Injection-molded parts—lightweight, cost-effective, and highly customizable—are ubiquitous in modern industry, from automotive dashboards and smartphone casings to medical syringes and home appliance components. As demand for precision and efficiency surges, the gap between traditional manual feeding/assembly and industrial upgrading has grown increasingly stark. Enter automatic injection-molded part feeding and assembly systems: integrated solutions that bridge injection molding machines and downstream production, automating material transfer, precision assembly, and quality validation. These systems are redefining manufacturing agility, turning “batch production” into “intelligent flow” and becoming the cornerstone of smart factories worldwide.

What Is Automatic Injection-Molded Part Feeding and Assembly?

At its core, this system is a synchronized ecosystem designed to eliminate manual intervention in two critical stages:

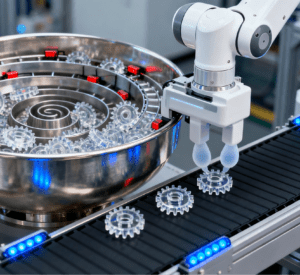

Automatic Feeding: Transferring freshly molded parts (e.g., plastic gears, connectors, or housings) from injection molding machines to assembly stations—without human hands touching the components.

Automatic Assembly: Joining multiple injection-molded parts (or combining them with metal/electronic components) into finished subassemblies or products via automated processes like snapping, screwing, welding, or bonding.

Unlike standalone feeding robots or assembly lines, this integrated system leverages machine vision, sensor fusion, and intelligent control to adapt to the unique challenges of injection-molded parts: their lightweight nature, complex geometries, and susceptibility to damage. It ensures a seamless “mold-to-assembly” flow, where parts move from the injection press to final inspection with minimal downtime or errors.

Core Technologies: How the System Works

The magic of automatic feeding and assembly lies in its synergistic technologies, each addressing a specific pain point in handling injection-molded parts. Here’s a breakdown of its key components:

- Adaptive Feeding: From Mold to Assembly, Without a Hitch

Feeding injection-molded parts is trickier than it seems. Parts may be sticky (due to residual mold release agents), fragile (thin-walled components), or irregularly shaped (e.g., curved housings). The feeding system solves this with:

Multi-Mode Part Handling:

For small, uniform parts (e.g., plastic clips), vibration bowls with precision-machined tracks sort and orient parts via controlled vibrations, ensuring they exit in a consistent “up/down” posture.

For large or delicate parts (e.g., automotive door panels), 6-axis collaborative robots with custom grippers (soft silicone for fragile parts, vacuum cups for flat surfaces) gently extract parts from mold cavities, avoiding scratches or deformation.

For high-volume, high-speed scenarios (e.g., smartphone charger casings), conveyor systems with vision-guided diverters route parts to parallel assembly lines, preventing bottlenecks.

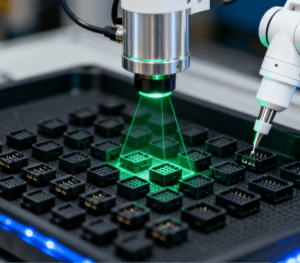

In-Process Cleaning & Inspection:Feeding isn’t just about movement—it’s about quality. Integrated air blowers remove dust or debris from parts post-molding, while inline cameras check for surface defects (e.g., flash, warpage) before feeding. Defective parts are automatically diverted to a reject bin, preventing downstream assembly errors.

- Precision Assembly: Adapting to the “Personality” of Injection-Molded Parts

Injection-molded parts often require tight tolerances (e.g., ±0.05 mm for gear assemblies) and gentle handling to avoid cracking. The assembly unit meets these demands with:

Flexible Fixturing:Custom jigs made from low-friction materials (e.g., POM plastic) secure parts during assembly, with quick-change designs allowing switchovers between part models in 5–10 minutes—critical for small-batch, multi-variety production (e.g., custom medical device components).

Force-Controlled Robotic Arms:4-axis or 6-axis robots equipped with force-torque sensors “feel” their way through assembly. For example, when snapping a plastic cover onto a housing, the robot adjusts pressure in real time: too much force risks cracking the part; too little, and the fit is loose. This precision reduces scrap rates by up to 80% compared to manual assembly.

Hybrid Joining Technologies:Depending on part requirements, the system integrates ultrasonic welders (for plastic-to-plastic bonding), automatic screw feeders (for threaded connections), or UV curing stations (for adhesive bonding). For instance, in assembling a water pump housing, the system might first weld two plastic halves, then insert and tighten metal screws—all in a single cycle.

