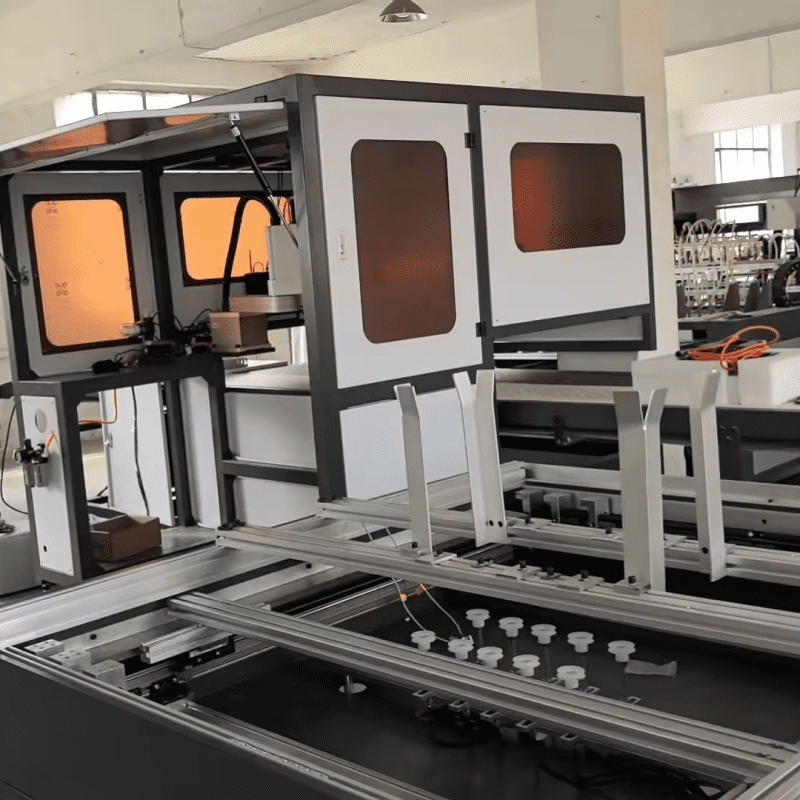

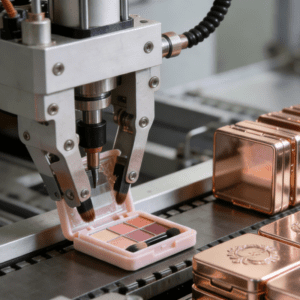

Eyeshadow cases feature diverse designs—varying in size, shape, material, and compartment structure—leading to frequent batch changes in cosmetic production. Traditional assembly equipment or manual operations struggle with these changes, causing prolonged downtime, unstable quality, and increased costs. Ruizhi Intelligent Manufacturing’s full-automatic non-standard eyeshadow case assembly machine targets these pain points, offering customized solutions to make batch switching efficient and smooth.

Quick-Change Fixture System: Cut Batch Switching Downtime

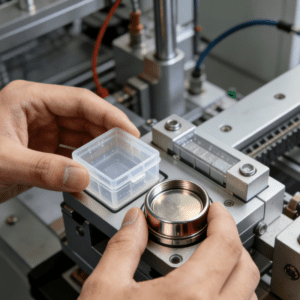

The biggest hurdle in batch changes is time-consuming fixture adjustment. Ruizhi’s machine is equipped with a customized quick-change fixture system, tailored to different eyeshadow case specifications. We optimize fixture structure and positioning modules, enabling operators to complete fixture replacement in 5 minutes or less—reducing downtime by over 70% compared to standard equipment. The machine adapts to various case materials, from plastic to metal, and compartment designs, supporting seamless switching between small-batch customization and large-scale mass production.

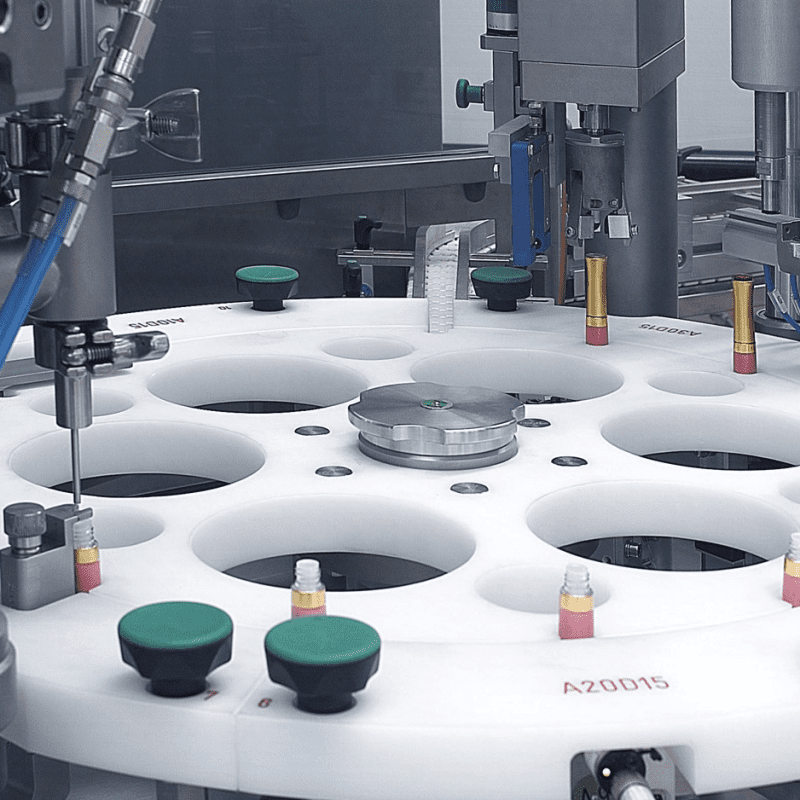

Intelligent Calibration & Detection: Stable Quality Across Batches

Batch changes often lead to quality fluctuations, such as misaligned compartments, loose hinges, or uneven bonding. Our machine integrates advanced visual recognition and PLC intelligent control, automatically calibrating positioning parameters when switching batches. Built-in pressure detection and appearance inspection functions real-time monitor assembly accuracy, eliminating defects and ensuring consistent quality across different batches. With a production speed of up to 3600 pieces per hour, it replaces 6-8 manual workers, balancing efficiency and stability.

