CNC precision manufacturing refers to an advanced production method that uses computer numerical control technology for high-precision processing of materials. Our applications in this field cover multiple industries such as medical devices, aerospace, and automotive manufacturing. In the medical sector, CNC technology is widely used to produce a variety of precision components with complex shapes, including prosthetics, implants, and surgical instruments. In these applications, CNC manufacturing can not only meet extremely sophisticated design requirements but also satisfy strict quality standards and safety needs.

Through CNC machining, we can transform design drawings into actual products with high repeatability, which is particularly crucial for the medical industry. With highly automated and intelligent processing procedures, we ensure the consistency and reliability of components. In addition, CNC technology supports rapid prototyping, enabling us to conduct multiple iterations in a short period and adjust product designs promptly to adapt to evolving market demands and technological advancements.

With its widespread adoption, CNC precision manufacturing has become a key driver of the development of medical equipment. This technology plays an important role in improving production efficiency and ensuring product quality, providing strong support for the pharmaceutical industry and medical institutions. By understanding and mastering the basic concepts and applications of CNC precision manufacturing, we can better grasp the future development direction of the medical industry.

Technical Advantages of Manufacturing Precision Medical Components

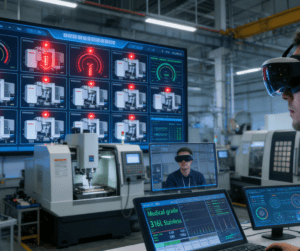

In the manufacturing process of precision medical components, CNC precision manufacturing demonstrates its high-precision machining capabilities. We can achieve micron-level machining accuracy through this technology, which is essential for meeting the stringent safety and reliability requirements of medical devices. This high precision not only ensures the functionality of components but also significantly reduces errors during assembly, enhancing the overall performance and stability of the equipment. Moreover, CNC technology can handle components of various complex shapes and materials, providing great support for the flexibility of our product design. For electronic components in precision medical devices (such as control circuit boards of diagnostic equipment), we also integrate Automatic placement machines with CNC precision manufacturing; these machines can achieve high-precision placement of tiny electronic components, working in synergy with CNC-machined structural components to ensure the overall precision and operational stability of medical equipment.

At the same time, rapid prototyping and iteration represent another important advantage of CNC precision manufacturing. We can produce product samples in a short time, which not only shortens the development cycle but also allows the design team to obtain feedback and make adjustments promptly. This flexibility enables medical devices to adapt to market demands more quickly during the launch process and enhance their competitiveness. Additionally, through repeated iterations, we can continuously optimize product designs and improve their clinical applicability, so as to better meet the needs of doctors and patients. Therefore, in the modern medical industry, CNC precision manufacturing technology is undoubtedly a driving force for our continuous progress.

The Importance of CNC Machining Centers in the Medical Industry

In the medical industry, CNC machining centers play an indispensable role. First and foremost, they provide us with high-precision machining capabilities, enabling medical precision components such as surgical instruments, implants, and various laboratory equipment to meet the most stringent quality standards. Such precision not only ensures the safety and effectiveness of products during use but also promotes the development of personalized medicine.

Second, the rapid prototyping capability of CNC machining centers allows us to iterate designs quickly and update them according to clinical needs, thereby shortening the R&D cycle and reducing costs. This is of great significance for the continuous advancement and innovation of medical technology.

Furthermore, the flexibility of CNC machining centers enables them to adapt to the processing needs of components made from different materials and with complex shapes, which is particularly important when dealing with diverse products. With continuous technological progress, CNC machining centers are gradually becoming an important tool for enhancing the competitiveness of the medical device industry.

How to Select Suitable CNC Precision Manufacturing Services

When it comes to selecting suitable CNC precision manufacturing services, we need to focus on several key factors. First, understanding the supplier’s technical strength is crucial. We need to evaluate the equipment and technologies they use to ensure that they have advanced CNC machining capabilities and can handle specific materials and complex designs. In addition, we can obtain genuine feedback from customers on their strength and service quality through market reputation and customer evaluation.

Second, service flexibility is equally important. We hope to find partners who can adjust production plans in a timely manner according to our needs, provide samples, and offer modification solutions. A good machining service provider should be able to respond quickly to changes in our requirements to meet the medical industry’s demand for rapid product iteration and market launch.

Finally, cost control cannot be ignored. On the premise of ensuring quality and efficiency, we need to compare multiple suppliers to find the most cost-effective solution. A comprehensive evaluation of these factors can help us select suitable and reliable CNC precision component processing services, providing strong support for our medical projects.

Current Development Trends and Future Outlook of CNC Technology

With the continuous advancement of science and technology, we have witnessed the gradual expansion of the application of CNC precision manufacturing technology in the medical field, along with several prominent development trends. First, the integration of intelligent technologies has made CNC machining processes more efficient and accurate. By combining artificial intelligence and machine learning, we have improved the automation level of equipment, significantly reduced human errors, and enhanced productivity.

Second, the growing demand for personalized medicine has driven CNC manufacturing technology towards greater flexibility and refinement. We can quickly customize medical components according to the needs of different patients, facilitating the implementation of personalized treatment plans. In addition, the application of advanced materials continues to broaden our horizons. In the production of medical devices, new high-performance materials such as biocompatible materials and lightweight alloys have significantly improved product performance.

Finally, we should pay attention to the major trend of sustainable development. A growing number of manufacturers are exploring green manufacturing, achieving environmental protection goals by optimizing processing procedures, reducing waste materials, and using recyclable materials. This is not only a requirement for industry development but also a social expectation for corporate responsibility. Against this backdrop, we are full of confidence in the future prospects of CNC precision manufacturing in medical components, as it will lead the industry towards higher levels of development.

Assembly line for mass production by artificial intelligence