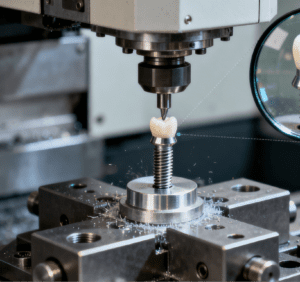

In the medical industry, “precision” is the gold standard for measuring the quality and performance of medical equipment. Exceptional precision is not only related to the performance of the equipment but also serves as a guarantee for patient safety. CNC 5-axis machining centers, with their exquisite processing capabilities and excellent precision control, continuously empower the quality and safety of medical equipment.

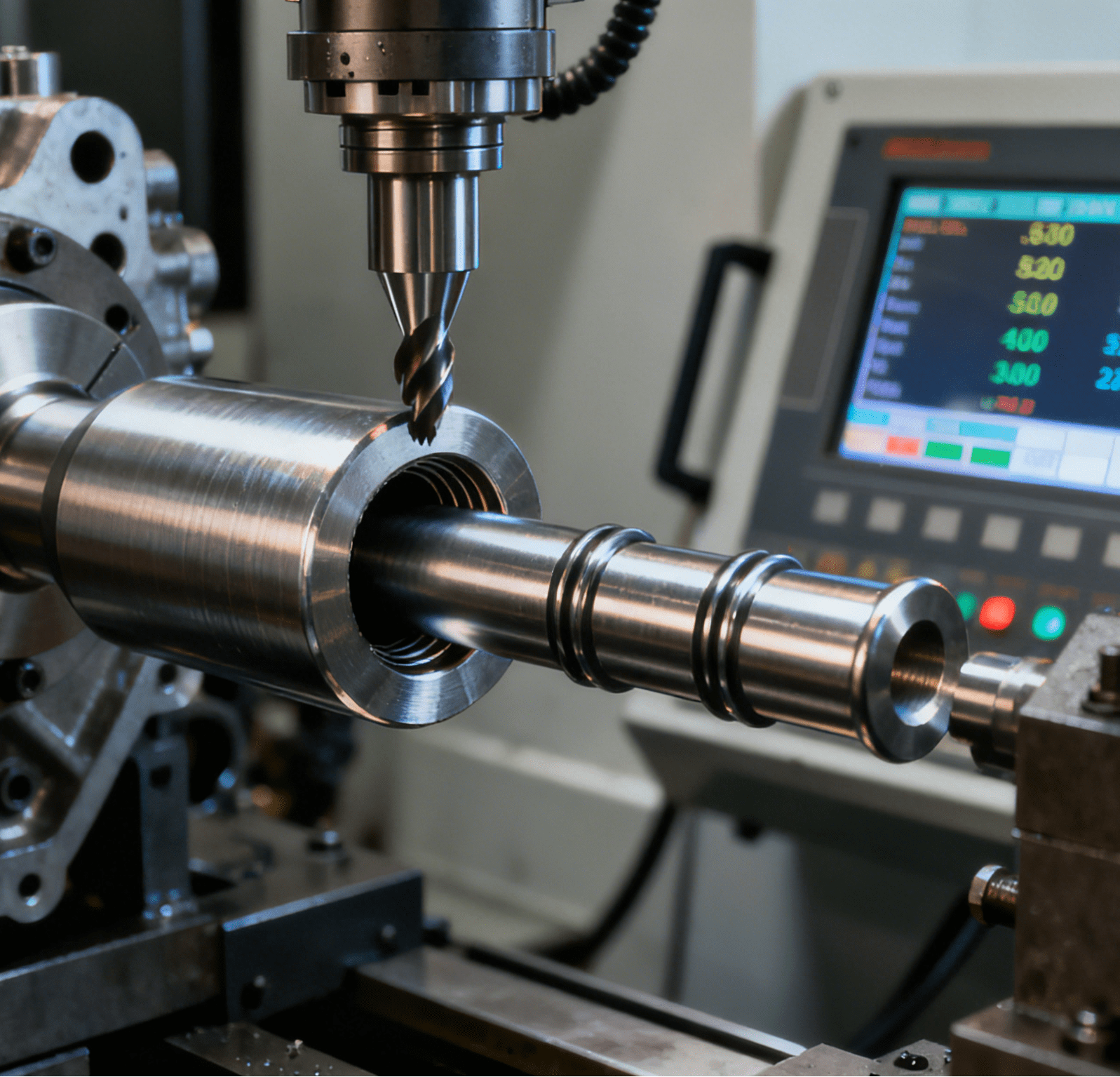

Advantages of CNC 5-Axis Machining

The greatest advantage of CNC 5-axis machining centers lies in their multi-axis linkage technology, which enables them to handle precision machining tasks of parts with complex geometries with ease. Currently, relying on rich technical experience, our team has been able to complete all machining processes of complex precision medical parts in a single setup by reducing the number of clamping operations and optimizing machining paths, effectively minimizing errors during the machining process.

