Embodied Intelligence Challenge & Open TeleDex Launch: Ushering in “Triple Any” Teleoperation Era

Since the development of embodied intelligence, enabling robots to accurately replicate human dexterous movements has always been a key challenge in pushing the boundaries of technology. As a “neural bridge” connecting humans and robots, teleoperation systems have become a critical component for humanoid robots to replicate skills. To create a more efficient, responsive, and user-friendly teleoperation system, Lingxinskill has innovatively launched the Open TeleDex modular robotic teleoperation system, ushering in a new era of “Triple Any” for embodied intelligent teleoperation.

Evolution of Teleoperation Systems: From Space-Crossing Control to Time-Crossing Data Collection

In the early days of teleoperation systems, their core value lay in directly operating robots beyond spatial limitations, transmitting the experience and wisdom of various experts to robots in real time without loss—enabling operations in dangerous, remote, or inaccessible environments. With the in-depth development of embodied intelligence, the integration of technologies such as deep learning has shifted the focus of robot development toward skill learning and internalization. Teleoperation systems have thus evolved from a space-crossing intuitive function to a time-crossing tool: they collect data for the learning and training of embodied intelligence, endowing it with real operational data from the physical world and laying a critical foundation for the widespread application of humanoid robots in the future.

Limitations of Current Teleoperation Solutions: Compatibility, Latency, and Rigidity

As teleoperation solutions have flourished, their limitations have become increasingly prominent. Poor device compatibility is the primary pain point: enterprises and research institutions are often locked into specific hardware ecosystems, where data collection devices can only be adapted to particular operating equipment, forming closed technical silos through deep binding. Upgrading devices or experimenting with new robot platforms requires replacing the entire system, which incurs high integration costs. Second, operational latency and asynchrony severely impact precision and user experience. High latency creates a “sense of disconnect” when operators observe robot movements, leading to “over-compensation” of actions that contaminates collected data. Finally, rigid system architectures struggle to adapt to the rapid iteration of robot hardware and diverse application needs today.

Open TeleDex: Addressing Industry Pain Points with “Triple Any” Open Architecture

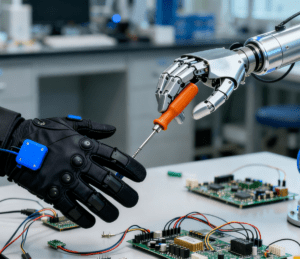

To address the current challenges in the embodied intelligence industry, Lingxinskill has innovatively launched the Open TeleDex modular robotic teleoperation system. It builds an open teleoperation architecture supporting “Triple Any”—Any Equipment, Any Arm, and Any Hand—comprehensively reshaping the entire process of teleoperation systems from architecture to user experience. It provides an integrated “control-data-collaboration” solution for high-precision remote operations, offering efficient technical support for fields such as remote work, robot training, medical assistance, and precision assembly.Notably, in the precision manufacturing of sanitary ware, Open TeleDex has shown strong practical value in collaboration with flush button assembly machines—equipment that demands ultra-fine operations like aligning button shells with internal springs, attaching waterproof gaskets, and tightening micro-screws. Leveraging its “Any Arm” and “Any Hand” compatibility, the system can connect with mainstream collaborative robotic arms (e.g., Universal Robots) and Lingxinskill’s Linker Hand L10 dexterous hands to remotely control the assembly machine’s auxiliary operations: operators use Linker TG teleoperation gloves to simulate finger movements, and the system transmits these actions to the robotic hand with sub-100-millisecond latency, ensuring the flush button components are assembled with a precision error of less than 0.1 mm. Meanwhile, Open TeleDex synchronously collects the assembly process data (such as torque force and component alignment parameters) to optimize the flush button assembly machine’s workflow, realizing a closed loop of “remote control + data-driven optimization” for precision manufacturing.

Composition & “Triple Any” Details of Open TeleDex Modular System

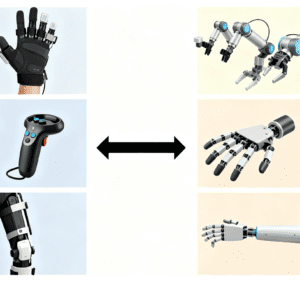

The Open TeleDex modular robotic teleoperation system comprises high-precision master-side force-feedback gloves, high-degree-of-freedom slave-side dexterous hands, high-performance collaborative robotic arms, and ultra-low-latency real-time communication middleware, and adopts a hardware-agnostic architecture. Its revolutionary “Triple Any” features are reflected in the following:

“Any Equipment”: Seamless Integration of Diverse Master-Side Control Terminals

Any Equipment: It natively supports Lingxinskill’s Linker TG teleoperation gloves and Linker TA teleoperation arms, while seamlessly integrating other control terminals such as VR devices and wearable exoskeletons for master-side input.

“Any Arm” & “Any Hand”: Flexible Adaptation to Mainstream Robotic Hardware

Any Arm: It seamlessly enables the operation of any robotic arm and humanoid robot upper body, including Lingxinskill’s Linker Arm and Linker Humanoid robots, as well as mainstream market robotic arms (e.g., from Reeman, Slamtec, and Universal Robots) and humanoid robots (e.g., from Unitree).Any Hand: It supports precise actions such as grasping and manipulation by any dexterous hand in Lingxinskill’s product line, including the Linker Hand L10, O6, and L20.

Hardware Flexibility: Realizing Plug-and-Play & Free Combination of Workstations

This means operators can freely combine data collection devices with robotic arms or humanoid robot upper bodies (based on Lingxinskill’s dexterous hands) to form teleoperation workstations, truly achieving “plug-and-play” and “free combination” of hardware devices.

Core Technical Pillars: Low Latency, Adaptive Mapping, and Hardware Agnosticism

This disruptive experience stems from two core technical pillars of the Open TeleDex modular robotic teleoperation system. First, a deeply optimized real-time data stream protocol drastically reduces the time cost of data collection, transmission, and parsing, stably controlling end-to-end latency at the sub-100-millisecond level. This ensures precise synchronization of movements between operators and robots, nearly eliminating the sense of lag. Second, an innovative adaptive motion mapping algorithm autonomously and intelligently identifies kinematic parameters, automatically completing precise mapping from human joint space to robot joint space. This eliminates tedious calibration processes and significantly shortens system deployment time. Additionally, the hardware-agnostic architecture endows Open TeleDex with broad flexibility and future adaptability, enabling rapid compatibility with emerging hardware devices in the future.

Future Outlook: Teleoperation as a Core Gateway for Embodied Intelligence

In the future, teleoperation systems will serve as the core gateway for the “sympathetic nervous system” and “brain enhancement” of embodied intelligence, acting as the data frontline for embodied intelligence to execute autonomous tasks. They will acquire more realistic and responsive physical world operation data at the execution end while prioritizing better user experiences for operators. Lingxinskill firmly believes that an open, compatible, and efficient teleoperation ecosystem will greatly accelerate the integration of embodied intelligence into real scenarios across industries and daily life, ultimately driving the arrival of the entire embodied intelligence era.