Factors Influencing Assembly Machine Costs and Procurement Guide: From Pricing Logic to Informed DecisionsIn the wave of automation transformation in the manufacturing industry, assembly machines have become core equipment to address key challenges such as “efficiency bottlenecks,” “quality fluctuations,” and “rising labor costs.” Whether small and medium-sized enterprises (SMEs) are seeking “cost reduction and efficiency improvement” or large enterprises are deploying “flexible production,” procurement decisions for assembly machines directly impact the competitiveness of production chains. However, the price of assembly machines is not a fixed figure—it varies drastically, ranging from tens of thousands of RMB for standardized single machines to tens of millions of RMB for customized production lines. This article systematically breaks down the core factors influencing assembly machine pricing, sorts out the cost ranges of mainstream models, quantifies investment value, and provides a key framework for procurement decisions to help enterprises accurately match their needs with budgets.

Assembly Machine Pricing: 6 Core Influencing Factors

The cost difference of assembly machines essentially stems from the matching of “demand complexity” and “technical configuration.” The following 6 dimensions directly determine price trends:

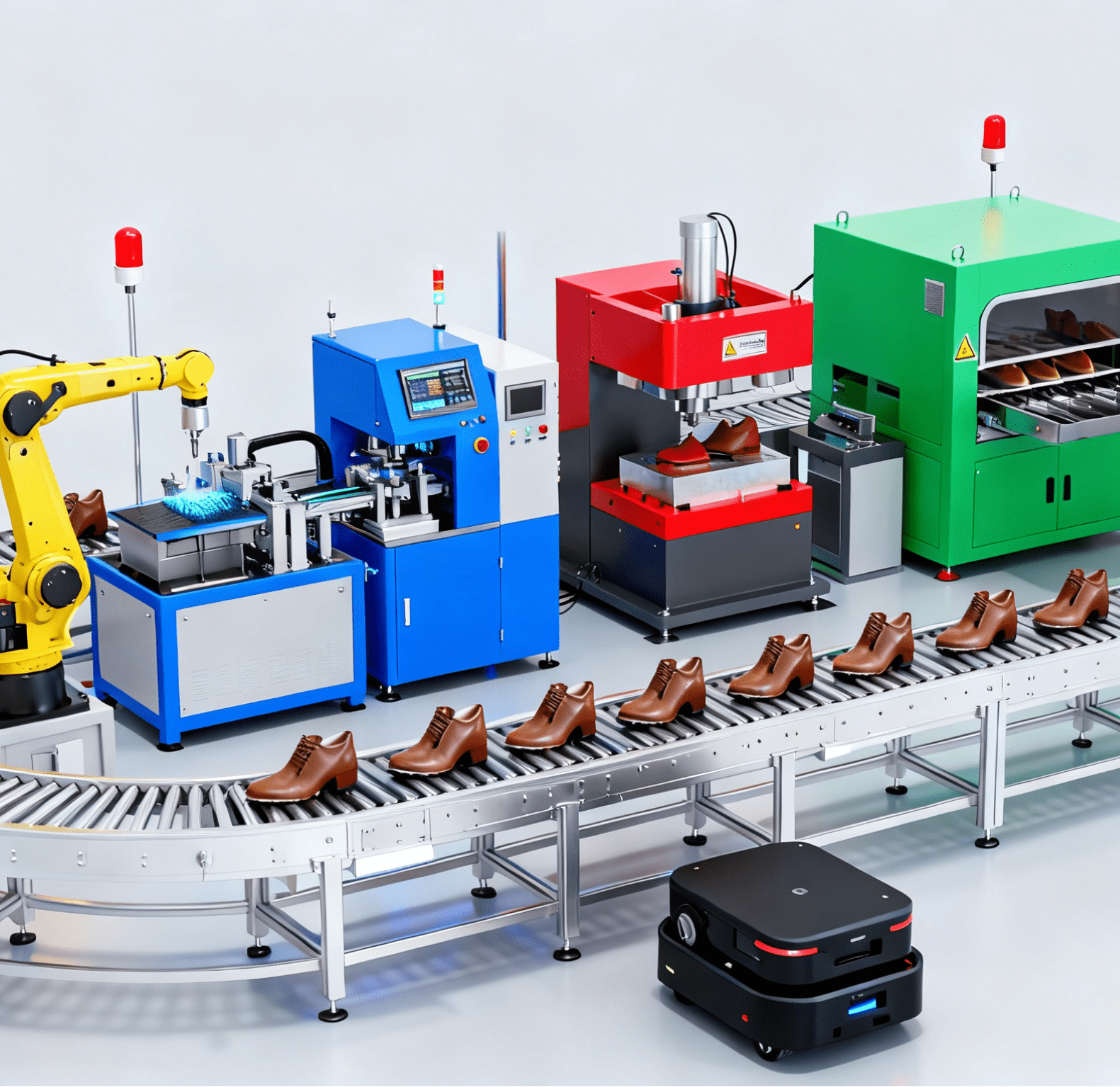

Machine Type and Functional Complexity: The Baseline for PricingDifferent types of assembly machines have vastly different price starting points due to differences in core functions:Simple Semi-Automatic Machines: These machines perform only a single assembly action (e.g., screw tightening, part press-fitting) and rely on manual assistance for loading/unloading. They are suitable for small-batch production (e.g., assembly of small hardware parts). For example, a semi-automatic screw assembly machine (equipped with a manual feeding table and single-axis tightening mechanism) typically costs 30,000–150,000 RMB, mainly meeting the needs of small workshops or low-capacity production.Fully Automatic Single Machines: Integrating automatic feeding, assembly, and inspection functions, these machines require no manual intervention (e.g., fully automatic O-ring installation machines, PCB insertion machines). They are suitable for medium-batch, single-product production. Taking the fully automatic insertion machine commonly used in the electronics industry as an example—it can simultaneously complete the insertion and inspection of resistors and capacitors—its price ranges from 200,000–800,000 RMB, with a production capacity of 300–500 pieces per minute.Modular Assembly Lines: Composed of multiple single machines connected via a conveyor system, these lines enable multi-process collaboration (e.g., feeding → press-fitting → welding → inspection → unloading). They are suitable for large-batch, multi-process products (e.g., automotive parts, home appliance assemblies). For instance, a simplified automotive door handle assembly line (including 3 assembly machines + conveyor belt + visual inspection) usually costs 1–5 million RMB, depending on the number of