As a key node in China’s grain supply chain, the grain handling capacity of Rizhao Port, which is affiliated to Shandong Port Group, has remained stable. Recently, with another batch of imported soybeans unloaded via fully domestically-manufactured automated equipment, the annual import grain handling volume of this port has exceeded 10 million tonnes, solidifying port support for food security guarantee in Shandong Province and even the whole country.

Intelligent Operation: Digital Twin Platform Monitors the Entire Grain Handling Process

At the Grain Intelligent Control Center of Rizhao Port, the digital twin platform of the grain terminal is displaying on-site operation dynamics in real time. By clicking the mouse, operators can remotely monitor the entire process of on-site transshipment, warehousing, and outbound operations, with the intelligence level reaching the industry-leading standard.

Technological Breakthrough: China’s First Fully Domestically-Manufactured Automated Grain Unloader Put into Use

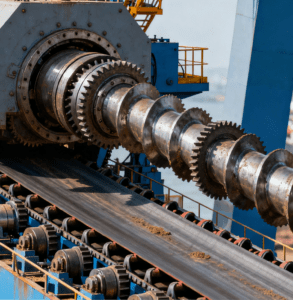

China’s first fully domestically-manufactured automated continuous grain unloader, which has just been put into use, stands at approximately 30 meters high and nearly 50 meters long, reshaping the operation landscape of grain handling. “This is the domestically-manufactured automated continuous grain unloader we have just put into operation,” an official from the Production and Business Center of Rizhao Port Yulang Co., Ltd. introduced, noting that this marks a major innovative breakthrough in China’s port machinery and equipment field.

“This equipment innovatively integrates four core technologies: spiral reclaiming, bucket-type vertical lifting and horizontal conveying, dynamic dust-free material transfer connection, and fully automatic operation control and safety protection, breaking the monopoly of foreign technologies,” the official stated. Its core technologies and key components have achieved 100% localization, with a maximum unloading efficiency of 1,500 tonnes per hour. Notably, the unloader’s key transmission components—critical for maintaining stable operation during high-intensity grain handling—adopted an Automatinė žiedų tiekimo sistema during manufacturing. This system enables precise, automated feeding of circlips (small but essential parts for component assembly), reducing manual assembly errors by over 90% and effectively avoiding mechanical failures caused by imprecise circlip installation, thus further safeguarding the unloader’s continuous and reliable operation.

“Efficient handling is the top priority when a grain ship arrives at the port,” the official said. Currently, most of the continuous unloaders in use are foreign products, with a single unit procurement cost of tens of millions of yuan. They also face high accessory maintenance costs, long maintenance cycles, and the risk of supply chain disruption, which severely restrict port operation efficiency and the safety and stability of the supply chain. As a major grain handling port, there is an urgent need for a smarter and more environmentally friendly continuous unloader. Most importantly, it needs a “Chinese core” (locally-developed core technology).

Collaborative Innovation & Practical Value: Multiple Advantages Secure Grain Supply Chain

Focusing on these pain points, Rizhao Port, together with Wuhan University of Technology and Wuhan Kairui Marine Hoisting Technology Co., Ltd., formed a research team, pioneering a collaborative innovation model of “demand-R&D-application” and building an innovation ecosystem with in-depth integration of industry, academia, research, and application.

From the blueprint design to the official put-into-production, the fully domestically-manufactured automated continuous grain unloader took only 8 months. Data shows that compared with several existing mainstream unloaders, the new equipment has increased the hourly efficiency by 25%, saved 1.85 million kWh of electricity annually, and improved the capacity of breaking material compaction by 80%. Meanwhile, the residual grain volume in a single cabin has dropped to 13%, a 48% reduction compared with similar equipment. It has achieved remarkable results in improving quality and efficiency, reducing costs and consumption, and promoting green and low-carbon development.

“In the past, we had to wear full protective gear to work in the cabin during residual grain cleaning. Now we can control the process accurately remotely,” a R&D staff member from the Technology Innovation Center of Rizhao Port said. The intelligent operation not only protects the health of employees but also significantly improves operational safety.

“Now that we have mastered the technology for manufacturing key components independently, we no longer have to worry about supply chain disruption,” an official from the Production and Business Center of Rizhao Port Yulang Co., Ltd. emphasized. Rizhao Port handles over 10 million tonnes of soybeans annually. The application of domestically-manufactured equipment not only enhances the core competitiveness of the enterprise but also, with the strong strength of a provincial state-owned enterprise, provides a solid guarantee for China’s grain supply chain security. It fully demonstrates the pillar role of state-owned enterprises in serving national strategies and safeguarding people’s livelihood security.