Airtightness is a decisive factor for perfume sprayers, as leaks directly ruin product quality and user experience. Traditional production relies on separate assembly and detection equipment, leading to low efficiency, high error rates, and increased labor costs. Ruizhi Intelligent Manufacturing’s integrated perfume sprayer assembly machine with airtightness detection integrates assembly, testing, and sorting into one, solving industry pain points for perfume & cosmetic factories with high precision and efficiency.

Streamline Production Processes

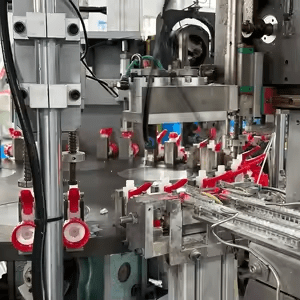

The machine adopts a one-piece integrated structure, combining automatic feeding, nozzle-pump assembly, rubber bulb fitting, airtightness detection, and defective product sorting in a single line. Compared with split-type equipment, it eliminates material transfer links, reducing production time by 30% and avoiding secondary contamination. Equipped with a centralized control system, operators can monitor all processes in real time, realizing unmanned operation from feeding to finished products, with a stable hourly output of 4,500-6,000 pieces.

Guard Cosmetic-Grade Quality

Targeting perfume sprayers’ airtightness requirements, the machine is equipped with high-precision differential pressure detection technology, with a leak detection accuracy of ±0.001MPa. It automatically inflates and detects each sprayer after assembly, instantly identifying products with air leakage and sorting them out. The detection data is traceable and storable, meeting GMP and cosmetic industry quality management standards. This ensures the qualified rate of finished products reaches 99.7%+, far exceeding manual and traditional detection methods.

Fit Diverse Production Needs

As a non-standard automation expert, Ruizhi optimizes the machine for diverse perfume sprayer specs (diameters 8-28mm, materials including aluminum, plastic, and borosilicate glass). Modular fixtures and adjustable detection parameters support quick product changeover in 10 minutes, adapting to small-batch, multi-spec production. Made of 304 stainless steel, the machine is corrosion-resistant, easy to clean, and suitable for cosmetic-grade clean workshops. Ruizhi provides one-stop services from customized debugging to after-sales maintenance, ensuring long-term stable operation.

Ruizhi Intelligent Manufacturing’s integrated machine combines assembly efficiency and airtightness detection precision, helping perfume & cosmetic factories reduce labor costs by over 85% and improve production stability. It has become a preferred solution for enterprises pursuing high-quality, efficient, and standardized perfume sprayer production.