Turn-mill compound machining technology is gradually reshaping the landscape of modern manufacturing industry. It enables integrated turning and milling operations via intelligent CNC machining equipment, efficiently processing rotational parts (e.g., shaft-type components) and non-rotational parts (e.g., box-type components). This one-stop machining solution not only simplifies the production process, but also significantly improves processing efficiency and precision, while reducing costs and time waste. This paper explores in depth the core principles, innovative production strategies and practical application cases of this technology, helping readers fully understand its industrial value.

Core Technology of Turn-mill Compound Machining

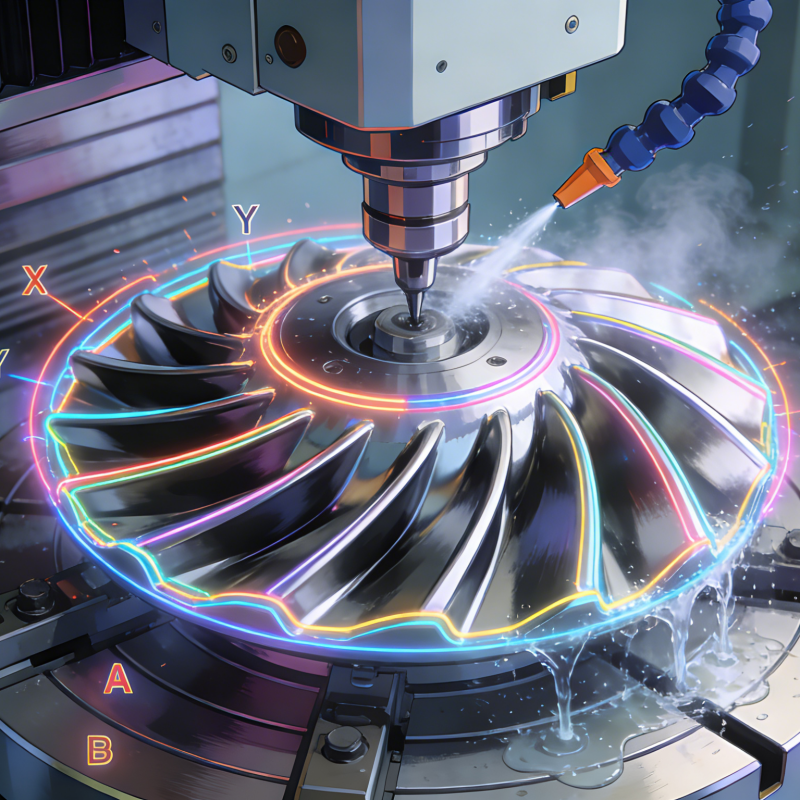

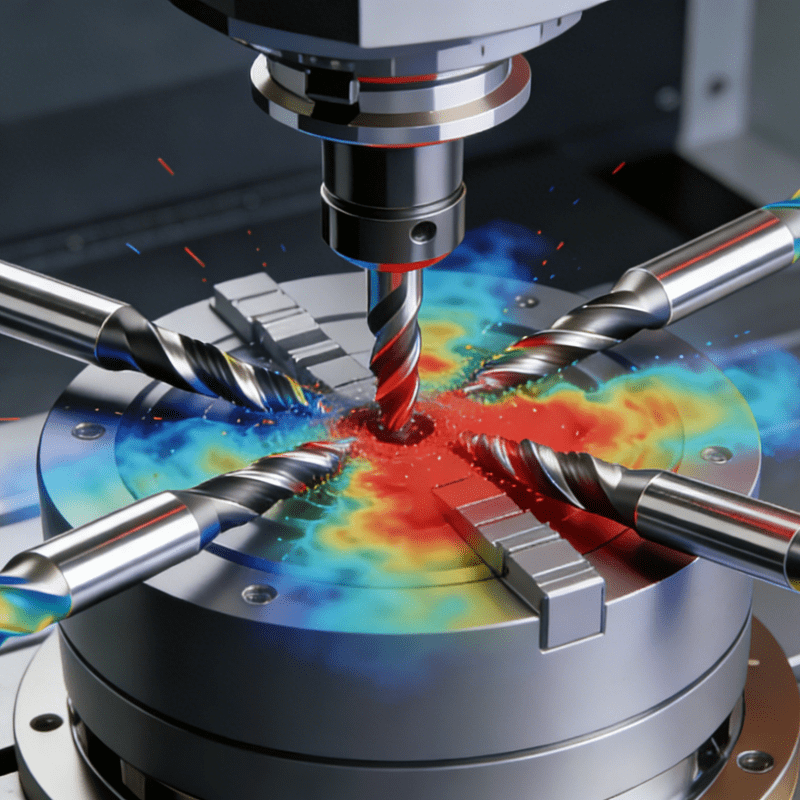

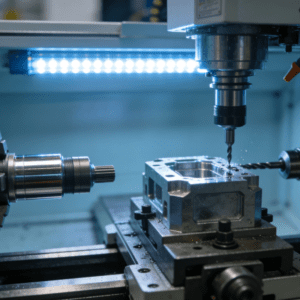

The core advantage of turn-mill compound machining lies in its highly integrated processing capability. By integrating the traditional functions of turning (rotational machining) and milling (non-rotational machining) into a single advanced intelligent CNC machine tool, it breaks the limitations of separated machining procedures. The core of such equipment is equipped with an electric spindle with high torque and high speed performance, as well as a powerful power turret (or B-axis). The electric spindle drives the workpiece to rotate, enabling the machining of typical