- Intelligent Control: The “Brain” That Keeps It All in Sync

A centralized control system acts as the conductor, ensuring feeding, assembly, and inspection work in harmony:

PLC & HMI Integration: A programmable logic controller (PLC) coordinates timing between injection molding machines, feeders, and robots, while a human-machine interface (HMI) lets operators monitor real-time metrics (e.g., parts per minute, defect rate) and tweak parameters (e.g., gripper pressure) with a touchscreen.

Machine Vision as the “Eyes”:High-resolution cameras (up to 20MP) mounted at key stations verify part orientation before assembly, check alignment during joining, and inspect final dimensions. AI algorithms can even learn to recognize new defect patterns over time, improving accuracy.

MES Data Linkage: The system feeds data (e.g., cycle time, material usage, defect types) to the factory’s Manufacturing Execution System (MES), enabling traceability. If a batch of parts fails inspection, MES can trace the issue back to a specific injection mold or assembly station, accelerating root-cause analysis.

Real-World Impact: Transforming Industries

Automatic injection-molded part feeding and assembly systems are not just “nice-to-have”—they’re game-changers across sectors where precision and scale matter:

Automotive: Speeding Up EV Component Production

In electric vehicle (EV) manufacturing, plastic components like battery case seals, charging port housings, and dashboard clips demand high consistency. A leading auto parts supplier in Zhejiang deployed such a system to assemble battery terminal insulators:

Feeding: Robots extract injection-molded insulators from 8-cavity molds and place them into alignment trays.

Assembly: Force-controlled arms press metal terminals into the insulators, with vision systems verifying terminal depth.

Result: Production capacity increased by 40% (from 500 to 700 units/hour), while defect rates dropped from 2% to 0.1%.

Consumer Electronics: Micro-Assembly for Tiny Parts

Smartphones and wearables rely on micro-injection-molded parts (e.g., camera lens holders, connector housings) that are smaller than a fingernail. A Shenzhen-based electronics manufacturer uses the system to assemble wireless earbud casings:

Feeding: Vibratory bowls sort 3mm plastic gaskets, while robots pick 5mm speaker grilles from trays.

Assembly: A 6-axis robot with a 0.5mm-diameter gripper aligns and bonds the gasket to the grille, with UV curing in-line.

Result: Manual labor reduced by 70%, and assembly time per unit cut from 45 seconds to 12 seconds.

Medical Devices: Compliance and Cleanliness

Medical injection-molded parts (e.g., syringe plungers, inhaler components) require strict sterility and traceability. A European medical device firm integrated the system into its cleanroom production:

Feeding: Stainless steel conveyors with HEPA-filtered air ensure parts remain sterile post-molding.

Assembly: Robots with disposable grippers assemble syringe barrels and plungers, with each part tracked via QR codes.

Result: Compliance with FDA and ISO 13485 standards, plus a 30% reduction in rework due to contamination.

Why Invest? The Competitive Edge

For manufacturers, the benefits of automatic feeding and assembly extend far beyond “automation for automation’s sake”:

Efficiency: 24/7 operation eliminates shift gaps, boosting output by 30–60% compared to manual lines.

Quality: Machine vision and force control reduce defects to near-zero, critical for industries like automotive and medical.

Cost Savings: Replacing 3–6 workers per line cuts labor costs by 50–70% annually, with ROI typically achieved in 12–18 months.

Flexibility: Quick-change tooling and programmable robots adapt to new part designs, helping manufacturers respond to market demands faster.

The Road Ahead: Smarter, Greener, More Connected

As Industry 4.0 evolves, these systems are set to become even more intelligent:

AI-Powered Predictive Maintenance: Sensors in robots and feeders will detect wear (e.g., gripper degradation) and schedule maintenance before failures occur, cutting downtime by 25%.

Digital Twins: Virtual replicas of the system will let engineers simulate new part assemblies, test parameters, and optimize workflows without disrupting production.

Sustainability: Energy-efficient motors, recyclable gripper materials, and waste-reducing feeding (e.g., precise part counting) will lower carbon footprints by 15–20%.

Conclusion

Automatic injection-molded part feeding and assembly is more than a technology—it’s a paradigm shift. By turning chaotic, manual processes into streamlined, data-driven flows, it empowers manufacturers to compete in a world where precision, speed, and flexibility are non-negotiable. As injection-molded parts continue to dominate modern products, these systems will remain the unsung heroes of smart manufacturing, proving that the future of production lies not in replacing humans, but in equipping them with tools that turn possibility into productivity.