Sealing rings, as “invisible guardians” of industrial products, play a decisive role in preventing fluid leakage, dust intrusion, and pressure loss. Whether in a car engine’s oil circuit, a household washing machine’s water pump, or a hydraulic valve in construction machinery, the reliability of sealing ring assembly directly determines the product’s service life and safety. However, traditional manual sealing ring feeding and assembly has long been plagued by low efficiency, poor consistency, and high defect rates—becoming a bottleneck for manufacturing enterprises pursuing high-quality and large-scale production. Against this backdrop, the Automatic Sealing Ring Feeding and Assembly System has emerged as a core solution to break through this bottleneck, integrating precision machinery, machine vision, and intelligent control to reshape the standard of sealing assembly.

The “Pain Points” of Traditional Manual Assembly: Why Automation Is Imperative

Before the popularization of automatic systems, sealing ring assembly mostly relied on manual operations, and its limitations were particularly prominent in industries with high-volume production and strict quality requirements:

Low efficiency and high labor costs: A skilled worker can only complete 30-50 sealing ring assembly tasks per hour, and long-term repetitive operations easily lead to fatigue, further reducing efficiency. For enterprises with an annual output of 1 million sets of products, a dedicated assembly team of 10-15 people is often required, and labor costs account for more than 15% of the total production cost.

Poor assembly precision and high defect rates: Sealing rings (especially those with an inner diameter of less than 5mm or made of soft materials like silicone) are prone to deformation, misalignment, or even damage during manual picking and pressing. The assembly coaxiality error often exceeds 0.2mm, and the defect rate caused by sealing failure (such as oil leakage or water seepage) is as high as 8-12%. In the automotive industry, a single sealing failure in the engine can lead to a recall loss of millions of yuan.

Poor consistency and difficulty in traceability: Manual operations are highly dependent on the worker’s experience—some workers may press the sealing ring too hard (causing material fatigue) while others may press it too lightly (leading to insufficient fitting). Moreover, there is no way to record the assembly parameters (such as pressing force and time) of each product, making it impossible to trace the cause of quality problems.

Technical Decoding: The Core Composition of Automatic Sealing Ring Feeding and Assembly System

A mature automatic sealing ring feeding and assembly system is a “collaborative system” composed of five core modules, each undertaking a key link from material supply to final inspection:

- Intelligent Feeding Module: “Orderly Arrangement” of Tiny Sealing Rings

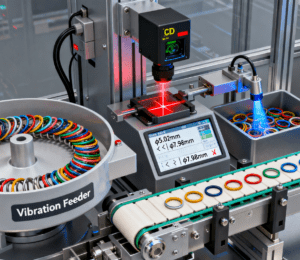

The feeding module is the “starting point” of the system, mainly solving the problem of “disorderly to orderly” sorting of sealing rings. It usually adopts a vibration disk + visual sorting mechanism:

The vibration disk uses adjustable frequency (20-50Hz) electromagnetic vibration to drive the sealing rings to move along the spiral track. The track’s inner wall is designed with a special baffle to screen out deformed or reversed sealing rings (for example, for sealing rings with a concave-convex structure, only those with the correct orientation can pass through the notch).

For special-shaped sealing rings (such as rectangular or D-shaped) or those made of ultra-soft materials (such as fluororubber), a vacuum adsorption + visual positioning auxiliary device is added. The high-resolution industrial camera (12-20 million pixels) identifies the shape and orientation of the sealing rings in real time, and the vacuum suction cup adjusts the angle to ensure that each sealing ring enters the conveying track in a unified posture.

- Precision Conveying Module: Stable Transportation Without Damage

The conveying module connects the feeding and assembly links, and its core requirement is “stable and non-destructive”. It usually uses a synchronous belt conveyor + linear guide rail structure:

The conveyor belt is made of food-grade polyurethane material (with a friction coefficient of 0.3-0.5) to avoid scratching the surface of the sealing ring; the conveying speed is synchronized with the assembly rhythm (adjustable between 0.5-2m/min) to ensure that the sealing ring arrives at the assembly station exactly when needed.

For ultra-small sealing rings (inner diameter <3mm), a micro-pneumatic conveying pipeline is used instead of a conveyor belt. Compressed air (pressure controlled at 0.1-0.2MPa) pushes the sealing ring to the assembly station along the PTFE pipeline, avoiding collision and deformation during transportation.

- Flexible Assembly Module: “Gentle and Accurate” Press-Fitting

The assembly module is the “core execution unit” of the system, and its precision directly determines the assembly quality. It mainly relies on 4-axis/6-axis collaborative robot + force control sensor:

The robot’s repeated positioning accuracy reaches ±0.01mm, which can accurately align the sealing ring with the product’s assembly groove. The end effector is a custom-made soft suction cup (made of silicone with a hardness of 30-50 Shore A) that can firmly grasp the sealing ring without causing indentation.

The force control sensor (measurement range 0-500N, precision ±0.1N) is installed between the robot and the suction cup. During the press-fitting process, it monitors the pressing force in real time: when the force reaches the preset threshold (usually 5-20N, adjusted according to the sealing ring material), the robot stops pressing to avoid over-compression; if the force is lower than the threshold, the system alarms (indicating possible misalignment of the sealing ring).