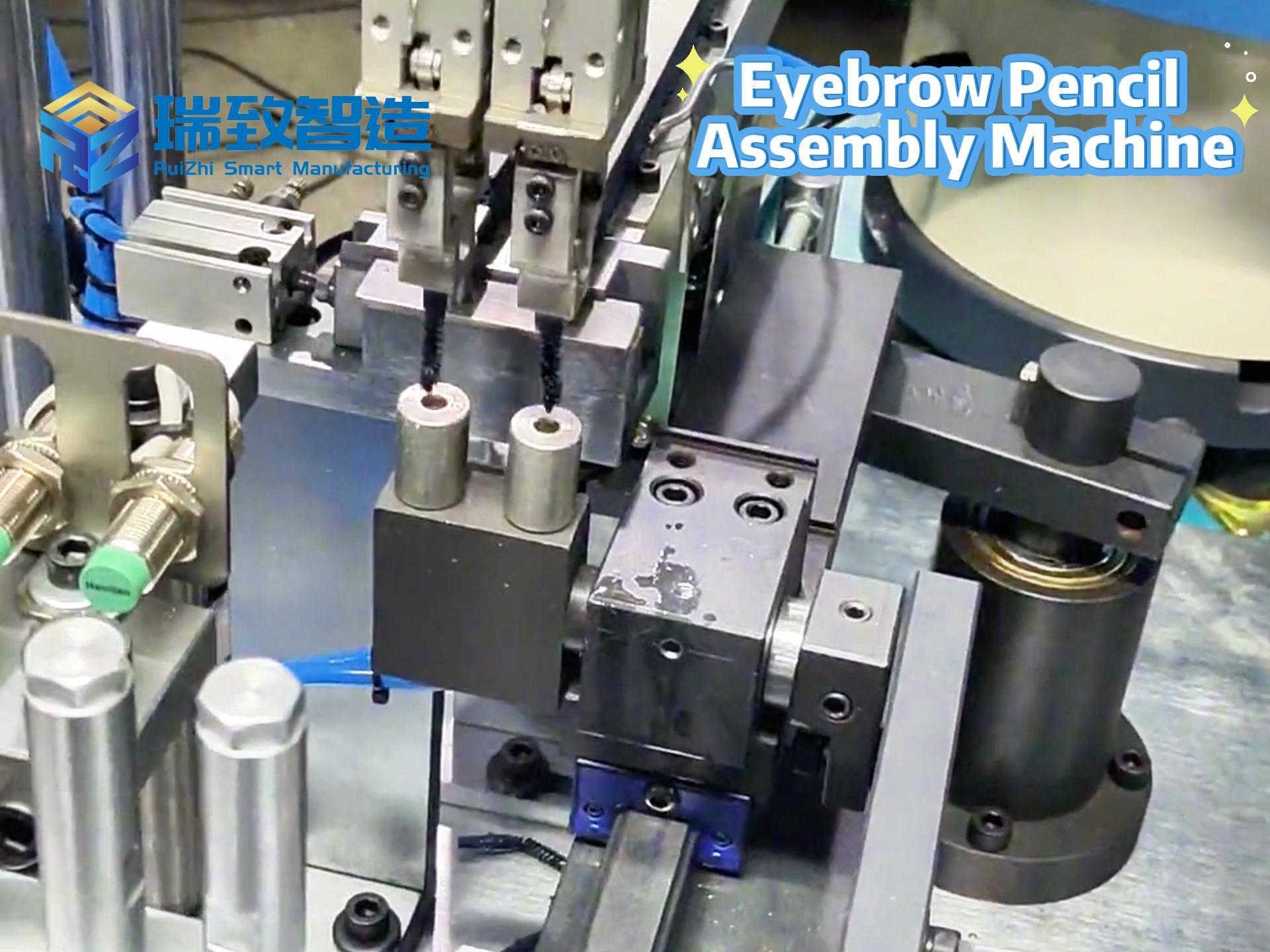

Non-Standard Customization & Comprehensive Support: Adapt to Diverse Needs

Eyeshadow case designs are constantly updated, and standard machines cannot keep up with personalized needs. Ruizhi provides one-stop non-standard customization, from demand analysis and structure design to equipment debugging, based on clients’ specific case designs. Adhering to FDA and GMP standards, all contact parts use food-grade materials for safe production. We also offer on-site training and 24/7 after-sales support, resolving technical issues during batch changes promptly and ensuring uninterrupted production.

Ruizhi Intelligent Manufacturing’s full-automatic eyeshadow case assembly machine solves batch change troubles with professional non-standard customization, intelligent technology, and reliable support, empowering cosmetic enterprises to achieve flexible, efficient, and high-quality production.