rotational parts such as external cylindrical turning, inner hole turning and face turning. Meanwhile, the power turret can drive milling cutters, drills and other tools to perform precise milling, drilling, tapping and other machining tasks for non-rotational parts with complex contours, planes or special-shaped features, whether the workpiece is stationary or rotating. This seamless switching capability to complete multiple processes in a single workspace with one-time clamping is the fundamental basis for turn-mill compound technology to achieve high-efficiency production and guaranteed machining precision.

A New Solution for High-efficiency Production

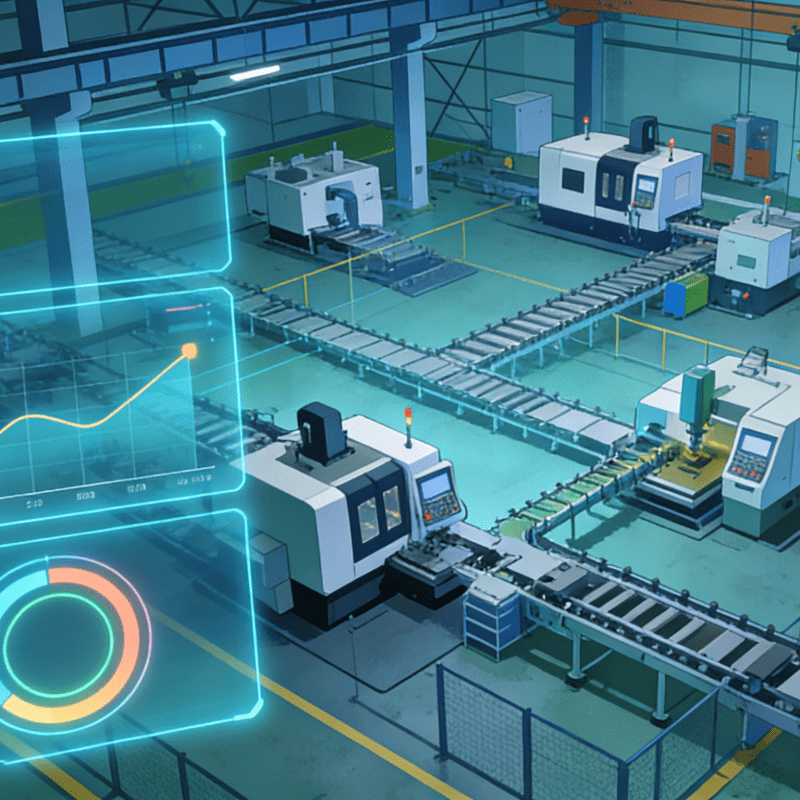

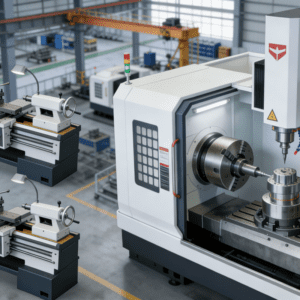

Based on turn-mill compound machining technology, intelligent CNC machine tools have realized a new high-efficiency production solution through an integrated operation mode. This solution can process rotational and non-rotational parts simultaneously without frequent equipment replacement or repeated workpiece clamping, thus greatly shortening the machining cycle. The improvement of production efficiency stems from the simplification of processes, such as reducing intermediate transportation and waiting time, while machining precision is well guaranteed. In addition, this high-efficiency production method can effectively reduce production costs in terms of labor, energy consumption and material waste.

