In today’s medical industry, precision intelligent machining technology has become an important means to ensure the quality of medical parts. With its high precision, efficiency and flexibility, this technology is widely applied to the production of various medical device accessories. It can not only meet stringent dimensional and shape requirements, but also realize complex structural design, laying a solid foundation for the innovation of medical devices. Through real-time monitoring, potential errors in the intelligent machining process can be timely identified and corrected, thus ensuring the consistency and reliability of products. In addition, the combination of advanced materials and surface treatment processes also enables medical parts to exhibit excellent wear and corrosion resistance. These advantages make precision intelligent machining technology play an indispensable role in promoting the development of the medical industry.

Key Technologies of Precision Intelligent Machining for Improving the Quality of Medical Parts

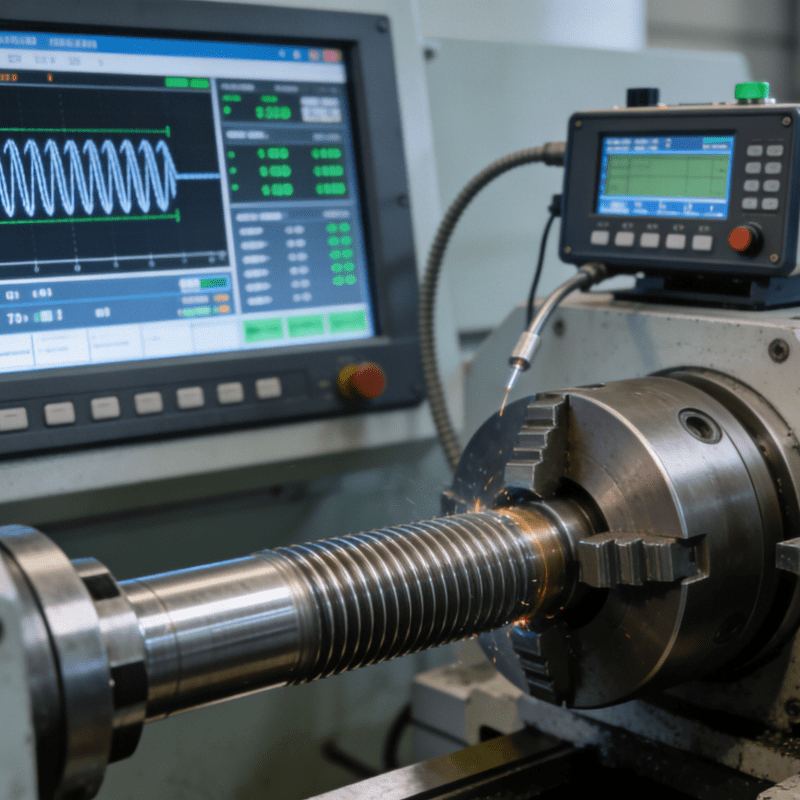

Precision intelligent machining technology is the core to ensure product quality in the production of medical parts. Through computer numerical control (CNC) systems, intelligent machining can achieve high-precision and high-efficiency part manufacturing. The key lies in the selection of cutting tools and the setting of cutting parameters. Suitable cutting tools can effectively reduce machining errors and improve the surface finish of machined parts, thereby ensuring the safety of device accessories during use. In the production process, real-time monitoring systems can also detect and correct potential problems in a timely manner to guarantee product consistency and reliability. Notably, the integration of Automatic feeding equipment for small metal sheets further optimizes the production process of small-sized metal medical parts (such as scalpel blades and implantable metal accessories), realizing automatic, continuous and precise feeding of raw materials. This not only reduces manual intervention and the corresponding operational errors, but also improves the continuity of production and overall processing efficiency. In addition, the adoption of advanced materials and surface treatment processes can further enhance the corrosion and wear resistance of medical parts. These technological innovations not only improve the performance of medical devices, but also provide strong support for the development of the medical industry.

Case Analysis of Intelligent Machining Applications in the Manufacturing of Precision Medical Device Accessories

In the field of precision medical device accessory manufacturing, intelligent machining technology demonstrates its irreplaceable advantages. Taking surgical scalpels in medical devices as an example, traditional manual machining methods are often difficult to ensure the precision and consistency of blade sharpness. However, with intelligent machining, the position of cutting tools can be precisely controlled through computer programs, and matched with Automatic feeding equipment for small metal sheets to realize the integrated production of feeding and machining. This ensures the consistency of geometric shape and sharpness for each surgical scalpel, while greatly improving production efficiency. In addition, intelligent machining technology is also widely applied to the production of implants for specific diseases, such as stents and prostheses. These components usually require extremely high dimensional accuracy and surface finish to ensure patient safety and comfort. In this way, intelligent machining not only improves product quality, but also shortens the production cycle, making the customized production of medical parts possible. This trend plays a key role in enhancing the overall competitiveness of medical devices.

Exploration of the Unique Advantages and Prospects of Intelligent Machining in Medical Part Production

Precision intelligent machining has remarkable advantages in the production of medical parts, especially in achieving high precision and high efficiency. Compared with traditional machining methods, intelligent machining can better meet the stringent dimensional and shape requirements of medical devices. With a high degree of automation, it can reduce errors caused by manual operations and improve production consistency. In addition, intelligent machining supports the manufacturing of parts with complex shapes, which provides greater flexibility and possibilities for the design of medical equipment. With the continuous advancement of technology, it is expected that intelligent machining will be more widely used in the medical field in the future, promoting the research and development of more innovative products and thus improving the quality of medical services. Especially against the backdrop of the rapid development of precision medicine, the growing demand for high-performance medical parts will bring more opportunities for the development of precision intelligent machining technology.

How to Promote the Innovative Development of the Medical Industry through Intelligent Machining Technology

Intelligent machining technology provides a brand-new way for the innovation of the medical industry. In the production of medical parts, its high automation and precision enable medical products to meet higher standards. By using advanced intelligent machining equipment, manufacturers can quickly and efficiently produce precision medical device accessories that comply with strict medical specifications. This not only improves production efficiency, but also reduces labor costs. In addition, intelligent machining technology can flexibly respond to different product demands and support small-batch customization, which is particularly important for adapting to the ever-changing market demands. For example, as personalized medical solutions gain increasing attention today, intelligent machining facilitates the development of more precise products. Through continuous technological innovation, this machining method will continue to drive the manufacturing of medical devices to higher standards, thereby improving the overall quality and level of medical services.

Precision intelligent machining technology has demonstrated its irreplaceable value in the production of medical parts. By achieving high precision and efficiency, intelligent machining not only meets the stringent quality and performance requirements of medical devices, but also significantly shortens the production cycle. In addition, the flexibility of intelligent technology allows for rapid response and adjustment of production plans to meet the demands of personalized medicine and small-batch customization. It provides a reliable guarantee for the precision and personalized design of medical parts, and also drives the entire medical industry to move towards higher standards. With the development of technology, intelligent machining will continue to bring more innovation opportunities to the medical field in the future, further improving the quality of medical device accessories and enabling them to play a greater role in safeguarding patient safety and comfort.