In the field of automotive safety testing, crash test dummies stand as “expensive testers” with a unit price ranging from €100,000 to €250,000, while each physical vehicle crash test costs hundreds of thousands of euros. Although these tests are a mandatory step before vehicles enter mass production, the industry has been constantly exploring more efficient and less resource-intensive alternatives — and crash simulators have emerged as a key solution. They eliminate the need to destroy real vehicles, simulating collision scenarios by accelerating test sleds, but face a core challenge: How to dissipate the enormous kinetic energy generated by high-speed impacts to protect valuable testing equipment?

A study by Hochschule Konstanz (University of Applied Sciences) in Germany offers an answer: The integration of high-performance industrial dampers not only builds a “protective barrier” for crash simulators but also enhances test repeatability and cost-effectiveness, making them indispensable “invisible guardians” in safety testing.

The “Impact Dilemma” of Crash Simulators: From Design to Protection

The crash simulator developed by the team at the Laboratory for Measurement Technology and Sensors at Hochschule Konstanz features a simple yet precise design: An electric actuator accelerates a 400 kg test sled to a speed of 3.3 m/s over a few meters, after which the sled detaches and rushes toward its endpoint. During this process, the kinetic energy generated by the accelerated mass reaches 2,178 Nm, enough to cause severe damage to equipment and laboratory structures.

“We must find a reliable braking solution that not only absorbs impact energy but also ensures the repeatability of test data,” notes project leader Prof. Klaus Durst. The team turned to industrial dampers: These devices can convert violent impacts into smooth deceleration through controlled energy absorption, perfectly matching the simulator’s needs.

From “Adaptation” to “Upgrading”: The Logic Behind Damper Selection

The team initially chose two MAGNUM MA4575M dampers from ACE, installed on either side of the sled’s endpoint. This adjustable damper, with an M45x1.5 thread and 75 mm stroke, is an industry benchmark capable of basic protection. However, to achieve higher safety redundancy, the team upgraded the system: A crossbeam was added to the center of the test setup, integrating the largest model in the series, the MA64150M. With an M64x2 thread and 150 mm stroke, it can absorb up to 6,120 Nm of energy per stroke — nearly three times the actual requirement — and handle extreme scenarios where test masses may increase to 80,000 kg in the future.

“The hardened guide bearing and built-in fixed stop design ensure stable and precise energy absorption,” explains project member Sandro Folisi. This stability directly guarantees consistent deceleration curves of the sled in each test, laying the foundation for data reliability.

MAGNUM Series’ “Technological Breakthrough”: Smaller Size, Greater Energy

ACE’s MAGNUM series dampers stand out due to their unique technical design: A combination of wear-resistant guide bearings, hardened piston rings, pot-shaped pressure sleeves, large-diameter pistons, and a new membrane accumulator enables them to absorb 50% more energy than previous models of the same size, while expanding the effective mass range by 200%.

For users, this means “small size, big capability”: They can handle more complex impact scenarios without requiring additional installation space. Additionally, the bidirectional adjustable design allows adjustment from both sides, and continuous threading with universal accessories enables installation at any angle, greatly enhancing design flexibility. Most importantly, the improved energy absorption efficiency reduces the cost per Nm by 30% compared to previous models, achieving a balance between “high performance” and “low cost.”

Beyond Protection: Dampers Reshaping the Future of Safety Testing

Today, this crash simulator integrated with MAGNUM dampers has provided a wealth of critical data for automotive safety system development. It proves that dampers are not just “protective devices” but core components that enhance testing efficiency — indirectly reducing R&D costs by minimizing equipment wear and improving test repeatability.

In the future, as technologies like autonomous driving and new energy vehicles advance, crash tests will face more complex scenarios (e.g., battery collisions, multi-vehicle interactive impacts), demanding higher energy absorption capabilities. Advances in damper technology may bring the vision of “no physical vehicle crash tests” closer to reality. As Prof. Durst puts it: “In safety testing, every precisely absorbed impact energy accumulates confidence in protecting lives on the road.”

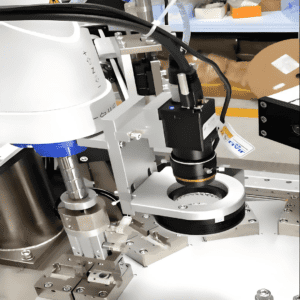

Video of damper assembly machine

Advantages of damper assembly machine