The cosmetic industry’s demand for eyelash brushes is increasingly diversified, with spiral, straight, and mini styles emerging one after another. Traditional standard assembly machines are limited by fixed processes, leading to low efficiency, high labor costs, and difficulty adapting to frequent style changes. Ruizhi Intelligent Manufacturing targets these pain points, providing customized non-standard eyelash brush assembly machines to help factories achieve efficient production upgrades.

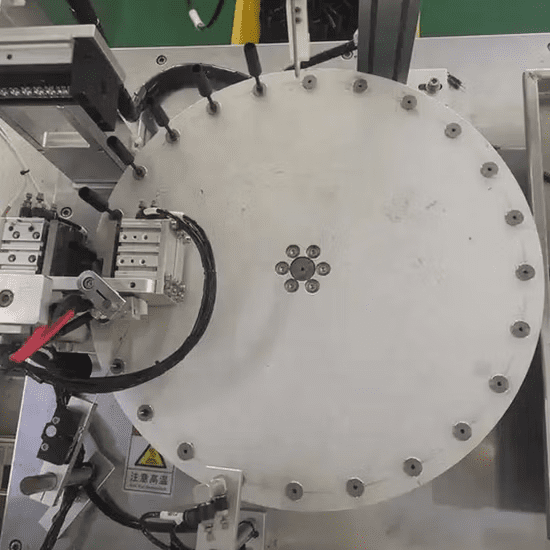

Quick-Change Modular Design: Cut Batch Change Downtime

Ruizhi’s non-standard solutions adopt a quick-change modular structure, addressing the core issue of long downtime in standard equipment during batch changes. Equipped with customized quick-change fixtures, operators can switch between different eyelash brush styles in just 4 minutes, without professional debugging. This design reduces batch change time by over 85% compared to traditional equipment, enabling factories to flexibly respond to small-batch, multi-variety orders and significantly improving overall production efficiency.

