From Robotic Arms to Smart Factories: The Technology Transforming Modern Manufacturing

Automatic assembly refers to the use of mechanized and automated equipment to perform various functions in an assembly line or unit. An automatic assembly system carries out a series of automated operations to combine multiple components into a single entity, which can be either a final product or a sub-assembly. It also provides a systematic method for assembling goods that can be completed at least partially without human intervention.

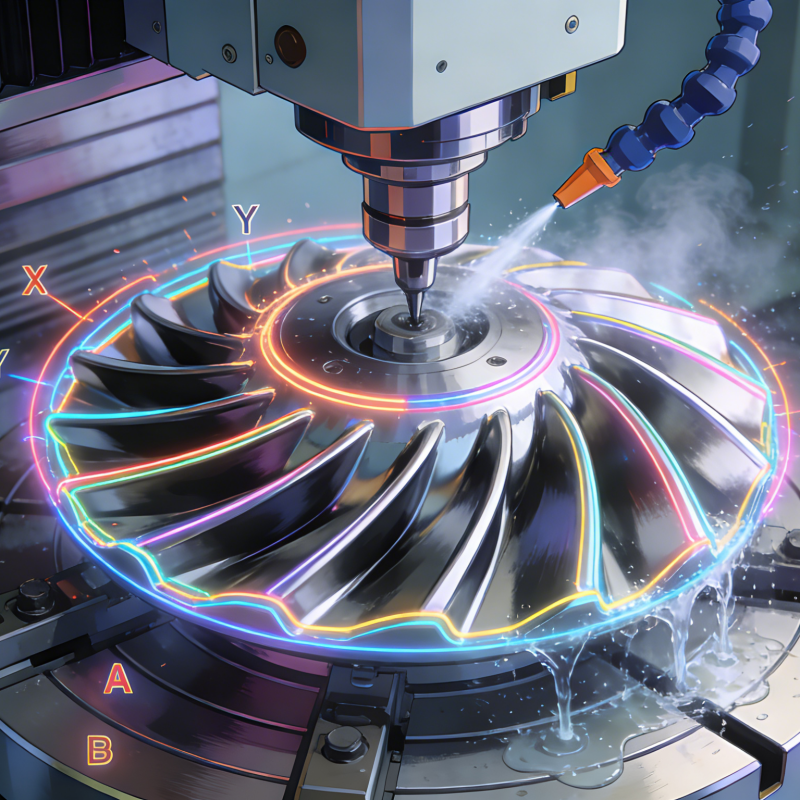

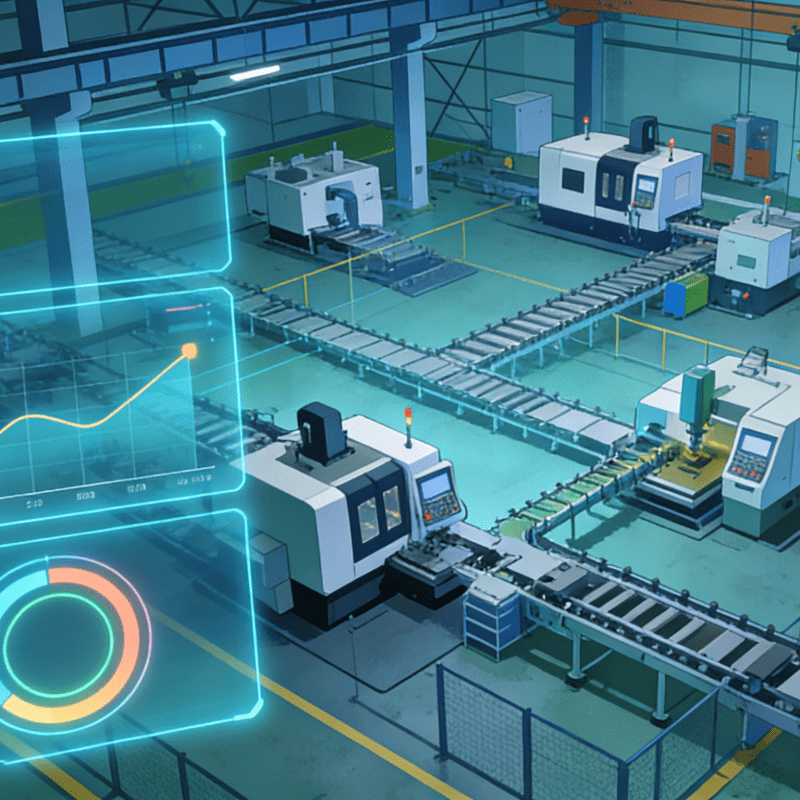

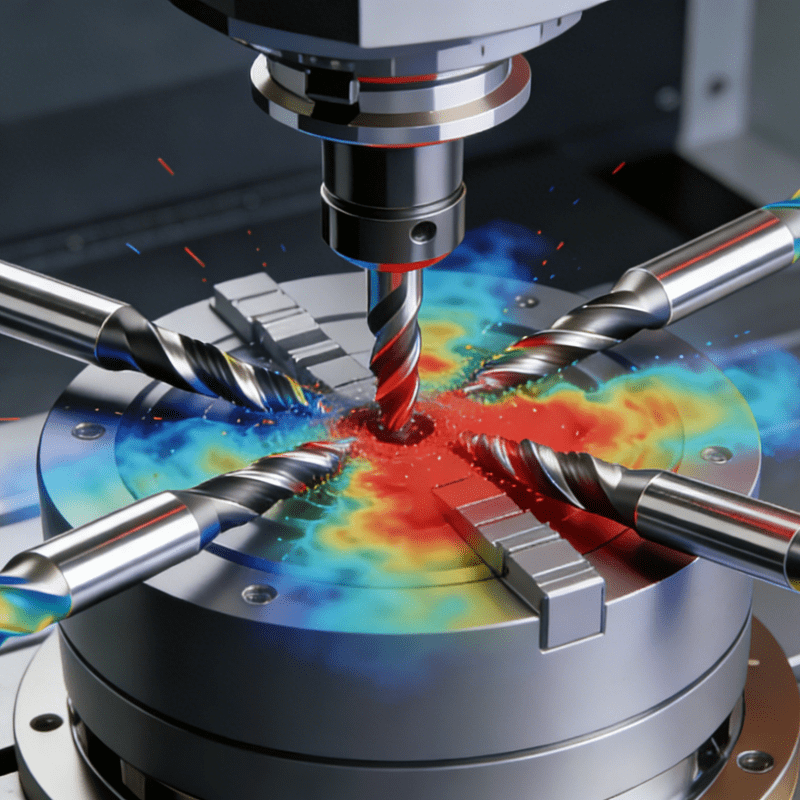

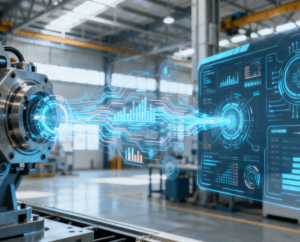

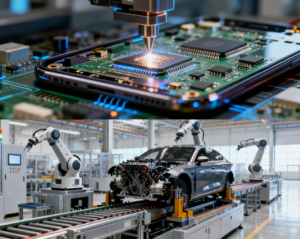

In the current era of global smart manufacturing, efficiency, precision, and large-scale production have become the keys to enterprise competitiveness. The automatic assembly system is the core technology supporting this goal—it is not simply “robots replacing humans,” but an integrated solution combining mechanical, electronic, software, and sensing technologies. It can automatically complete the entire process from part delivery, positioning, assembly to inspection, completely transforming the limitations of traditional manual assembly. From the soldering of mobile phone chips to the assembly of automobile engines, automatic assembly systems have become the “standard configuration” of modern factories. So, what exactly is it? How does it work? And why can it reshape manufacturing? This article will comprehensively break down this “workhorse” of smart manufacturing.

Automatic Assembly Systems: More Than Just “Machines Replacing Humans”

From definition to application, the core value of automatic assembly systems goes far beyond “replacing humans”—it is the key carrier for the transformation of manufacturing from “traditional mass production” to “intelligent precision production.” By integrating mechanical, electronic, software, and data technologies, it solves the triangular challenge of efficiency, precision, and cost, while providing enterprises with the flexibility to respond to market demands for “multiple varieties and small batches.”

In the future, with the integration of technologies such as AI and digital twins, automatic assembly systems will become more “intelligent” and “flexible,” serving as the “core engine” of smart manufacturing. For enterprises, embracing this technology is not only a choice to increase production capacity, but also a necessity to gain a firm foothold in global competition.