processes.Customized Flexible Production Lines: Integrating robotics, AGVs (Automated Guided Vehicles), and digital twin technology, these lines can quickly switch product models (e.g., a single line adapting to the assembly of 3–5 specifications of vacuum blood collection tubes). They are suitable for multi-variety, medium-batch production (e.g., medical equipment, high-end electronics). Due to the need for customized mechanical structures and dedicated control software development, such production lines generally cost 5–20 million RMB, or even more (e.g., high-precision assembly lines for aerospace parts).

Degree of Customization: More Specialized Needs = Higher CostsStandardized machines have lower costs due to mass production, while customized needs significantly increase prices, mainly reflected in three aspects:Structural Customization: Designing dedicated fixtures and conveyor tracks for special part shapes (e.g., irregular plastic parts, ultra-thin metal parts) requires re-molding and testing, increasing costs by 20%–50%. For example, developing a “breakage-proof feeding mechanism” for vacuum blood collection tubes (to avoid scratching glass tubes) requires an additional 150,000–300,000 RMB in R&D and manufacturing costs.Process Customization: Integrating non-standard assembly processes (e.g., aseptic assembly, high-temperature welding) requires adaptation to special environments or process parameters. For instance, syringe assembly machines in the medical industry need to meet GMP cleanroom standards (Class 10,000), requiring the addition of HEPA filtration systems and aseptic disinfection modules—costing 30%–60% more than ordinary machines.Software Customization: Developing dedicated control programs (e.g., connecting to enterprise MES systems, enabling full-process data traceability) requires programmers to write algorithms based on needs. The one-time development cost usually ranges from 100,000–500,000 RMB, and complex flexible scheduling software can even exceed 1 million RMB.

Production Capacity and Efficiency Indicators: “Speed” Directly Links to Hardware CostsThe production capacity of an assembly machine (number of assemblies completed per unit time) is determined by core hardware (e.g., servo motors, robotic arms, conveyor speed). Higher capacity requires higher hardware specifications, leading to higher prices:Low Capacity (<100 pieces/minute): Adopting single-axis drive and simple conveyor belts, suitable for small parts (e.g., micro-screw assembly), prices range from 100,000–300,000 RMB.Medium Capacity (100–500 pieces/minute): Requiring multi-axis collaboration, high-precision servo motors (e.g., Panasonic A6 series), and synchronized conveyor belts, prices range from 300,000–1.5 million RMB (typical examples include electronic component insertion machines).High Capacity (>500 pieces/minute): Relying on high-speed robotic arms (e.g., ABB IRB 360), continuous-motion conveyor systems, and even multi-machine parallel operation, prices generally exceed 1.5 million RMB. For example, a beverage bottle cap assembly line (with a capacity of up to 2,000 pieces/minute) costs over 3 million RMB per line.