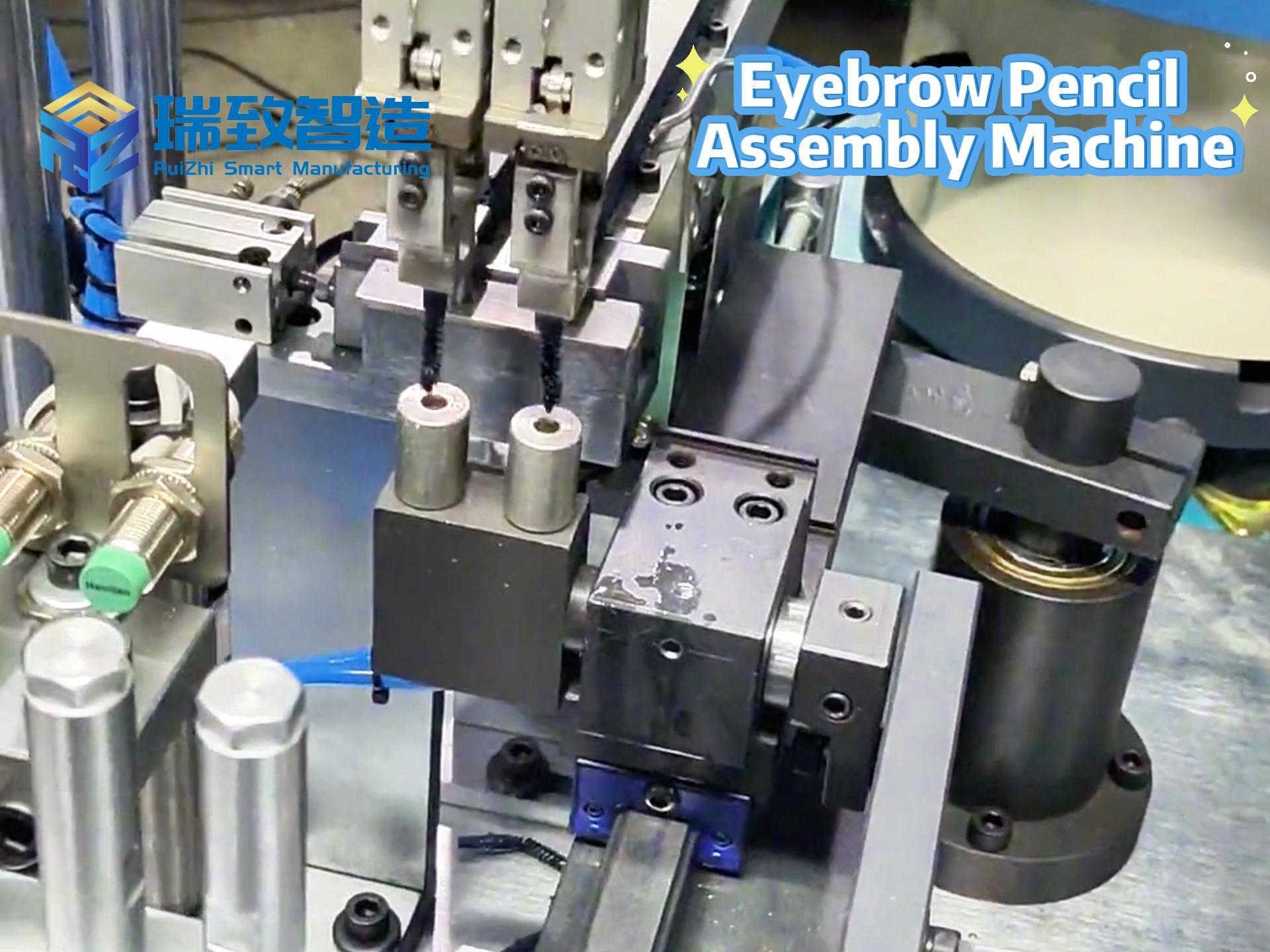

Intelligent Integrated Control: Reduce Labor & Defect Rates

Intelligence is the key to efficiency improvement. Ruizhi integrates PLC systems, AI visual inspection, and servo positioning into the assembly machine, realizing automatic bristle planting, handle assembly, and quality inspection. The AI system detects bristle alignment and density in real time, with a positioning accuracy of ±0.01mm, reducing the defect rate to below 0.7%. One machine can replace 8-10 manual workers, cutting labor costs by 60% while ensuring consistent product quality.

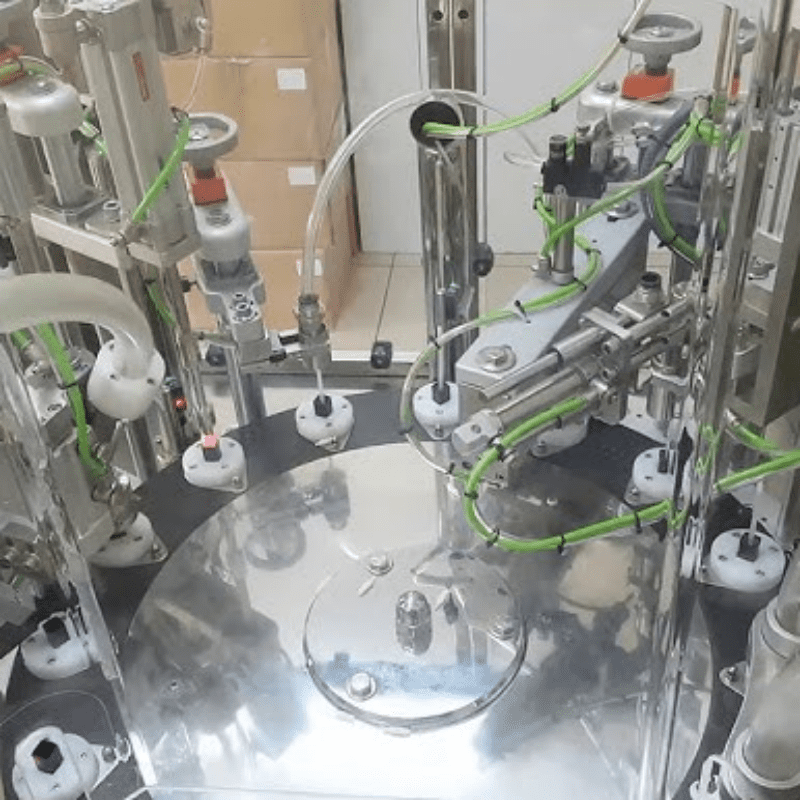

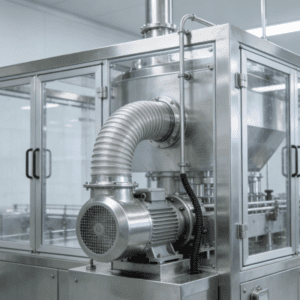

GMP-Compliant Customization: Align with Industrial Norms

Ruizhi’s non-standard machines are designed in line with cosmetic industry GMP standards, using 316L stainless steel and food-grade components to avoid contamination. The closed structure and integrated dust removal system maintain a clean production environment. Energy-saving motors and low-noise operation further reduce operational costs. Customizable assembly stations also support special processes like anti-shedding bristle treatment, fully matching factories’ personalized production needs.

Ruizhi Intelligent Manufacturing’s non-standard eyelash brush assembly machines focus on efficiency improvement and customization. By solving traditional production bottlenecks, they help cosmetic factories gain a competitive edge in the fast-paced market with efficient, precise, and compliant production capabilities.