Table of Contents

ToggleChangAn Unveils Rayong Factory: Pioneering Sustainable Automotive Automation in Southeast Asia

In a landmark move for the automotive industry, ChangAn Automobile has launched its first international new energy vehicle (NEV) manufacturing base in Rayong, Thailand, showcasing cutting-edge automotive automation and automated equipment designed to redefine sustainable manufacturing. The factory’s opening, coinciding with ChangAn’s 28.59 millionth vehicle rolling off the line, marks a pivotal step in the company’s global expansion—and a testament to how advanced automation is driving efficiency, cost-effectiveness, and quality in automotive production.

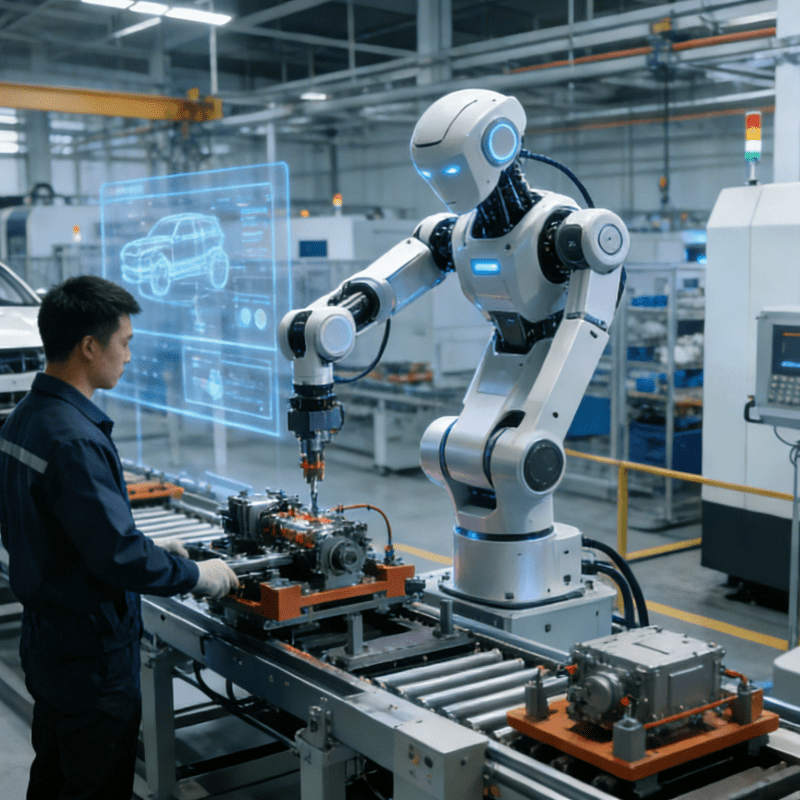

“ChangAn’s Rayong Factory embodies the future of the automotive industry: a fusion of green technology, intelligent systems, and automated precision,” said Shen Xinghua, Managing Director of ChangAn Automobile Southeast Asia Business Unit. “By integrating 90% automation at key quality control stations and leveraging state-of-the-art robotic systems, we’re not just building vehicles—we’re setting a new standard for sustainable manufacturing in Thailand and beyond.”