- Online Detection Module: “Zero Defect” Quality Gate

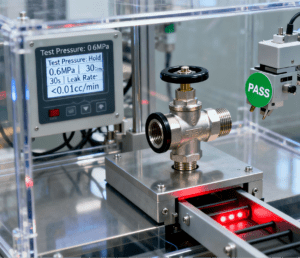

The detection module is the “last line of defense” for quality control, integrating visual inspection + pressure testing:

After assembly, the visual system takes 2-3 photos of the sealing ring from different angles to detect whether there are defects such as misalignment (coaxiality error >0.05mm is judged as defective), deformation, or missing installation. The detection accuracy can reach 99.9%.

For products with high sealing requirements (such as hydraulic cylinders), a micro-pressure testing device is added. The system inflates the sealed cavity (pressure 0.1-0.5MPa) and maintains it for 5-10 seconds; if the pressure drop exceeds 0.005MPa, it is judged as a sealing failure, and the defective product is automatically pushed to the rejection area.

- Intelligent Control Module: The “Brain” of the System

The control module is composed of a PLC (Programmable Logic Controller) and a human-machine interface (HMI), which realizes the coordinated operation of all modules:

The PLC stores 100+ sets of assembly parameters (such as feeding frequency, robot movement path, and pressing force threshold) for different types of sealing rings. When switching products, workers only need to call the corresponding parameter group on the HMI, and the system completes the adjustment within 1-2 minutes.

The HMI displays real-time data such as daily output, qualified rate, and equipment operating status, and supports data export to the MES (Manufacturing Execution System). Managers can trace the assembly parameters of each product (such as pressing force curve and detection results) through the product serial number.

Application Map: From Automotive to Medical, Empowering Multiple Industries

The automatic sealing ring feeding and assembly system has strong adaptability and has been widely used in industries with strict sealing requirements:

- Automotive Industry: Ensuring the Reliability of Key Components

In automotive engine and transmission assembly lines, the system is used to assemble oil seals (such as crankshaft oil seals) and O-rings (such as fuel pipe seals). Taking a joint venture automobile factory as an example, after adopting the system, the assembly efficiency of engine oil seals increased from 40 pieces/hour (manual) to 200 pieces/hour, the defect rate dropped from 10% to 0.5%, and annual labor cost savings exceeded 800,000 yuan.

- Household Appliance Industry: Improving the Consistency of Daily Products

In the production of washing machines and air conditioners, the system is used to assemble water seals (for washing machine inner tubs) and foam seals (for air conditioner casings). A leading home appliance enterprise reported that the system reduced the assembly time of washing machine water seals by 60%, and the complaint rate caused by water leakage dropped by 90%.

- Hydraulic Pneumatic Industry: Meeting High-Precision Sealing Requirements

In the production of hydraulic cylinders and pneumatic valves, the system’s force control and pressure testing functions are particularly critical. A hydraulic component manufacturer in Jiangsu used the system to assemble fluororubber sealing rings, and the sealing failure rate of its products dropped from 5% to 0.1%, winning orders from overseas construction machinery giants.

- Medical Device Industry: Complying with Sterile and Traceable Standards

In the production of infusion pumps and hemodialysis machines, the system uses sterile materials (such as 316L stainless steel for the conveyor belt) and supports Class 100,000 clean room environments. The system records the assembly parameters of each medical device, which meets the requirements of the National Medical Products Administration (NMPA) for product traceability.

Challenges and Future Trends: Towards More Intelligent and Flexible Development

Although the automatic sealing ring feeding and assembly system has achieved remarkable results, it still faces some challenges in practical applications:

Adaptability to special sealing rings: For ultra-thin sealing rings (thickness <0.1mm) or those with complex structures (such as multi-lip seals), the current system’s feeding and grabbing stability needs to be improved.

High initial investment: A set of medium-sized automatic systems costs 300,000-800,000 yuan, which is a heavy burden for small and medium-sized enterprises (SMEs).

In response to these challenges, the future development of the system will focus on three directions:

AI-driven intelligent optimization: Integrate AI vision algorithms to enable the system to automatically identify and adapt to different types of sealing rings (without manual parameter setting), and predict possible failures (such as vibration disk wear) through data analysis.

Modular and low-cost design: Split the system into independent modules (feeding, assembly, detection) so that SMEs can purchase modules on demand, reducing the initial investment by 30-50%.

Green and energy-saving upgrading: Use low-power servo motors (energy consumption reduced by 20%) and recyclable materials for the vibration disk and conveyor belt, in line with the global “carbon neutrality” trend.

Conclusion: From “Manual Fitting” to “Intelligent Assembly”

The automatic sealing ring feeding and assembly system is not just a “replacement of manual labor” but a key carrier for manufacturing enterprises to achieve “precision, consistency, and traceability”. It solves the long-standing quality and efficiency problems in sealing assembly and provides strong support for industries to move towards high-end manufacturing. With the continuous integration of technologies such as AI and flexible robotics, this system will become more intelligent and universal, helping more enterprises break through production bottlenecks and enhance their core competitiveness in the global market.