Table of Contents

ToggleAutomated Loading Assembly Machine for Electronic Components: Revolutionizing the Future of Electronics Manufacturing

Įvadas

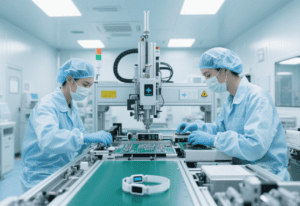

In the rapidly evolving electronics industry, where miniaturization, precision, and high-volume production are paramount, the assembly of electronic components has become a complex and critical process. Traditional manual and semi-automated assembly methods struggle to keep pace with the demands of modern devices, such as smartphones, laptops, and IoT gadgets. These methods suffer from limitations like low throughput (an average of 20–30 components assembled per minute), inconsistent quality (defect rates up to 2%), and high labor costs (accounting for 30–40% of production expenses). Automated Loading Assembly Machines (ALAMs) for electronic components have emerged as a game-changing solution, integrating advanced robotics, intelligent control systems, and high-precision handling technologies to redefine manufacturing efficiency and quality.

For instance, a leading smartphone manufacturer saw a 300% increase in daily production capacity after implementing an ALAM for circuit board assembly. The machine reduced labor requirements from 20 operators per line to just 5 while improving component placement accuracy from ±0.1mm to ±0.03mm. This not only cut production costs significantly but also enhanced product reliability, leading to a 15% reduction in warranty claims.

Technical Architecture: A Symphony of Precision and Automation

The effectiveness of ALAMs for electronic components lies in their sophisticated technical design, which seamlessly combines part handling, assembly, and quality control:

1. Automated Loading Sub-System

Tape-and-Reel Feeding Mechanisms

Tape-and-reel is the most common method for component loading in ALAMs. Components, such as resistors, capacitors, and integrated circuits (ICs), are pre-packaged in plastic tapes with precise spacing and fed into the machine via a spool. Servo-driven motors control the tape feed rate with sub-millimeter accuracy, ensuring components are presented to the pick-up point at the exact right time. For example, in the assembly of smartwatches, 0402-sized surface-mount devices (SMDs) with a footprint of just 1.0mm x 0.5mm can be precisely indexed and positioned for pick-up.

Tray Feeding Systems

For larger or irregularly shaped components—such as connectors, sensors, or camera modules—tray feeding systems offer versatility. These systems use robotic arms equipped with vacuum or mechanical grippers to pick components from trays. Vision systems with 3D structured light technology scan each component, calculating its orientation and position within milliseconds. This enables the machine to handle components with complex geometries, like angled connectors or components with multiple pins, with high precision.

2. High-Precision Assembly Unit

Pick-and-Place Robotic Systems

The heart of ALAMs is the pick-and-place robot, typically a multi-axis Cartesian or delta robot. Cartesian robots, known for their linear precision, can achieve placement accuracy of ±0.02mm, making them ideal for fine-pitch ICs with pins spaced as close as 0.3mm. Delta robots, on the other hand, offer high-speed performance, capable of placing up to 50,000 components per hour, which is crucial for high-volume production. End-effectors are customized for different component types; for example, vacuum nozzles are used for SMDs, while microgrippers handle delicate components like bare dies.

On-the-Fly Calibration and Alignment

To account for minor variations in component dimensions and board placement, ALAMs incorporate real-time calibration systems. Laser sensors and vision cameras continuously monitor the position of components and printed circuit boards (PCBs). If a deviation is detected, the robot adjusts its movement in real-time, ensuring that components are placed within the required tolerance. This dynamic alignment capability is essential for advanced packaging techniques, such as flip-chip bonding, where alignment accuracy below 10 microns is critical.

3. Integrated Quality Control

In-Line Automated Optical Inspection (AOI)

High-resolution AOI cameras (up to 50 megapixels) are integrated into the assembly process to detect defects immediately after component placement. These cameras use algorithms to analyze component orientation, solder joint quality, and missing or misaligned parts. For example, AOI can identify a bridged solder joint on a 0.5mm pitch IC, which could cause short circuits. Machine learning models continuously improve defect detection accuracy, reducing false positives by up to 70%.

X-Ray Inspection for Hidden Defects

For components with hidden solder joints, such as ball grid arrays (BGAs), X-ray inspection is employed. ALAMs equipped with X-ray capabilities can generate 2D or 3D images of the internal structure, revealing voids, cold joints, or misaligned balls. This non-destructive testing method ensures that only defect-free boards progress to the next stage of production.

