Cracking the Dilemma of Small-Batch Multi-Variety Production: Three Breakthrough Points of Flexible Automatic Assembly Equipment

Įvadas

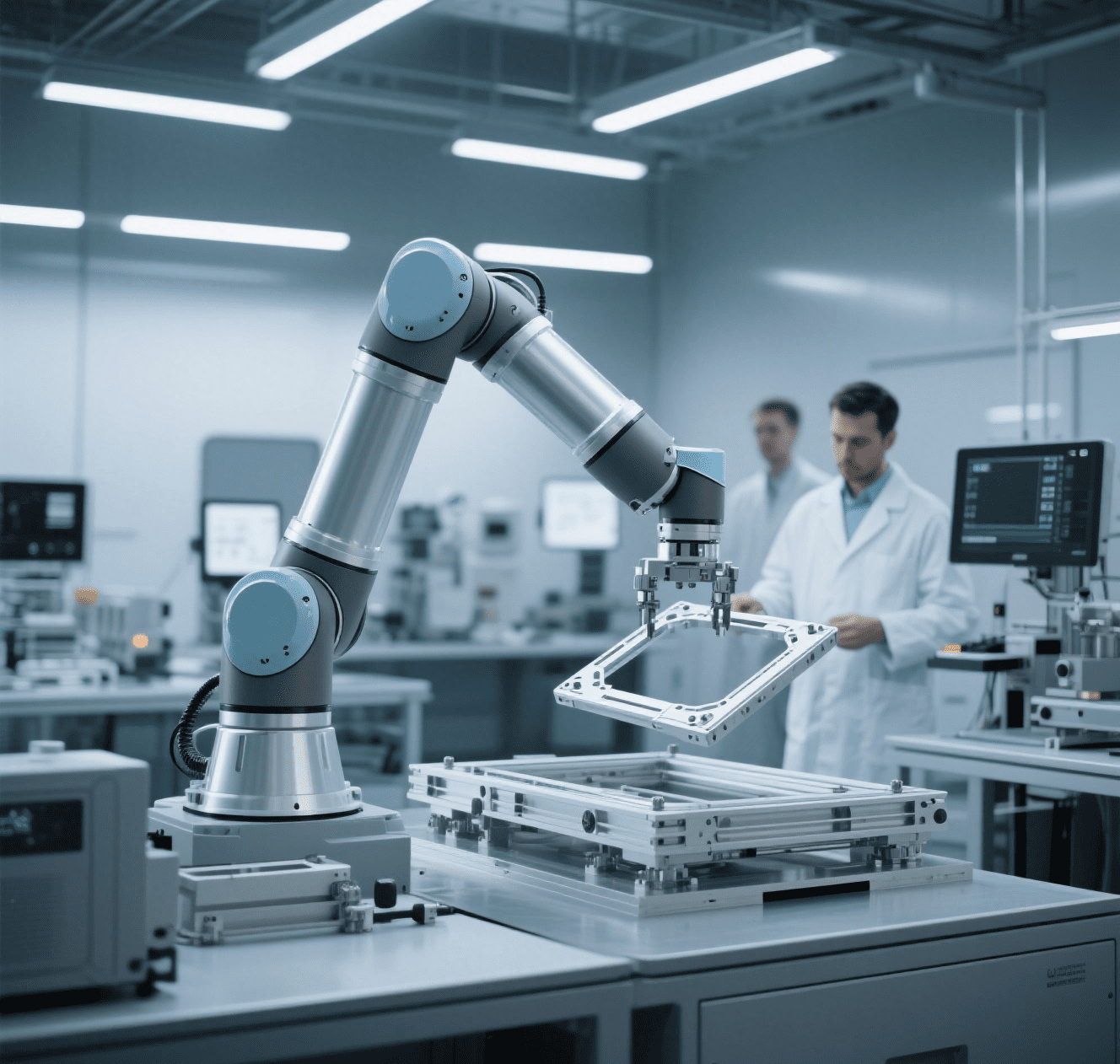

As “personalized customization” becomes the new normal in manufacturing, the “economies of scale” advantage of traditional assembly lines fails in the face of market demands for “minimum order quantities of 500 pieces”. Small and medium-sized enterprises generally face three pain points: high model switching costs (accounting for 35% of production costs), low capacity utilization (average below 60%), and large quality fluctuations (defect rate exceeding 5%). Flexible automatic assembly equipment reconstructs production logic through technological innovation, transforming “multi-variety small-batch” production from “losing money for market share” to “profitable business”. Combining practical experience in automotive parts, medical devices, and small home appliances industries, this article analyzes the technical paths and value transformation of the three core breakthrough points.

