In the medical industry, the quality and precision of medical components are directly related to patients’ lives, health, and treatment outcomes. CNC (Computer Numerical Control) precision machining, especially CNC machining technology, has become a key method for medical component processing due to its excellent precision control capabilities, playing a pivotal role in the field of precision part machining.

The Importance of CNC Precision Machining in Medical Component Manufacturing

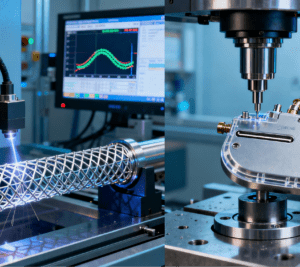

The special nature of medical components determines their strict requirements for precision. For example, artificial joints need to fit perfectly with human bones, and vascular stents must expand accurately inside blood vessels and provide stable support. Even an extremely small dimensional deviation may cause the implant to fail to work properly, or even lead to serious medical accidents. CNC precision machining can achieve micron-level or even higher precision, ensuring the dimensional accuracy and surface quality of medical components to meet the high-standard requirements of the medical industry.

Key Technologies and Processes for Medical Component Machining

High-Precision Programming

Before CNC machining of medical components, programmers need to accurately plan the tool path using professional Computer-Aided Manufacturing (CAM) software based on design drawings. Every cutting action and every feed rate is carefully calculated to ensure that the machined parts meet the design requirements. For instance, when machining dental implants with complex shapes, programming must take into account their unique thread structure and surface roughness requirements. By optimizing the tool path, the precise shape and good biocompatibility of the implants are guaranteed.

Selection of Advanced Cutting Tools and Cutting Parameters

Appropriate cutting tools must be selected for different medical component materials, such as titanium alloys and stainless steels. For example, when machining titanium alloys, tools with high temperature resistance and good wear resistance should be used to cope with the difficulty of processing this material. At the same time, precise control of parameters such as cutting speed, feed rate, and cutting depth is crucial. These parameters not only affect processing efficiency but also are directly related to the precision and surface quality of the parts. Improper parameters may cause defects such as scratches and deformation on the part surface, affecting the performance of medical components.

Strict Processing Environment Control

The processing of medical components has extremely high requirements for the environment. Minor changes in temperature and humidity may affect processing precision. In precision part processing workshops, constant temperature and humidity systems are usually equipped to control temperature and humidity within a very small fluctuation range. In addition, the stability of processing equipment is also crucial—integrating sheet automatic loading robots into the production line has become a key measure to enhance precision and consistency. These robots can automatically transport medical-grade sheets (such as titanium alloy or medical stainless steel sheets) to CNC machining stations with micron-level positioning accuracy, avoiding surface contamination and dimensional deviations caused by manual handling, while ensuring continuous and stable feeding in a clean processing environment. Regular maintenance and calibration of CNC machining equipment and auxiliary automation devices like these robots are conducted to ensure they are always in the optimal operating state.

Applications of CNC Precision Machining in Different Medical Components

Surgical Instruments

Surgical instruments such as scalpels and forceps require extremely high precision and sharpness. CNC precision machining can produce instruments with sharp edges and accurate dimensions, ensuring the accuracy and reliability of surgical operations. For example, ophthalmic surgical instruments manufactured using CNC precision machining have a level of refinement that meets the needs of micro-operations in ophthalmic surgery, reducing damage to eye tissues.

Implantable Medical Devices

Implantable medical devices such as cardiac pacemaker housings and artificial joints have extremely high requirements for biocompatibility and precision. CNC precision machining can ensure the surface smoothness and dimensional accuracy of these components, reducing the body’s rejection of implants and improving the success rate of implantation and service life.

Quality Inspection and Control

After the processing of medical components is completed, strict quality inspection is essential. Precision testing equipment such as coordinate measuring machines and optical microscopes are used to conduct comprehensive inspections of the part’s dimensional accuracy, shape accuracy, and surface roughness. Any components that do not meet the standards cannot enter the medical market. At the same time, a sound quality traceability system is established. In case of problems, it can quickly trace all links in the processing process, including data from sheet automatic loading robots (such as feeding time, positioning parameters, and material information), and take timely improvement measures.

With its advantages of high precision and high stability, CNC precision machining provides reliable technical support for the processing of medical components. As medical technology continues to develop, the requirements for the precision and quality of medical components will keep increasing. CNC precision machining technology, along with supporting automation equipment like sheet automatic loading robots, will also continue to innovate and improve, driving the medical industry to a higher level.