Table of Contents

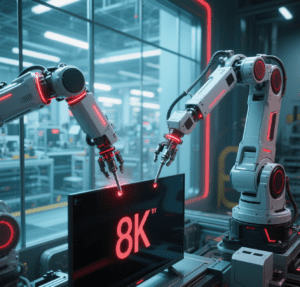

Toggle4-Axis Robotic TV Panel Screw-Fixing System: Redefining Precision in Large-Screen Assembly

In an era where TVs are racing toward larger sizes (up to 110”) and slimmer profiles (as thin as 6mm), the assembly process—especially screw-fixing panels to frames—has become a high-stakes balancing act. One misaligned screw can crack a panel, one loose screw can cause screen flickering, and one slow cycle can bottleneck an entire production line. Enter the 4-Axis Robotic TV Panel Screw-Fixing System—a SCARA-driven solution engineered to master these challenges with surgical precision, blistering speed, and unmatched adaptability.

Why 4-Axis? The Perfect Match for Planar Screw-Fixing

Four-axis SCARA robots are not just faster than their six-axis counterparts for flat-surface tasks—they’re purpose-built for them. Here’s why they dominate TV panel assembly:

1. Speed Without Sacrificing Precision

SCARA’s rigid horizontal arm and vertical stroke deliver pick-and-place cycles as fast as 0.5 seconds per screw, outpacing six-axis robots by 30–50% for planar motion. Yet, precision isn’t compromised: a repeatability of ±0.05mm ensures screws land perfectly in their holes, even on 8K panels with sub-millimeter screw pitches.

2. Cost-Effective Performance

With fewer moving parts than six-axis robots, 4-axis systems cost 30–50% less upfront and require 40% less maintenance. For TV manufacturers, this translates to a faster ROI—often within 12–18 months.

Core Technologies: Beyond Screwdriving, Into Mastery

The system integrates four breakthrough technologies to solve TV assembly’s toughest pain points:

1. Vision-Guided Positioning: Compensating for Imperfections

A 5MP vision system paired with deep-learning algorithms does more than locate screw holes—it adapts to real-world variability:

- Panel Warp Compensation: Corrects for up to ±0.5mm of panel warping or misalignment in the fixture.

- Dynamic Path Planning: Adjusts screw-fixing order to minimize robot travel time, shaving 10–15% off cycle times.

- Example: On a 65” OLED panel with 24 screws, the system maps the optimal sequence in milliseconds, avoiding collisions with delicate edges.

2. Torque-Control System: The Goldilocks Principle

Too much torque cracks the panel; too little causes loosening. The system’s closed-loop torque control ensures:

- Consistent torque (e.g., 10±0.5N·cm for a 55” LCD panel).

- Real-time feedback: If torque drifts outside tolerance, the robot halts and flags the issue.

- Data Traceability: Every screw’s torque is logged in the MES system, enabling end-to-end quality audits.

3. Adaptive End Effector: One Tool, Many Tasks

The end effector is a Swiss Army knife for screw-fixing:

- Quick-Change Bits: Swaps between M1.2 (for thin OLEDs) and M2.5 (for rugged outdoor TVs) in 10 seconds.

- Vacuum Gripping: Picks screws from feeders without scratching, even for black oxide-coated fasteners.

- Force Sensing: Detects if a screw is cross-threaded mid-drive, preventing panel damage.

4. Smart Screw Feeding: No Jams, No Downtime

A vibratory feeder + vision inspection module ensures screws are always ready:

- Orientation Check: Rejects upside-down or damaged screws (99.9% accuracy).

- Buffer Monitoring: Alerts operators when screw levels drop below 20%, preventing unexpected stops.

Solving TV Manufacturing’s Biggest Headaches

The system doesn’t just automate—it eliminates decades-old pain points:

1. Precision: From “Good Enough” to “Perfect”

Manual screwdriving averages a ±0.5mm positional error—enough to crack a panel or short-circuit internal wiring. The 4-axis system’s ±0.05mm precision ensures every screw sits flush, reducing post-assembly defects by 85%.

2. Speed: Doubling Throughput

A mid-sized TV factory using manual labor might fix 15 screws per minute per operator. The 4-axis system hits 30–40 screws per minute, slashing assembly time for a 65” panel from 5 minutes to 90 seconds. For a 600-unit/hour line, this means adding 240+ units to daily output.

3. Consistency: Torque You Can Trust

Human operators’ torque varies by ±3N·cm, leading to loose screws (causing rattling) or over-tightening (cracking panels). The system’s ±0.5N·cm consistency cuts such defects from 12% to <1%.

4. Flexibility: From 32” to 98” in 15 Minutes

Modular fixtures and pre-programmed recipes let the system switch between panel sizes in minutes. A single robot handles:

- 32” budget TVs (16 screws)

- 85” 8K flagship models (36 screws)

- Outdoor rugged TVs (heavier screws, higher torque)

Case Study: A Tier-1 TV Manufacturer’s Transformation

Consider a Chinese TV giant producing 1.2 million units/year. After adopting the 4-axis system:

- Throughput: Jumped from 150 units/hour to 300 units/hour (a 100% increase).

- Yield: Rose from 92% to 99.2%, saving $2.4M annually in rework and scrap.

- Labor Costs: Cut by 60% (reallocating 12 operators to higher-value tasks).

- Flexibility: Launched a new 98” model in 6 weeks (vs. 12 weeks historically) by reusing 80% of the system’s code and fixtures.

4-Axis vs. Alternatives: The Clear Winner

| Metric | 4-Axis Robotic System | Manual Assembly | 6-Axis Robot | Semi-Auto Machine |

| Speed | 30–40 screws/min | 3–5 screws/min | 15–20 screws/min | 10–15 screws/min |

| Precision | ±0.05mm | ±0.5mm | ±0.03mm* | ±0.2mm |

| Torque Consistency | ±0.5N·cm | ±3N·cm | ±0.5N·cm* | ±1N·cm |

| Changeover Time | <15 mins | Hours | 30–60 mins | 30 mins |

| Cost (CAPEX) | $50k–$120k | N/A (labor) | $150k–$250k | $80k–$150k |

| *Six-axis robots match torque and precision but sacrifice speed and cost. |

The Future: Smarter, Faster, More Connected

The 4-axis system is evolving beyond automation:

- AI-Predictive Maintenance: Sensors detect bearing wear or motor fatigue, scheduling maintenance before failures.

- Collaborative Workcells: Paired with cobots for semi-automated lines, letting humans handle complex tasks while robots fix screws.

- End-to-End Integration: Connects to ERP/MES systems for real-time production tracking and predictive scheduling.

For TV manufacturers, the 4-Axis Robotic Screw-Fixing System isn’t just a tool—it’s a catalyst for scaling premium, large-screen production without compromise. It turns the tiny act of screwdriving into a competitive advantage.

#4Axis TV Screw Fixing #SCARA Panel Assembly #Precision TV Automation