Comprehensive Machining of All Kinds of Parts

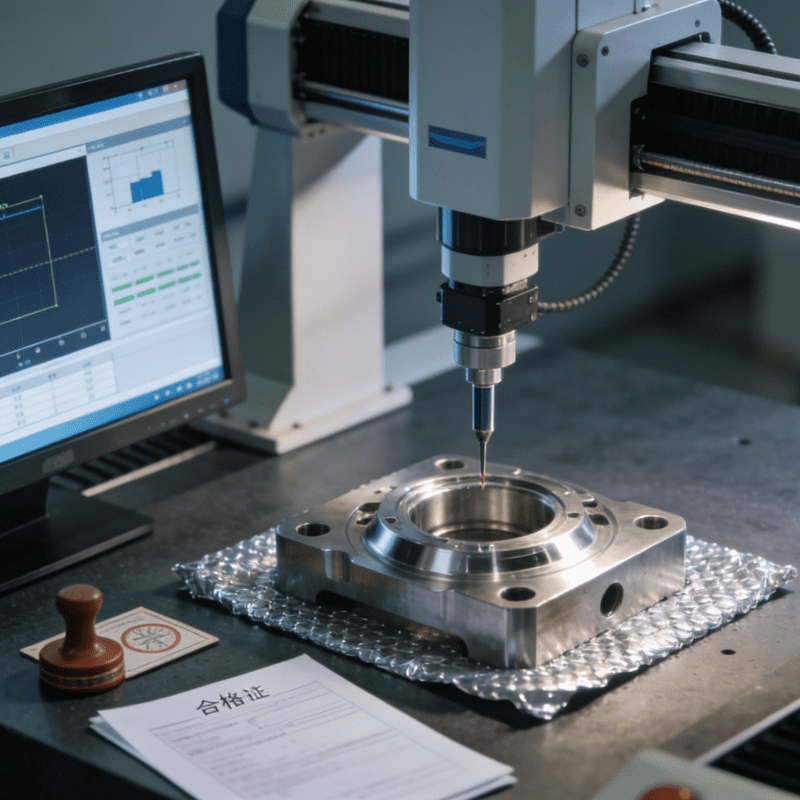

Through the integrated operation of intelligent CNC machine tools, turn-mill compound machining technology fully covers the machining requirements of various types of parts. Whether it is the machining of rotational parts such as shafts and gears that require high-speed rotation, or the machining of non-rotational parts such as box bodies involving planes and complex contours, this technology can efficiently complete all processes with a single clamping. Notably, this one-stop machining advantage is also widely applied in the production of Katetra montāžas mašīna core components: the key parts of catheter assembly machines (such as precision rotational guide shafts and non-rotational positioning brackets) often integrate both rotational and non-rotational structural features, and turn-mill compound machining can finish all machining processes in one clamping, ensuring the coaxiality and position accuracy between different components—critical for the stable operation of catheter assembly equipment in medical device manufacturing. This seamless switching capability eliminates the frequent equipment replacement steps in traditional machining, thus greatly improving machining precision and production efficiency. At the same time, the intelligent control of the intelligent machining system ensures the automatic optimization of machining parameters for different part types, helping manufacturers easily cope with the challenges of diversified production.

Turn-mill compound machining technology successfully integrates the processing needs of rotational and non-rotational parts through the integrated operation of intelligent CNC machine tools, eliminating the cumbersome procedures of traditional step-by-step processing. This high-efficiency production method significantly shortens the manufacturing cycle, improves machining precision, and reduces equipment investment and labor costs at the same time. In practical applications, it provides a reliable one-stop solution for the manufacturing industry, which not only optimizes resource utilization, but also enhances overall competitiveness. With the continuous evolution of technology, turn-mill compound machining will continue to drive innovation and progress in industrial production.