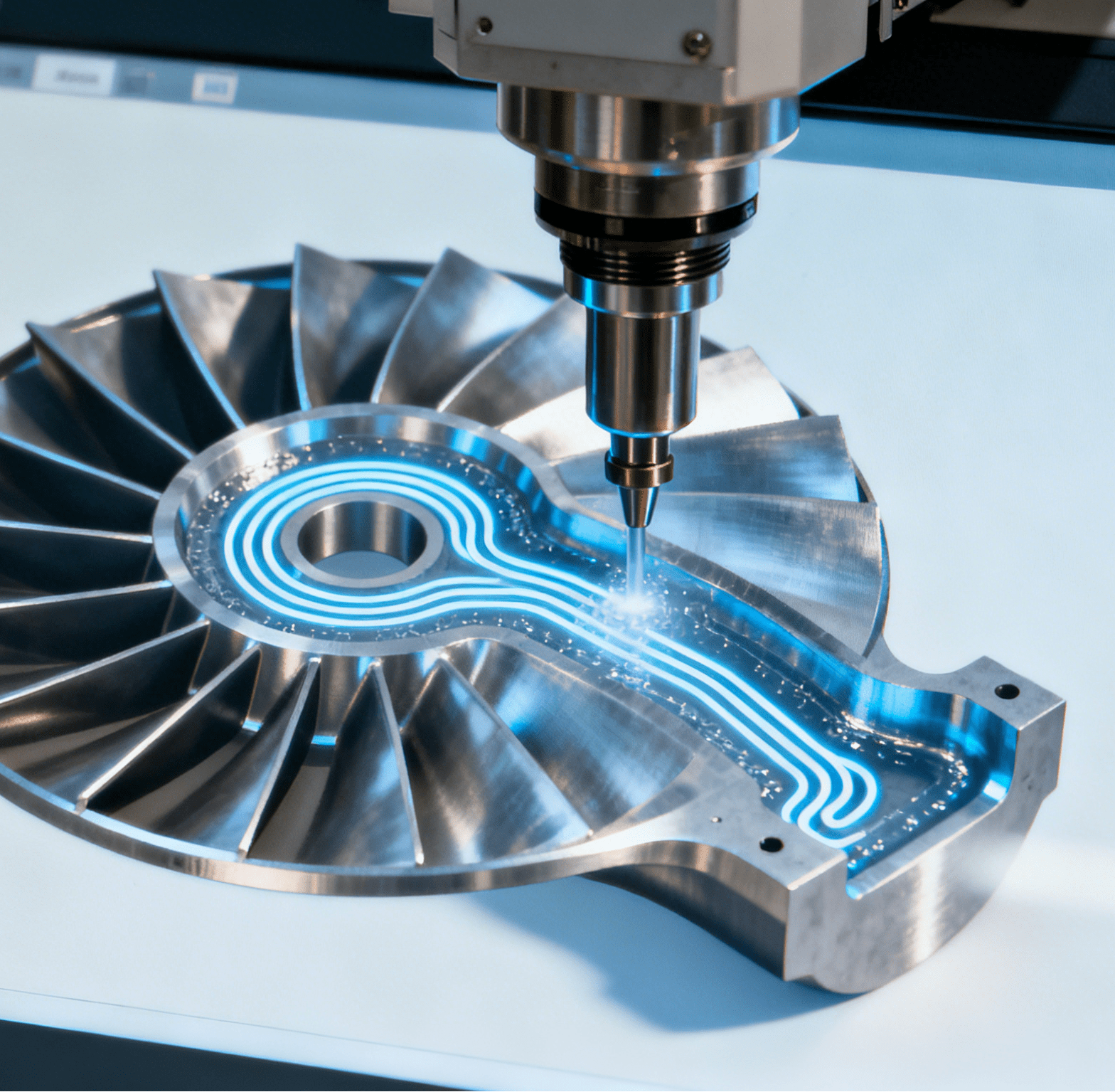

Strict Control of Precision Tolerances

Take the “medical drug bottle rotating plate” as an example. The complex shape design of this part is intended to ensure stable and precise rotational force during medical testing. Therefore, we use 5-axis machining equipment to quickly respond to design requirements, and by customizing engineering paths and optimizing process flows, we ensure that the angular tolerance of each hole position of the part is within the range of ±0.05°, realizing rapid mass production of the rotating plates.

