In the manufacturing of medical equipment spare parts, components such as joint holes of surgical instruments and sensor mounting holes of diagnostic equipment have extremely high requirements for hole precision and consistency — an error of just a few microns in these holes may affect the performance of the instruments and even patient safety. Spare parts of laboratory instruments in the life science field, such as pipeline interfaces of bioreactors and rotor holes of centrifuges, also require stable hole machining quality to ensure the accuracy of fluid transmission or high-speed operation.

However, traditional ordinary drilling machine processing methods often face problems such as insufficient precision, large repeated machining errors, and difficulty in achieving complex hole systems. The uncertainty of manual operation will also lead to uneven quality of workpieces in the same batch, which fails to meet the strict standards of the medical and life science fields. How to break through these machining bottlenecks and achieve high-precision and high-consistency hole machining? The emergence of drilling and boring technology provides an effective solution to this common industry problem.

Basic Concept and Technical Principle of Drilling and Boring Technology

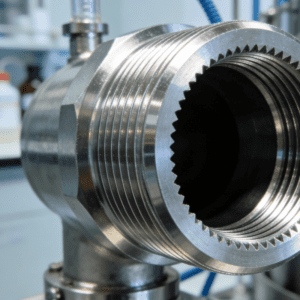

Drilling and boring technology is a precision machining process integrated with digital control technology. It accurately regulates the machine tool’s motion trajectory, tool parameters, machining rhythm and other aspects through computer programs to realize the integrated completion of drilling and boring processes. Its technical principle is based on the system’s instruction parsing capability, which converts the hole system information on the design drawings into motion paths recognizable by the machine tool, drives the coordinated movement of the spindle and the worktable, and ensures that the machining position, depth, diameter and other parameters of the tool on the workpiece fully meet the design requirements.

Different from traditional manual or semi-automatic machining, this process eliminates human operation errors, improves machining accuracy and stability through digital control, and is suitable for the machining needs of various complex hole systems.

Core Advantages of Drilling and Boring Technology Compared with Traditional Machining

Traditional hole machining usually requires the separate use of drilling machines and boring machines, with cumbersome processes and prone to positioning errors due to repeated clamping. Drilling and boring technology has obvious advantages: first, higher machining precision, which can achieve micron-level size control to meet the stringent precision requirements of medical equipment spare parts; second, improved machining efficiency, the integrated process reduces the time of workpiece handling and clamping, and the automatic feeding function optimizes the machining rhythm; third, strong capability in machining complex hole systems, which can complete tasks that are difficult for traditional processes such as inclined holes and deep holes; finally, good machining consistency, with minimal quality deviation of workpieces in the same batch, meeting the needs of large-scale production.

Key Application Scenarios of Drilling and Boring Technology

The core application scenarios of drilling and boring technology include the manufacturing of medical equipment spare parts and life science spare parts. In the medical equipment field, it is used to process connecting holes of surgical instruments, catheter holes of endoscopes, implant holes of dental implants, etc., to ensure the assembly precision and use safety of components; in the life science field, it can process rotor holes of laboratory centrifuges, stirring shaft holes of bioreactors, pipeline interface holes of chromatographs, etc., to meet the high-precision operation requirements of instruments. In addition, this technology is also applied in the machining of aerospace engine components, automobile gearbox parts, heat dissipation components of electronic chips, etc., providing support for precision manufacturing in various industries.

Machining Effect and Quality Control Key Points of Drilling and Boring Technology

The machining effect of drilling and boring technology is reflected in the geometric accuracy and surface quality of holes. Geometric accuracy includes roundness, perpendicularity, coaxiality, etc., and surface quality involves requirements for roughness and burr-free finish. Key points for quality control are as follows:

Tool selection: Select appropriate drill bits and boring tools according to workpiece materials (stainless steel, titanium alloy, engineering plastic);

Parameter optimization: Adjust the rotational speed, feed rate and cutting fluid usage to reduce tool wear and workpiece deformation;

Online detection: Real-time monitor the machining process through machine tool sensors and adjust parameters in a timely manner;

Post-processing: Such as deburring and cleaning to ensure that the spare parts meet the cleanliness requirements of the medical and life science fields.

Market Trend and Industrial Value of Drilling and Boring Technology

The global demand for precision manufacturing is growing continuously, and the compound annual growth rate of demand for high-precision spare parts in the medical equipment and life science fields remains at a high level. The development trend of drilling and boring technology will extend towards intelligence and automation, such as introducing AI to optimize machining parameters and realize unmanned production; green manufacturing is also an important direction, reducing the use of cutting fluid and energy consumption. The industrial value of this technology lies not only in improving machining efficiency and quality, but also in promoting technological innovation in the medical and life science fields and facilitating the localized replacement of high-end equipment.

As a core technology of precision manufacturing, drilling and boring technology solves the pain points of traditional hole machining through digital control and integrated machining. Its application in the manufacturing of medical equipment spare parts and life science spare parts provides a high-quality and high-consistency machining solution for the industry. For relevant manufacturing enterprises, mastering the core technology of this process or choosing professional machining service providers is the key to enhancing product competitiveness. With technological upgrading, drilling and boring technology will continue to support the high-quality development of the precision manufacturing field.