I. Breakthrough Point 1: The Cost Paradox — Reconstructing the Economic Model from “Fixed Investment” to “Elastic Manufacturing”

1. “Lightweight” Design of Hardware Costs

Generalized Fixture Technology:

Develop pneumatic adaptive grippers (clamping force range 0.5-20N, compatible with workpiece sizes 5-100mm), achieving wrap-around grabbing of irregular objects (such as curved bathroom fittings) through shape memory alloy springs. The fixture general utilization rate increases from 40% to 85%. A domestic bathroom enterprise thus reduces fixture inventory by 60%, saving 1.2 million yuan annually.

Distributed Control Architecture:

Adopt a lightweight control solution of “PLC + edge computing” (hardware costs reduced by 30%), supporting drag-and-drop configuration of new model parameters through the HMI interface (e.g., on a coffee machine assembly line, non-professionals can complete parameter settings within 30 minutes), avoiding the high labor costs of traditional production lines dependent on professional engineers.

2. “Skill Upgrading” of Labor Costs

Reconstruction of Human-Machine Collaboration Positions:

In precision bearing assembly, robotic arms undertake pressing tasks with an accuracy of ±0.01mm, while workers focus on incoming material appearance inspection and exception handling. Manpower requirements per workstation are reduced from 3 to 1, and real-time operation guidance is obtained through AR glasses (training cycle shortened from 2 weeks to 2 hours). A German-funded bearing factory achieves a 40% reduction in labor costs and a 35% increase in employee satisfaction.

“Predictive” Transformation of Equipment Operation and Maintenance:

Deploy a vibration analysis system (sampling frequency 10kHz) to early warn of robotic arm joint wear (accuracy 92%), transforming passive maintenance (average downtime 4 hours/time) into preventive maintenance (downtime ≤30 minutes/time). A Japanese motor factory reduces annual downtime losses by 2 million yuan.

II. Breakthrough Point 2: Efficiency Bottleneck — Process Reengineering from “Linear Production” to “Parallel Intelligence”

1. “Digital Twin” Scheduling for Mixed-Line Production

Application of Real-Time Simulation Technology:

Construct a digital twin of the production line in Siemens Plant Simulation. After inputting multi-product BOM data, it automatically identifies process conflict points (such as fixture usage priority and robotic arm movement path interference). A new energy vehicle parts factory reduces the beat loss of multi-model collinear production from 25% to 8% through simulating over 100 production scenarios, increasing capacity by 22%.

Breakthrough in Dynamic Scheduling Algorithms:

Develop an ant colony optimization-based order allocation model to prioritize matching orders with process similarity ≥70% (e.g., the wire welding process sharing rate between mobile phone chargers and headphones reaches 85%). A 3C foundry thus shortens order switching time from 2 hours to 30 minutes, increasing equipment utilization from 65% to 88%.

2. “Full-Link” Optimization for Rapid Model Switching

Rapid Switching at the Physical Layer:

Adopt electromagnetic quick-change devices (model switching time ≤10 seconds, repeat positioning accuracy ±0.02mm), combined with an automatic tool setting system (laser rangefinder accuracy ±0.01mm). A hardware products factory compresses the replacement time of stamping dies from 60 minutes to 5 minutes, achieving mixed production of 20 hardware parts.

Parameter Reuse at the Software Layer:

Establish a “product gene library” to store process parameters of over 200 models (such as tightening torque, positioning coordinates, and detection thresholds). When invoked, AI algorithms automatically compensate for incoming material differences (e.g., when the dimensional tolerance of plastic parts is ±0.3mm, the fixture clamping position is automatically adjusted by ±0.2mm). A small home appliance factory thus shortens the first-piece debugging time by 70%.

III. Breakthrough Point 3: Quality Fluctuation — Quality Revolution from “Experience Control” to “Data Closed Loop”

1. Full-Process Quality Traceability System

Digital Twin Quality Modeling:

Construct a multi-variable quality model in Minitab, associating the mapping relationship between over 200 process parameters (such as pressure, temperature, and time) and yield. A medical device factory controls the key parameter fluctuations in surgical scissors assembly within ±1% through model prediction, reducing the defect rate from 4.2% to 0.6%.