Machining Processes and Material Selection

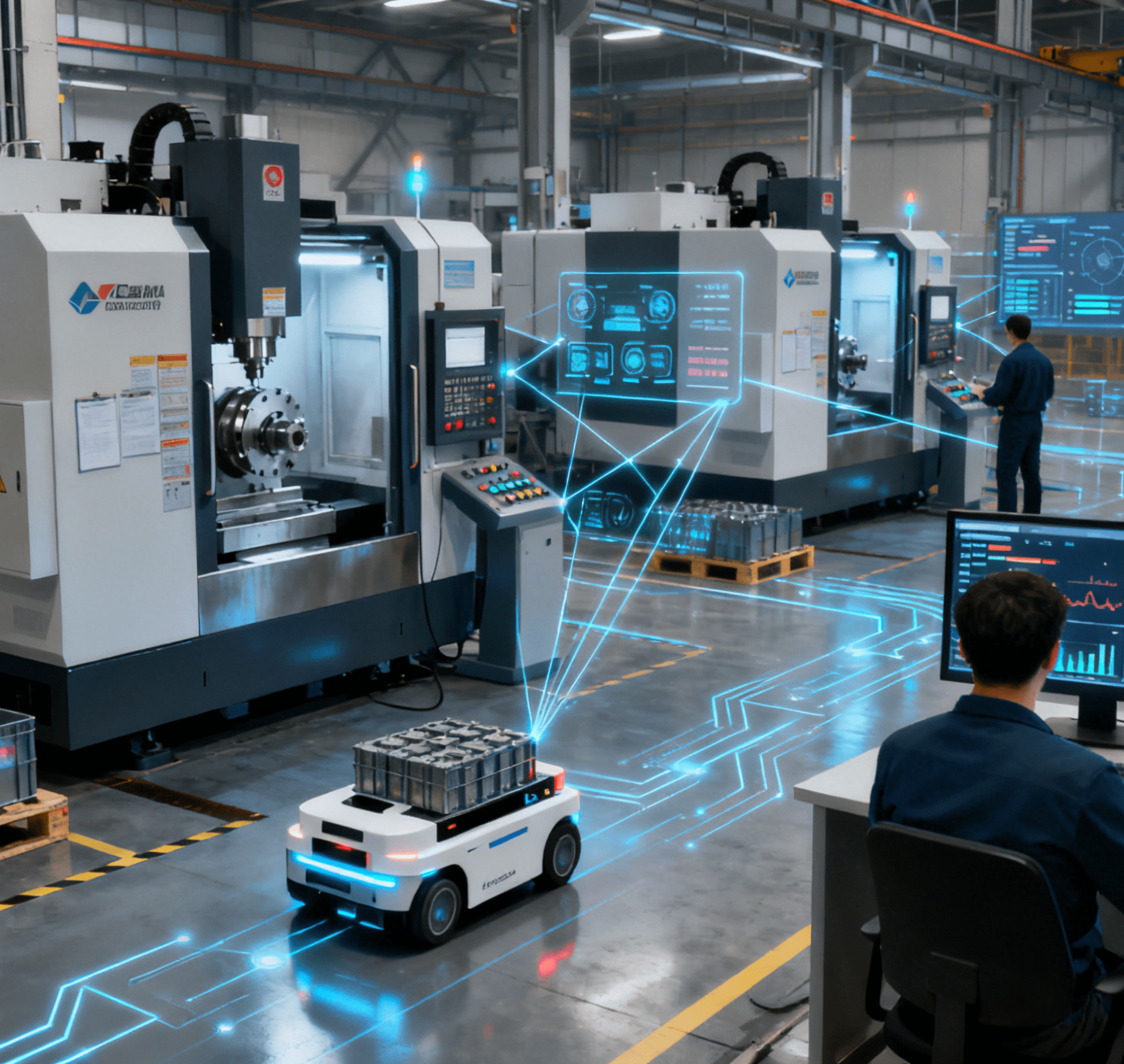

In terms of surface treatment processes, we adopt black anodization, which further enhances the wear resistance and corrosion resistance of the components and ensures high consistency of each product. In terms of materials, we fully consider the special application scenarios and machining complexity of the components, and specifically use AL6061 lightweight aluminum alloy as the raw material. This not only ensures high strength of the products but also provides greater flexibility for the realization of the parts’ shapes. Moreover, in the assembly process of medical parts that require nut fastening, we are equipped with Nut automatic assembly machines. These machines can achieve automatic feeding, positioning and tightening of nuts for CNC 5-axis machined precision parts, with assembly precision matching the machining accuracy of the parts, avoiding errors caused by manual assembly and further improving the overall quality stability of medical equipment.

Leveraging Potential Future Possibilities with Precision Technology

Looking ahead, Arie Precision Machinery will pay more attention to the introduction of advanced equipment and high-tech talents. Through continuous technological innovation and process optimization, we will bring more possibilities to the medical industry and provide safer and more reliable medical equipment for patients.