Automation Technology Reshapes the Intersection of Manufacturing and Construction

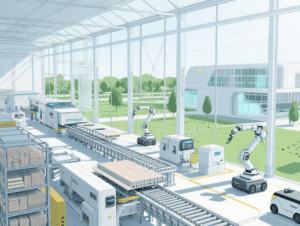

In the intersection of modern manufacturing and construction industries, automation technology is reshaping the industrial landscape with unprecedented power. Among them, the manufacturing and assembly links of industrialized construction (IC) particularly highlight this transformation trend, and automatic assembly machines, as core equipment, have become key carriers for technology integration and efficiency improvement.

Exploring the Impact of Automation on IC’s Key Stages

The integration of automation technologies has significantly improved the efficiency of industrialized construction, but to fully unleash its potential, it is still necessary to deeply explore its specific impacts in the manufacturing and assembly stages. Through a systematic review of 53 relevant articles, we can clearly see how various automation technologies act on the key stages of IC. In this process, automatic assembly machines are deployed in synergy with 22 technologies such as the Internet of Things (IoT), deep learning, digital twins, and robots, collectively promoting the progress of the industry.

Seven Core Advantages of Technological Integration in IC

The integration of these technologies has brought seven significant advantages to industrialized construction. Firstly, the improvement of interoperability enables seamless connection between different assembly machines and production systems, realizing cross-equipment data circulation and collaborative work; secondly, scheduling optimization, with the help of intelligent algorithms, makes the production plans of assembly machines more reasonable and reduces idle time; production traceability records the entire process of assembly of machined parts through IoT technology, facilitating quality control; in terms of production safety, automated operations reduce the risk of manual intervention; the improvement of manufacturability and constructability allows design schemes to be better realized through automated assembly machines; and quality assurance benefits from the high-precision operation of automated assembly machinery.

AutoML: Advancing Intelligence in Machine Assembly

Automation itself is a key concept in the field of artificial intelligence. Nowadays, artificial intelligence is moving towards its own automation, namely Automated Machine Learning (AutoML). AutoML allows algorithms to take over the construction process of machine learning models and handle tedious and repetitive tasks, which not only accelerates the development process of artificial intelligence in the field of machine assembly but also makes it easier to popularize the intelligence level of equipment such as automatic assembly machines.

Practical Lessons: The Importance of Stability in Automated Assembly

In practical applications, the value of automated assembly technology is particularly prominent. A pharmaceutical manufacturer once commissioned a system integrator to design three sets of automated machines for product assembly. These machines are essentially a special type of automatic assembly machine and need to pass FDA certification. However, after the first machine was delivered, problems occurred frequently. It shut down within less than one minute of operation, requiring three operators to be on duty, and the Overall Equipment Effectiveness (OEE) was only 10%, which seriously affected the production progress and contract performance. This case reflects that the automated assembly machinery provided by assembly suppliers and machine suppliers should not only have basic functions but also ensure stability and efficiency.

Future Challenges in Advancing IC Automation

For the field of industrialized construction, to further promote automation, future research needs to address many challenges. Improving data quality can make the intelligent decision-making of automatic assembly machines more accurate; expanding empirical tests can verify the applicability of different assembly machines in various scenarios; in-depth exploration of emerging technologies can bring more innovative solutions for the assembly of industrial parts; integrating fragmented workflows can enable mechanical parts assembly suppliers to collaborate more closely with the entire production chain.

Conclusion: Strategic Deployment of Automation as the Key

In conclusion, the strategic deployment of automation technologies, especially the optimization of the performance and application of core equipment such as automatic assembly machines, is the key to achieving seamless integration of manufacturing and assembly processes in industrialized construction. This can not only give full play to the transformative potential of automation but also open up new paths for future construction practices and manufacturing development.