Shareholder Meeting Approval: $1 Trillion Compensation and AI-Robotics Vision

On November 8th, it was reported that during Tesla’s annual shareholder meeting this Thursday (local time), Elon Musk stated that Tesla may have to build “a giant chip factory” to meet the demand for its artificial intelligence (AI) and robotics technologies.

On the same day, shareholders approved his $1 trillion compensation package over the next decade, endorsing his vision of transforming the electric vehicle manufacturer into a leader in AI and robotics.

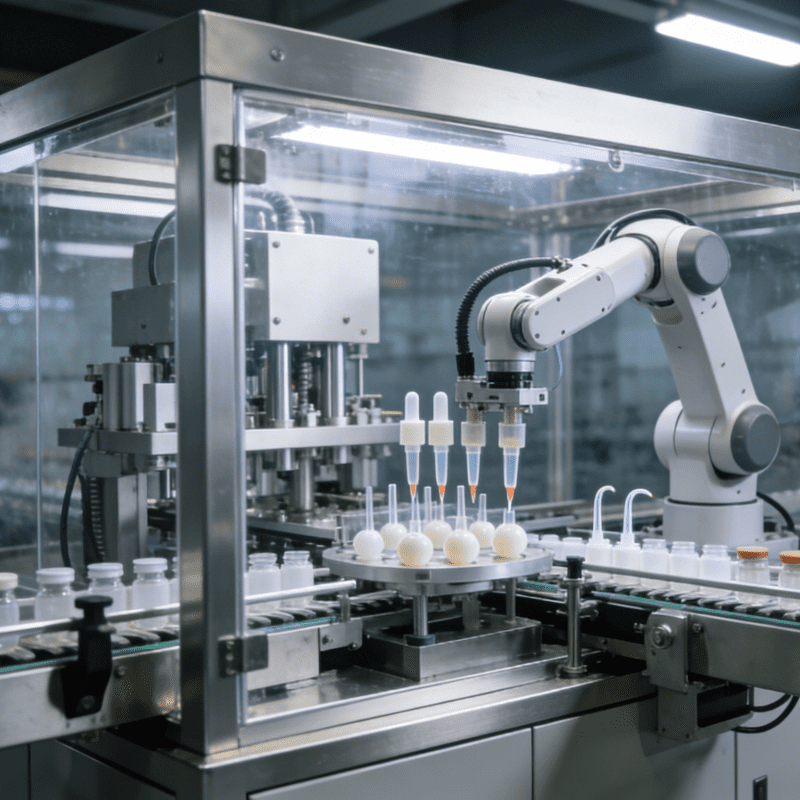

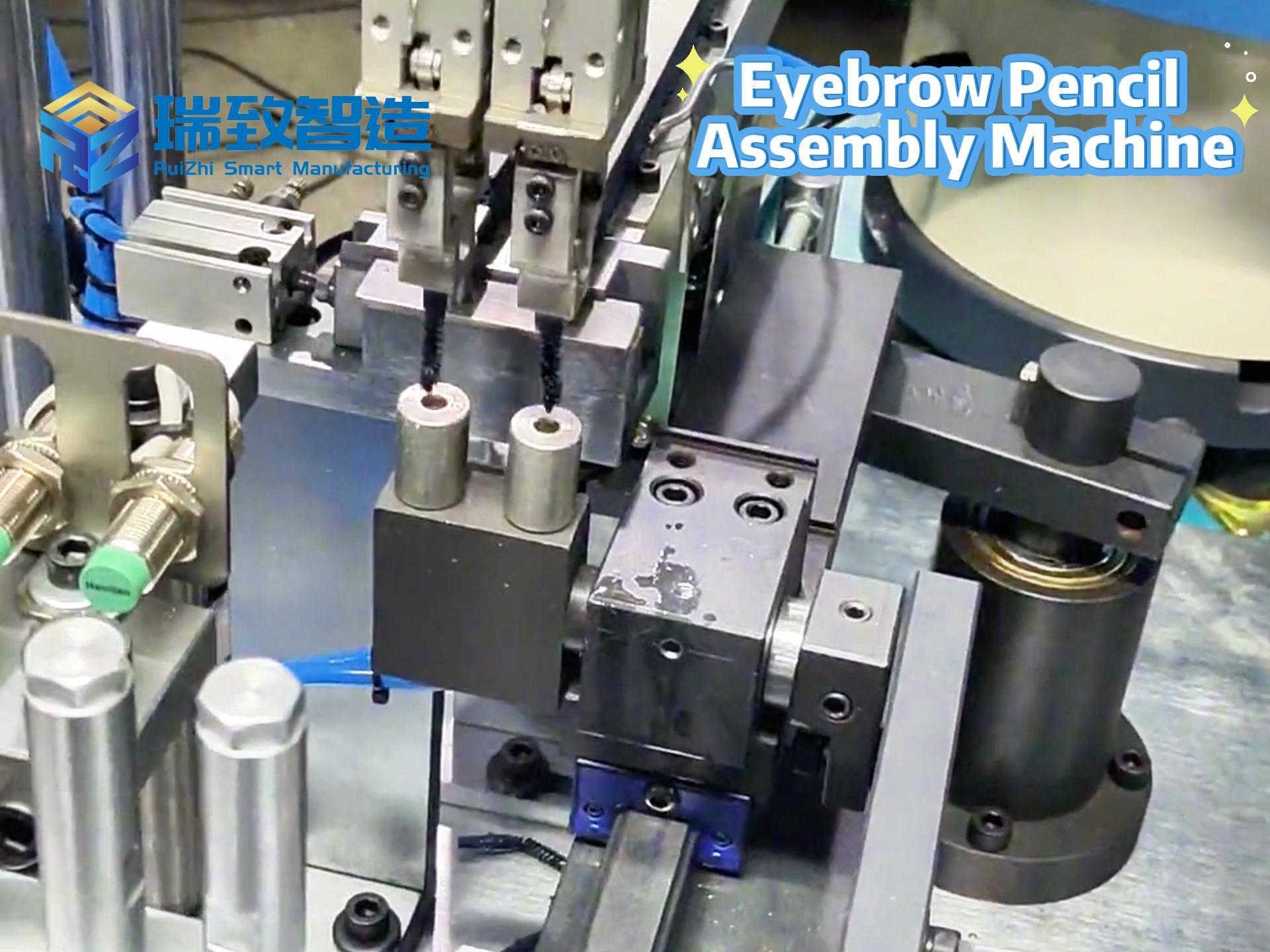

Musk said, “With AI and robotics, you can actually grow the global economy by a factor of 10, maybe even 100, with no obvious limits”—and this will require a massive number of high-performance chips to support not only autonomous driving and humanoid robots but also high-precision medical automation equipment like syringe automatic assembly equipment, which relies on advanced chips to ensure ultra-high assembly accuracy and stable production efficiency.