4. Intelligent Control and Monitoring System

A combination of Programmable Logic Controllers (PLCs) and industrial PCs manages the entire assembly process. PLCs handle real-time operations, such as controlling motor speeds and robotic movements, with sub-millisecond response times. Industrial PCs run advanced software for production scheduling, recipe management, and data analytics. Internet of Things (IoT) connectivity allows manufacturers to monitor machine performance remotely, collect data on key metrics like Overall Equipment Effectiveness (OEE), and predict maintenance needs using predictive analytics.

Industry Applications: Transforming Electronics Production

ALAMs have become indispensable across various electronics sectors:

1. Consumer Electronics

Išmaniojo telefono surinkimas

In smartphone manufacturing, ALAMs handle the intricate assembly of dozens of components, from tiny SMD resistors and capacitors to complex camera modules and flexible printed circuits. The machines can place components on both sides of the PCB, enabling compact device designs. A major smartphone brand reduced its assembly time from 45 minutes to 18 minutes per unit, accelerating time-to-market and increasing annual production by 2 million devices.

2. Automotive Electronics

In-Car Infotainment and ADAS Systems

Automotive electronics demand high reliability and precision. ALAMs assemble components for advanced driver assistance systems (ADAS), such as radar sensors and LiDAR modules, with strict adherence to automotive standards like ISO 26262. The machines ensure that components can withstand harsh environments, including extreme temperatures and vibrations, by precisely applying thermal interface materials and securing components with torque-controlled fasteners.

3. Medical Electronics

Wearable Health Monitors

For medical devices like wearable ECG monitors or insulin pumps, ALAMs guarantee the accuracy and safety of electronic assemblies. The machines operate in cleanroom environments, using anti-static measures to protect sensitive components. Additionally, traceability features record every assembly step, enabling full compliance with regulatory requirements like FDA 21 CFR Part 820.

4. Aerospace and Defense

Avionics Systems

In aerospace applications, ALAMs assemble high-reliability components for avionics systems. The machines can handle specialized components, such as hermetically sealed connectors and radiation-hardened ICs, with extreme precision. By reducing human error, ALAMs contribute to the stringent safety requirements of aircraft and space vehicles, where component failure rates must be near-zero.

Technological Frontiers: Shaping the Next Generation of ALAMs

1. Artificial Intelligence and Machine Learning Integration

AI and ML algorithms are increasingly being used to optimize ALAM performance. These technologies can analyze vast amounts of production data to predict component shortages, adjust assembly parameters in real-time to compensate for material variations, and even autonomously diagnose and resolve minor machine malfunctions. For example, an ML model can learn from historical defect data to identify patterns and proactively prevent quality issues.

2. Miniaturization and Microassembly Capabilities

As electronics continue to shrink, ALAMs are evolving to handle components at the micro and nano scales. Newer machines can place components as small as 01005 SMDs (0.4mm x 0.2mm) and perform microbonding techniques, such as thermocompression bonding for semiconductor packaging. Advanced microscopy systems integrated into the machines provide real-time visual feedback during microassembly operations.

3. Sustainable Manufacturing Features

Future ALAMs will prioritize eco-friendly practices. Energy-efficient servo motors, recyclable material handling, and reduced waste generation through optimized component placement will become standard. For instance, machines may use algorithms to minimize the use of adhesives and soldering materials, contributing to a more sustainable production process.

Įgyvendinimo iššūkiai ir sprendimai

1. Didelė pradinė investicija

The cost of a high-end ALAM can exceed $500,000. However, manufacturers can offset this through long-term savings in labor costs, reduced scrap rates, and increased production volumes. Leasing options, government incentives for automation, and pay-per-use models are also emerging as viable alternatives.

2. Complex Programming and Setup

Configuring an ALAM for different products requires specialized programming skills. To address this, user-friendly software with drag-and-drop interfaces and pre-built assembly recipes is becoming more common. Additionally, training programs offered by equipment manufacturers help operators quickly learn machine programming and maintenance.

3. Integration with Existing Production Lines

Retrofitting ALAMs into existing production lines can be challenging due to space constraints and compatibility issues. Modular and compact designs, along with standardized communication protocols (e.g., OPC UA), simplify integration, allowing seamless connectivity with other manufacturing equipment.

Conclusion

Automated Loading Assembly Machines for electronic components have emerged as the backbone of modern electronics manufacturing, enabling faster production, higher quality, and greater flexibility. As technology continues to advance, these machines will play an even more critical role in meeting the growing demand for innovative electronic devices. By embracing AI, miniaturization, and sustainability, ALAMs are not only streamlining production but also driving the industry towards a future of smart, efficient, and eco-friendly manufacturing.

#automated machinery #automated assembly machine #electronic components