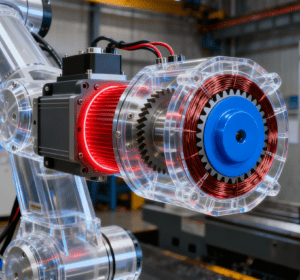

Technical Configuration: Premium for “Precision” and “Intelligence”The core technical configuration of assembly machines (e.g., sensors, vision systems, control systems) directly affects precision and intelligence levels, and is also a key source of price differences:Precision Configuration: Ordinary machines use photoelectric sensors (positioning accuracy ±0.1mm) to meet general needs; high-precision machines require laser displacement sensors (±0.005mm) and torque sensors (controlling assembly force error within ±2%), increasing costs by 50%–100%. For example, an automotive gearbox bearing press-fitting machine (requiring ±0.01mm press-fitting precision) is 80%–120% more expensive than ordinary press-fitting machines.Intelligence Configuration: Basic models are only equipped with PLC control (e.g., Siemens S7-1200) to support simple program adjustments; high-end models integrate machine vision (e.g., Cognex In-Sight cameras), AI defect detection, and remote operation and maintenance modules, enabling “automatic positioning, abnormal alarms, and data upload.” The cost of such intelligent modules can account for 20%–40% of the total machine cost. For example, a robot assembly unit with vision guidance is 300,000–800,000 RMB more expensive than the version without vision.

Brand and Supply Chain: Hidden Costs of Quality and ServiceAssembly machines from different brands have distinct price tiers due to differences in R&D investment, quality control standards, and after-sales service:Domestic SME Brands: Focusing on standardized models with low R&D costs, their prices are 30%–50% lower than imported brands. Suitable for enterprises with limited budgets and conventional needs (e.g., hardware, small home appliance manufacturing), but after-sales service response times may be longer (24–72 hours).Domestic Leading Brands (e.g., Han’s Laser, Sunwoda Intelligent): Focusing on the mid-to-high-end market, they possess independent core technologies (e.g., dedicated welding algorithms) and strict quality control. Their prices are 20%–30% higher than SME brands, but they provide 1 year of free maintenance and on-site service within 48 hours—suitable for industries with high stability requirements (e.g., new energy, automotive parts).Imported Brands (e.g., Bosch Germany, Fanuc Japan): Leading in technology with outstanding precision and reliability (MTBF > 10,000 hours), their prices are 1.5–2 times that of domestic leading brands. They mainly serve high-end manufacturing (e.g., aerospace, medical equipment), but spare parts procurement cycles are long (1–3 months) and maintenance costs are high.

After-Sales Service: Hidden Costs for Long-Term ValueThe procurement cost of assembly machines includes not only the equipment itself but also long-term after-sales service costs, which are often overlooked by enterprises:Basic Services: Most brands include 1 year of free warranty, equipment installation and commissioning, and operator training—these costs are already included in the equipment price. After the warranty period, a single on-site maintenance service costs approximately 2,000–5,000 RMB (domestic brands) or 5,000–15,000 RMB (imported brands).Value-Added Services: These include regular maintenance (once per quarter, annual fee: 50,000–200,000 RMB), spare parts storage (customized spare parts require advance procurement, costing 5%–10% of the total equipment price), and software upgrades (1–2 times per year, cost: 20,000–100,000 RMB). Although these services increase short-term costs, they can extend equipment lifespan (from 5 years to 8–10 years) and reduce unplanned downtime losses.

Mainstream Assembly Machine Types and Cost Ranges

Different machine types have distinct application scenarios and price differences. Enterprises should choose based on their product characteristics and production capacity needs. Below is a detailed comparison of 5 core machine types:

Automated Conveyor Assembly Lines

Core Function: Convey parts to various assembly stations via conveyor belts, enabling continuous operations of “feeding → assembly → inspection → unloading” and supporting large-batch, single-product production.

Application Scenarios: Food packaging (e.g., milk carton assembly), home appliance accessories (e.g., washing machine motor assembly), simple hardware (e.g., hinge assembly).

Cost Range:

Simplified version (2–3 processes, no visual inspection): 500,000–1.5 million RMB;

Standard version (4–6 processes, with basic inspection): 1.5–3 million RMB;

High-end version (6+ processes, with visual positioning and data traceability): 3–8 million RMB.