A Hub of Automotive Automation and Sustainable Innovation

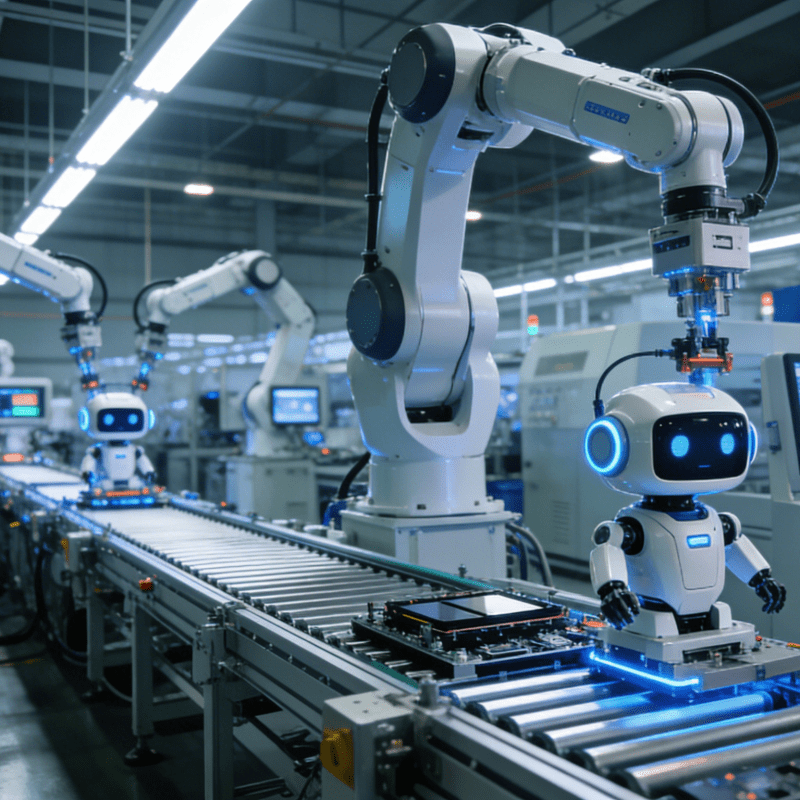

As a cornerstone of ChangAn’s Vast Ocean Plan, the Rayong Factory transitions the company from product exports to full-scale industrial globalization. The facility’s five intelligent workshops—welding, painting, general assembly, engine assembly, and battery—are powered by automated equipment that rivals the best in the automotive industry:

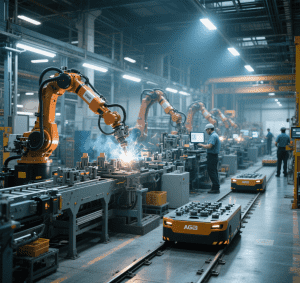

- Welding Workshop: 39 robots employ advanced joining techniques (FDS, EPS, SPR) to create vehicle structures stronger than traditional methods, ensuring durability and safety.

- Painting Workshop: 29 robots use precision spraying to extend paint life to 15 years while reducing emissions by 40%, aligning with Thailand’s green manufacturing goals.

- Assembly Line: 140 stations (18 fully automated, 125 semi-automated) with AGV vehicles enable flexible, multi-model production, including NEVs and internal combustion engine (ICE) cars.

- Power Workshop: Ultra-precise engine tile-matching and 22-step battery production with visual guidance ensure high-performance powertrains, supported by 45 AGVs for agile material transport.

“Sustainability and automation go hand in hand here,” added Xinghua. “Our 14MW photovoltaic system supplies 45% of the factory’s electricity, while rainwater recycling and energy-efficient ventilation cut costs by 5%. This is how the automotive industry balances innovation with environmental responsibility.”

Digital Integration and Operational Excellence

The Rayong Factory stands out as a “digital-first” facility, leveraging a full-stack digital ecosystem with microservice architecture for 100% online operations. Real-time scheduling optimizes supply chain coordination, reducing order delivery cycles from 21 to 15 days—a breakthrough in automotive efficiency.

Quality control is embedded at every stage via the ChangAn Quality Operating System (CAQOS), which uses 77 surveillance cameras, 62 foolproof checkpoints, and 71 quality containment processes. This ensures that every vehicle meets global standards, from supplier parts to final assembly— a testament to how automated equipment and AI-driven systems are elevating manufacturing precision.

“Digitalization isn’t just about speed; it’s about consistency,” said Dr. Li Wei, ChangAn’s Chief Automation Engineer. “Our robotic systems and real-time data analytics eliminate human error, ensuring that each vehicle leaving Rayong is a model of reliability—whether it’s bound for Thailand’s roads or exported to Southeast Asia, Australia, or New Zealand.”

Closing: Driving the Automotive Industry’s Low-Carbon, Automated Future

With plans to localize 80% of production, create 30,000 jobs, and launch 12 new energy models over three years, ChangAn’s Rayong Factory is more than a manufacturing hub—it’s a catalyst for Thailand’s automotive transformation. By prioritizing automotive automation and sustainable practices, the facility aligns with the global industry’s shift toward electrification and intelligent manufacturing.

“ChangAn’s commitment to ‘In Thailand, For Thailand, and For the World’ reflects our belief that advanced automation and green technology can coexist,” concluded Xinghua. “As we scale production, we’re not just contributing to Thailand’s economy—we’re proving that the automotive industry can drive growth while reducing its carbon footprint. The Rayong Factory is a blueprint for what’s possible when innovation meets purpose.”

For the automotive industry, ChangAn’s latest milestone serves as a rallying cry: the future belongs to those who embrace automation, sustainability, and global collaboration. With Rayong as its Southeast Asian anchor, ChangAn is poised to lead this charge, ensuring that every vehicle it produces is a symbol of efficiency, quality, and a cleaner tomorrow.