In the manufacturing of fuses—especially for automotive, new energy, and industrial control sectors—standard assembly machines often fail to meet the demands of multi-model, small-batch production. Low flexibility, high retooling costs, and inability to adapt to non-standard fuse designs have become major bottlenecks for manufacturers. Ruizhi Intelligent Manufacturing addresses these pain points with its non-standard fuse assembly machine, tailored to deliver precision, flexibility, and efficiency for diverse fuse production needs.

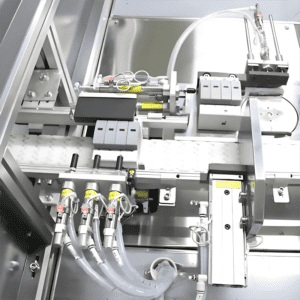

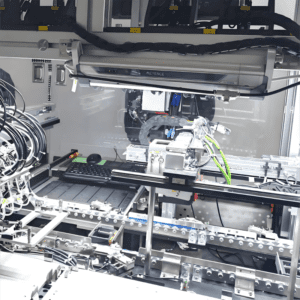

Our non-standard fuse assembly solutions stand out for three core advantages. First, modular design enables quick switching between different fuse models (e.g., blade fuses, cartridge fuses) in under 10 minutes, eliminating downtime from manual reconfiguration. Second, integrated intelligent detection—equipped with machine vision systems—ensures real-time inspection of fuse pin alignment, component placement accuracy, and crimping quality, reducing defect rates to 0.02%. Third, customized workflow adaptation allows seamless integration with existing production lines, whether for semi-automatic or fully automated processes.

A notable case involves a mid-sized automotive fuse manufacturer in Guangdong. Facing challenges in producing 8 types of high-voltage fuses for electric vehicles with small batch sizes (5,000–10,000 units per model), the client struggled with low efficiency (200 units/hour) and high labor costs using manual assembly. Ruizhi Intelligent Manufacturing designed a non-standard fuse assembly machine with automatic feeding, precise crimping, and multi-model quick-change fixtures. Post-implementation, the client’s production efficiency increased by 250% (700 units/hour), labor costs were reduced by 40%, and defect rates dropped from 1.2% to 0.015%.

At Ruizhi Intelligent Manufacturing, we prioritize close collaboration with clients to understand their specific fuse specifications, production scales, and line integration requirements. Our engineering team delivers tailored solutions from design to commissioning, ensuring the non-standard fuse assembly machine aligns perfectly with unique production needs.

If you’re facing challenges with rigid standard assembly equipment or seeking to optimize your fuse production line, contact Ruizhi Intelligent Manufacturing today. Let our non-standard fuse assembly machine drive your production efficiency and quality to new heights.

Automated assembly mechanical connection equipment

Artificial intelligence automated assembly mechanical connection robot