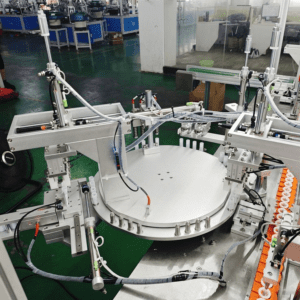

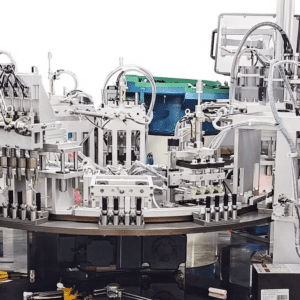

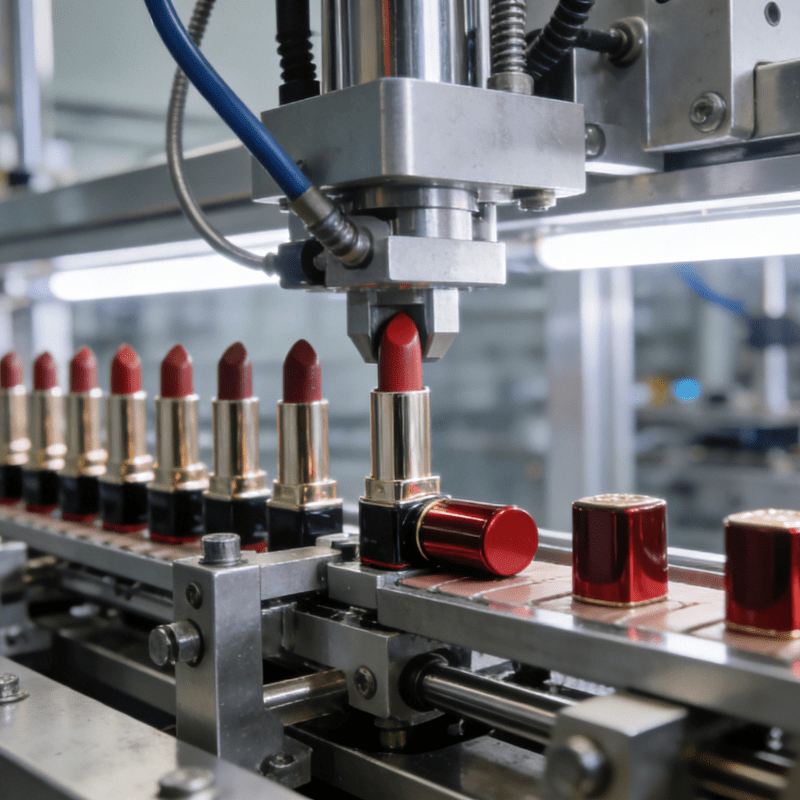

For cosmetic factories, especially small and medium-sized ones, balancing production costs and product quality is a core challenge in lipstick assembly. Standard equipment is either expensive or unable to adapt to diverse lipstick styles, while manual assembly is inefficient and prone to defects. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing launches the Cost-Effective Non-Standard Lipstick Assembly Machine, integrating high cost performance, customized design and stable operation to help factories reduce costs without compromising quality.

Lower Initial Investment & Operation Costs

Ruizhi’s Cost-Effective Non-Standard Lipstick Assembly Machine adopts a rational structural design to control manufacturing costs while ensuring performance. Compared with other non-standard equipment on the market, our machine reduces initial investment by 20%-30% without cutting corners on core components. It also features low energy consumption and easy maintenance—daily maintenance only requires simple inspection and cleaning, reducing maintenance costs and extending service life, bringing long-term cost-saving benefits to factories.

No Extra Cost for Diverse Needs

Unlike standard machines that require additional modification costs to adapt to different lipstick styles, Ruizhi’s machine supports full non-standard customization at no extra charge for basic adjustments. Our R&D team tailors solutions according to your lipstick tube specifications, core types and assembly processes—whether it’s sample lipsticks, retractable lipsticks or special-shaped lipsticks, the machine can be flexibly adjusted to match your production line, avoiding the waste of multiple sets of equipment.

Maximize Cost Performance

High cost performance does not mean sacrificing efficiency and quality. The machine integrates automatic feeding, core installation, cap assembly and quality inspection, with a production speed of 50-70 pieces per minute, 3 times that of manual assembly. It can replace 5-7 manual workers, reducing labor costs by 35%-55% annually. Meanwhile, it adopts precision sensors to control assembly errors within ±0.02mm, ensuring product qualification rate above 99%, reducing waste and further saving production costs.

Ruizhi Intelligent Manufacturing’s Cost-Effective Non-Standard Lipstick Assembly Machine perfectly solves the cost-control pain points of cosmetic factories. With cost-saving design, free non-standard customization and efficient stable operation, it bring