Upgrading of Real-Time Detection Technology:

Deploy linear array cameras (resolution 12K) and 3D laser scanners (accuracy ±5μm) to achieve closed-loop control of “incoming material inspection – process monitoring – finished product full inspection” in connector assembly. A Taiwan-funded electronics factory reduces the missed detection rate of dimensional overrun from 0.8% to 0.05%, with customer complaints decreasing by 90%.

2. Adaptive Quality Control Algorithms

SPC Real-Time Feedback Mechanism:

Trigger an SPC process capability analysis (calculating CPK value) for every 50 products. When CPK < 1.33 is detected, the equipment automatically adjusts the pressing pressure by ±5%. An automotive sensor factory increases the process capability index from 1.1 to 1.67, reducing quality costs by 65%.

Vision-Guided Error-Proofing System:

Adopt deep learning algorithms to identify over 100 types of assembly defects (such as missing assembly, wrong assembly, and reverse assembly), with a detection speed ≤0.2 seconds/piece and accuracy of 99.8%. The intelligent toilet seat assembly line of a German home appliance factory reduces functional failures by 85% through this system, saving 1.5 million yuan/year in after-sales maintenance costs.

IV. Industry Practice: Value Breakthrough Paths for Small-Batch Production

1. Automotive Parts: Addressing High-Frequency Model Switching Demands of “New Four Modernizations”

Case: OBC Controller Assembly of a Domestic New Energy Vehicle Enterprise:

Facing over 10 new orders monthly (minimum batch 200 pieces), flexible equipment achieves “2-hour model switching, 30-minute first-piece verification”, increasing efficiency by 3 times compared to traditional production lines (4-hour model switching + 2-hour first-piece debugging). It successfully enters the international Tier 1 supply chain, with orders increasing by 40% annually.

2. Medical Devices: Meeting “Multi-Specification” Compliance Production Requirements

Practice: Insulin Pen Assembly of a US-Funded Enterprise:

Develop “multi-standard process packages” (compatible with FDA, CE, ISO 13485). The equipment automatically switches data recording precision (FDA mode records to 1μs-level timestamps, CE mode simplifies to 1ms). In the mixed production of 10 specifications of insulin pens, the compliance audit time is shortened from 4 weeks to 3 days, with capacity increased by 25%.

3. Small Home Appliances: Cracking the Cost Dilemma of “Personalization”

Implementation: Flexible Line for Air Fryers of a Domestic Brand:

Through generalized heating component assembly modules (compatible with 3L/5L/8L capacities) and adaptive appearance detection modules (identifying over 100 colors and textures), it realizes the C2M model of “production upon order placement”. The minimum order quantity is reduced from 5,000 pieces to 50 pieces, with production costs increasing by only 8%, successfully capturing the online celebrity small home appliance market.

V. Future Directions: Intelligent Upgrading of Small-Batch Production

1.Application of Digital Thread Technology: Through the ISO 10303 standard, integrate product design – process planning – production execution to achieve “zero-drawing” introduction of new products (a Swiss watch enterprise shortens new product R&D cycle by 40%).

2.Reinforcement Learning Scheduling System: Enable equipment to autonomously optimize scheduling strategies. A pilot project in a German factory shows that capacity utilization for multi-variety production can be increased to 92%, 15% higher than traditional algorithms.

3.Edge AI Quality Prediction: Deploy lightweight neural networks at the device end (model size <10MB) to achieve real-time defect prediction (response time ≤10ms), thus tripling the online quality control capability of an electronics factory.

Conclusion

The breakthrough in small-batch multi-variety production essentially redefines the “manufacturing logic” — no longer pursuing the ultimate efficiency of a single product, but building a “rapid response” capability system. Flexible automatic assembly equipment transforms “variety switching” from a “cost burden” to “value creation” through three paths: hardware elasticity, process intelligence, and quality dataization. For small and medium-sized enterprises, this is not only equipment upgrading but also business model reconstruction: when production lines can produce small batches at costs close to large batches and meet personalized needs with precision exceeding special machine lines, they can establish a “fast-track” core competitiveness in niche markets. In the future where “everything can be customized”, only manufacturing systems with flexible genes can win the right to survive in the balance between “scale” and “personality” — this is the ultimate answer of flexible equipment to crack the small-batch dilemma.

#Flexible Manufacturing #Small-Batch Multi-Variety Production #Elastic Manufacturing