of manufacturing.

Toward Industry 5.0: Why Enterprises Must Embrace This Revolution?

As Industry 5.0 approaches, manufacturing will focus more on human-machine collaboration, green sustainability, and extreme efficiency. To stay ahead in future industrial competition, enterprises must actively deploy next-generation technologies including digital twins and generative AI.

Key advantages enterprises will gain include:

Greater agility in manufacturing processes

Cost control and automated operations based on predictive analytics

More sustainable and resource-efficient production models

Deeper customer personalization and service extension

Conclusion

The integration of digital twins and generative AI is not only a trend in technological evolution but also a key step for the manufacturing industry to move toward the future. Enterprises willing to take the lead and embrace change will gain an edge in efficiency, innovation, and sustainability, becoming true leaders in the era of Industry 5.0.

Introduce the Development Trends of Bathroom Shower Head Assembling Machines

What is the working principle of a bathroom shower head assembling machine?