Existing Chip Cooperation: AI5/AI6 Production Ties with TSMC and Samsung

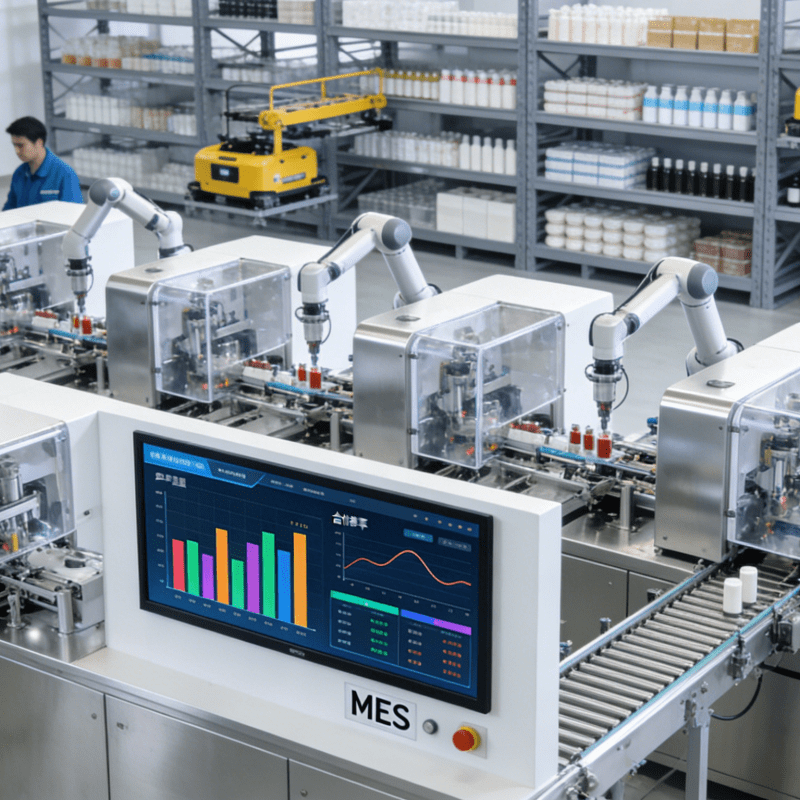

Currently, Tesla is designing its fifth-generation AI chip, AI5, to power its autonomous driving technology. The manufacturing of the AI5 chip is planned to be jointly undertaken by TSMC and Samsung. Small-scale production will start next year, while large-scale supply will not be available until 2027.

Notably, Tesla signed a semiconductor foundry contract with Samsung in July this year, valued at up to 22 trillion won (approximately 107.6 billion yuan).

The focus of this cooperation is to produce “AI6” chips for Tesla, which will be widely used in Tesla’s next-generation Full Self-Driving (FSD) systems, robots, and data centers, among other areas.

Super Wafer Fab Plan: Addressing Capacity Gaps with 1 Million Monthly Wafers Goal

Musk said, “Even when projecting based on the best capacity of our suppliers, the demand still cannot be met. So I think we may need to build a Tesla Terafab, which is similar to a Gigafab but on a larger scale.”

“I can’t think of any other way to achieve the chip output we need, so I believe we may have to build a giant chip factory—it’s something that must be done,” Musk declared.

He also stated that the wafer fab will produce at least 100,000 wafers per month initially, and eventually scale up to 1 million wafers per month, adding that “cooperation with Intel is possible.”

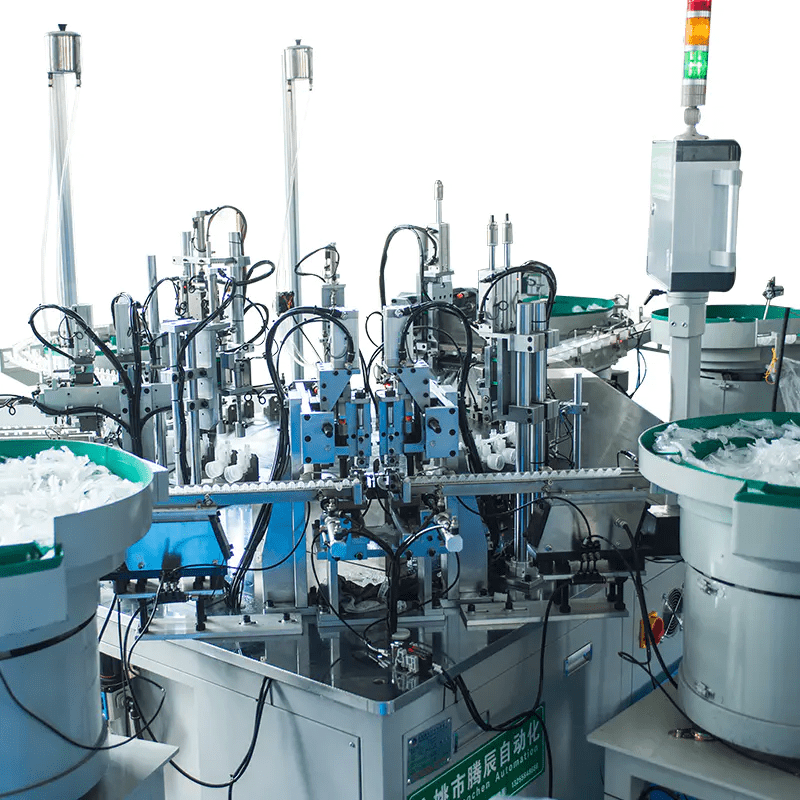

What is the work done using automated equipment and machines called?