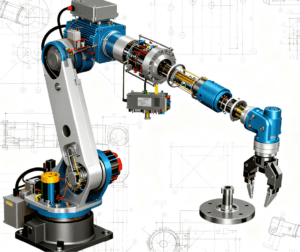

Robotic Assembly Units

Core Function: Centered on 1–4 industrial robots (e.g., 6-axis robotic arms) and equipped with dedicated fixtures, they complete complex assembly actions (e.g., multi-part splicing, precision welding) and support flexible model switching.

Application Scenarios: Automotive parts (e.g., gearbox gear assembly), high-end electronics (e.g., mobile phone camera module assembly), medical equipment (e.g., syringe plunger assembly).

Cost Range:

Single-robot unit (including 1 domestic robot + basic fixtures): 200,000–500,000 RMB;

Multi-robot unit (2–4 domestic robots + vision system): 500,000–1.5 million RMB;

Imported robot unit (1–2 Fanuc/ABB robots + customized software): 1.5–4 million RMB.

Indexing Assembly Machines (Rotary/In-Line Indexing)

Core Function: Convey parts to each station step-by-step via a rotating table (rotary type) or linear track (in-line type), with each station completing a single process—offering high precision and stability.

Application Scenarios: Small precision parts (e.g., sensors, micro-motors), medical consumables (e.g., vacuum blood collection tubes, diagnostic reagent cards).

Cost Range:

Rotary indexing machine (6–8 stations, manual feeding): 100,000–300,000 RMB;

In-line indexing machine (10–12 stations, automatic feeding): 300,000–800,000 RMB;

High-precision indexing machine (with laser inspection, positioning accuracy ±0.005mm): 800,000–2 million RMB.

Flexible Feeding Assembly Systems

Core Function: Integrating vibratory bowls, visual sorting, and AGV modules, they can adapt to parts of various sizes/shapes (e.g., circular, square, irregular parts) without frequent fixture replacement.

Application Scenarios: Multi-variety, small-batch production (e.g., customized hardware, non-standard electronic components), industries with high demand for quick model switching (e.g., 3C product OEMs).

Cost Range:

Basic flexible system (adapting to 2–3 part types, no AGV): 300,000–800,000 RMB;

Advanced flexible system (adapting to 5–8 part types, with AGV conveyance): 800,000–2 million RMB;

High-end flexible system (adapting to 10+ part types, connecting to digital twin platforms): 2–6 million RMB.

Automātiska ātrās savienošanas detaļu montāžas mašīna

Core Function: Specialized in the automated assembly of quick-connect components (e.g., hydraulic quick couplings, pneumatic plug-in joints, fluid pipeline connectors), it integrates functions such as automatic part orientation (via vibratory bowls + 2D vision positioning), precision insertion (controlled by servo motors to ensure coaxiality), and connection tightness detection (via pressure feedback sensors or airtightness testing modules). It can prevent assembly failures caused by misalignment or incomplete insertion of quick-connect parts.

Application Scenarios: Automotive hydraulic systems (e.g., brake pipeline quick-coupling assembly), pneumatic tool manufacturing (e.g., air wrench quick-connect joint installation), home appliance waterway systems (e.g., washing machine inlet pipe connector assembly), and industrial fluid equipment (e.g., chemical pipeline quick-connect assembly).

Cost Range:

Basic version (single-spec quick-connect parts, no tightness testing): 200,000–500,000 RMB;

Standard version (adapting to 3–5 specs, with pressure feedback testing): 500,000–1.2 million RMB;

High-end version (adapting to 8+ specs, with airtightness testing + MES system docking): 1.2–3 million RMB.

Conclusion: Matching Needs to Balance Cost and Value

The “price” of an assembly machine is never a single number but a balance between “demand complexity” and “technical value.” For SMEs, priority should be given to standardized models (e.g., semi-automatic screw assembly machines, basic indexing machines) to control initial investment and quickly achieve “cost reduction and efficiency improvement.” For large enterprises or high-end manufacturing fields (e.g., automotive, medical), customized and intelligent models should be selected based on long-term production capacity planning and quality requirements to build competitive barriers through technological investment.Ultimately, an informed procurement decision is not about “buying the cheapest” but “buying the most suitable.” By accurately defining needs, evaluating total cost of ownership, and verifying supplier capabilities, assembly machines can become a “value-adding engine” for production chains rather than just a “cost burden.”