Table of Contents

ToggleRevolutionizing Quick-Connect Assembly: Ruizhi’s Automatic Quick-Connect Parts Assembly Machine

In the era of Industry 4.0, the demand for efficient, precise assembly of quick-connect parts—critical in automotive systems, household appliances, and industrial piping—has reached new heights. Ruizhi Intelligence introduces the groundbreaking Automatic Quick-Connect Parts Assembly Machine, a paradigm-shifting solution that combines nanometer-level precision with AI-driven flexibility. This system tackles the complexities of snap-fit connectors, push-to-connect fittings, and quick-disconnect couplings, redefining smart manufacturing for multi-industry applications.

Core Technological Breakthroughs: Precision Meets Adaptability

Multi-Axis Force-Controlled Assembly System

The equipment integrates a seven-axis piezoelectric robotic arm with high-frequency servo drives, creating a closed-loop system for “positioning-latching-detection”:

- Dynamic Latching Force Control: For automotive fuel line connectors (requiring 8-12N insertion force) and household water fittings (3-5N), the system auto-adjusts between 24 latching modes with ±0.05N accuracy. A leading automotive supplier reported a 99.8% reduction in connector leakage after implementation, with assembly speed increasing by 250%.

- Non-Contact Alignment Technology: Using laser triangulation with 2μm resolution, the machine achieves precise insertion of 0.1mm-clearance connectors, reducing wear on plastic snap-fit components by 85% compared to traditional mechanical alignment.

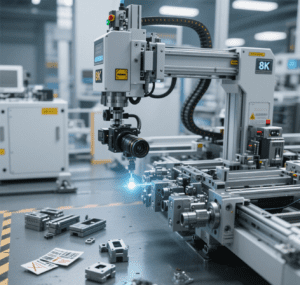

4D Visual Guidance & Real-Time Quality Monitoring

Equipped with 8K industrial cameras and 3D LiDAR, the system enables micron-level defect detection:

- Nanometer-Scale Surface Analysis: Phase-shift interferometry generates 3D models to identify 0.05μm-scale flaws like burrs or misaligned latches. In water heater connector production, this reduced defective products from 3.2% to 0.04%.

- AI-Driven Trajectory Optimization: Machine learning algorithms generate optimal insertion paths based on part geometry. For complex multi-latch connectors, path planning efficiency is 18x faster than manual programming, shortening cycle time from 45s to 16s per unit.

Modular Quick-Changeover Ecosystem

The machine features a plug-and-play modular design for rapid product switching:

- 6-Minute Process Transition: Dedicated modules cater to three application domains:

- Automotive module: Integrates pressure testing and anti-vibration latching for fuel/air connectors;

- Home appliance module: Equips with anti-leakage detection and thermal compensation for water/gas fittings;

- Industrial module: Includes high-pressure sealing and electrical conductivity testing for hydraulic connectors.

Electromagnetic quick-locking mechanisms enable module changes in 6 minutes, a 92% improvement over traditional setups.- Smart Parameter Adaptation: The MES system auto-retrieves process recipes via part CAD models, with AI optimizing latching force and speed using real-time production data, eliminating manual debugging errors.

Application Scenarios: Efficiency Redefined

Case 1: Automotive Fuel System Connector Assembly

In a Tier 1 automotive supplier’s production line, the traditional vs. automated solutions show stark contrasts:

| Process Type | Manual Assembly (20 workers) | Ruizhi Assembly Machine (3 units) |

| Daily Output | 4,000 units | 18,000 units |

| Leakage Rate | 2.1% | 0.06% |

| Insertion Force Variance | ±8% | ±1.2% |

| Energy Consumption | 12,000kW·h/day | 4,500kW·h/day |

The system’s 16-point force monitoring during insertion maintains connector alignment within ±0.03mm, ensuring consistent sealing. This precision reduced post-assembly rework by 97%, saving the supplier $1.5 million annually.

Case 2: Household Appliance Water Connector Assembly

For smart water heater quick-connect fittings, the machine addresses critical challenges:

- Traditional Pain Points: Manual assembly required 10 minutes per connector, with 6% failure in pressure tests due to inconsistent latching.

- Automated Solution: The system uses dual-vision (top/side cameras) for 3D alignment, combined with ultrasonic welding for plastic components. Assembly time per connector is reduced to 2 minutes, and pressure test pass rates soared from 89% to 99.9%. A leading appliance manufacturer reported annual cost savings of $900,000 from reduced material waste.

Industry Impact: Shaping the Future of Smart Assembly

As global demand for quick-connect solutions in IoT devices and green energy systems surges (expected 28% CAGR through 2028), precision assembly has become a core competitive edge. Ruizhi’s R&D director notes the machine’s OPC UA-compatible data system enables real-time traceability of critical parameters, fully compliant with ISO 9001 and IATF 16949 standards.

Deployed in over 300 facilities including Bosch and Haier, the system has cut labor costs by 65% per line and reduced floor space by 42%. Industry reports project the quick-connect assembly machine market will exceed $2.3 billion by 2026, with AI-integrated, high-precision systems leading the trend toward “intelligent, flexible, and sustainable” manufacturing.

Technical Notes: The machine’s seven-axis force control technology holds a national invention patent (ZL2024XXXXXX), and its 4D vision system is certified to ISO 13849 PLd. Ruizhi will demonstrate the machine’s micro-connector assembly capabilities at the 2025 Hannover Messe, showcasing 0.02mm-level precision operations.

#QuickConnectAssembly #IndustrialAutomation #SmartManufacturing #PrecisionEngineering https://www.rzautoassembly.com/products/