Table of Contents

ToggleCatheter Assembly Machines: Revolutionizing Minimally Invasive Medicine through Precision and Automation

Įvadas

In the realm of modern medical devices, catheters have emerged as indispensable tools for minimally invasive procedures, diagnostic imaging, and drug delivery. The precision and reliability of catheters directly impact patient outcomes, making their assembly a critical process. Traditional manual catheter assembly methods are fraught with challenges such as inconsistent quality, low production efficiency, and high labor costs. Catheter assembly machines have emerged as a game – changer, integrating advanced automation, precision engineering, and intelligent control systems to transform the manufacturing landscape.

Technical Architecture of Catheter Assembly Machines

1. Precision Extrusion and Tubing Handling

The foundation of catheter manufacturing lies in the production of high – quality tubing. Catheter assembly machines are equipped with state – of – the – art extrusion systems. These systems precisely control parameters such as temperature, pressure, and extrusion speed to produce tubing with consistent wall thickness (tolerance within ± 0.01 mm) and outer diameter. For example, PEEK (Polyetheretherketone) and polyurethane, two commonly used materials in catheter construction, require meticulous extrusion control to ensure optimal mechanical properties.

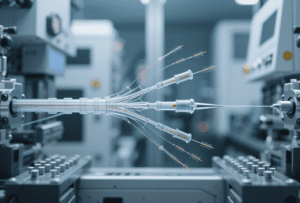

Once extruded, the tubing is fed into automated handling units. These units use servo – driven rollers and robotic arms to cut the tubing to the exact required lengths. Vision – based systems are employed to inspect the cut edges for burrs or irregularities, ensuring that only defect – free tubing segments proceed to the next assembly stages.

2. Tip and Port Assembly

The tip of a catheter is a crucial component, as it directly interacts with the patient’s body. Catheter assembly machines utilize micro – robotic systems for tip shaping and attachment. For example, in the case of angioplasty catheters, the tip needs to be precisely shaped to navigate through the complex network of blood vessels. Laser – cutting technology integrated into the machines can create intricate tip geometries with a precision of up to 50 microns.

Port assembly, which is essential for functions like fluid infusion or sample withdrawal, also benefits from automation. The machines can accurately position and attach ports of various sizes and types onto the catheter tubing. High – precision dispensing systems are used to apply medical – grade adhesives, ensuring a secure and leak – proof bond. Pressure – testing stations immediately follow port attachment, subjecting the assembled units to pressures equivalent to those experienced during clinical use to detect any potential leaks.

3. Braiding and Reinforcement Integration

Many catheters, especially those used in high – pressure applications like urology or interventional cardiology, require reinforcement. Catheter assembly machines are designed to integrate braiding processes seamlessly. Advanced braiding heads can weave fine metal wires (such as stainless steel or nitinol) or synthetic fibers around the catheter tubing. The machines control the braiding angle, pitch, and tension with extreme accuracy. For instance, a change in braiding angle by as little as 1° can significantly impact the catheter’s torqueability and pushability.

After braiding, the machines apply a protective outer layer, often through co – extrusion or dipping processes. This outer layer not only safeguards the braided structure but also provides a smooth surface for easy insertion into the body.

4. Intelligent Control and Monitoring Systems

The “brain” of catheter assembly machines is the intelligent control system. These systems typically use a combination of Programmable Logic Controllers (PLCs) and industrial PCs. PLCs are responsible for real – time control of the machine’s mechanical and electrical components, ensuring that all movements and operations occur with split – second precision.

Industrial PCs, on the other hand, handle higher – level functions such as process optimization, quality control, and data management. Machine learning algorithms can be integrated into these systems to analyze production data in real – time. For example, if the system detects a slight deviation in the tubing wall thickness over a series of products, it can automatically adjust the extrusion parameters to correct the issue, minimizing waste and maintaining consistent quality.

Vision inspection systems play a vital role in quality control. High – resolution cameras equipped with image – processing software can detect defects as small as a few microns, such as scratches, bubbles in the tubing, or improper port alignment. Any defective units are immediately rejected, and the data is logged for further analysis.

Industry Applications of Catheter Assembly Machines

1. Cardiology

In cardiology, catheters are used for a wide range of procedures, from coronary angiography to stent implantation. Catheter assembly machines enable the production of highly specialized catheters with unique features. For example, machines can manufacture catheters with multiple lumens, each with a precisely controlled diameter, to allow for simultaneous delivery of contrast agents, guidewires, and other instruments.

A leading medical device manufacturer in the cardiology field, after implementing a new generation of catheter assembly machines, was able to reduce the production time of complex coronary catheters by 30%. The improved precision also led to a 20% decrease in post – production rejection rates, resulting in significant cost savings and increased market competitiveness.

2. Urology

Urological catheters require specific design features to ensure patient comfort and effective treatment. Catheter assembly machines can produce catheters with advanced balloon designs for procedures like ureteral stenting. The machines can precisely control the inflation and deflation characteristics of the balloons by accurately shaping the balloon material and integrating inflation ports.

In addition, the machines can incorporate hydrophilic coatings onto the catheter surface. These coatings are applied with high precision, ensuring uniform coverage and optimal lubricity, which reduces patient discomfort during insertion and removal. A urology device company reported a 15% increase in customer satisfaction after upgrading to automated catheter assembly machines due to the improved quality and consistency of their products.

3. Neurology

Neurological catheters are used for delicate procedures within the brain and spinal cord. The assembly of these catheters demands extreme precision. Catheter assembly machines can produce catheters with ultra – small diameters (down to 0.5 mm) and complex tip geometries. The machines’ ability to accurately place micro – electrodes or sensors at specific locations along the catheter is crucial for procedures such as deep brain stimulation.

Automated assembly also ensures that the catheters have consistent mechanical properties, which is essential for navigating through the tortuous pathways of the nervous system. A neurological device startup was able to scale up its production rapidly after adopting catheter assembly machines, meeting the growing demand for minimally invasive neurological treatment devices.

Future Trends in Catheter Assembly Machines

1. 3D Printing Integration

The integration of 3D printing technology into catheter assembly machines is on the horizon. 3D printing allows for the creation of highly customized catheters tailored to individual patient needs. By combining 3D printing with traditional assembly processes, machines could produce catheters with complex internal structures, such as lattice – like supports for enhanced flexibility or patient – specific geometries based on pre – operative imaging data. This trend has the potential to revolutionize personalized medicine in minimally invasive procedures.

2. Internet of Things (IoT) Connectivity

Future catheter assembly machines are likely to be equipped with IoT capabilities. This would enable real – time monitoring of the machines from remote locations. Manufacturers could track production data, machine performance, and maintenance needs in real – time across multiple production facilities. IoT – enabled machines could also communicate with other devices in the medical supply chain, such as inventory management systems, to ensure seamless production and delivery of catheters.

3. Nanotechnology – Enabled Features

Nanotechnology is expected to have a significant impact on catheter design, and catheter assembly machines will need to adapt accordingly. For example, machines may be required to integrate nanocoatings with anti – bacterial or anti – thrombotic properties onto catheters. These coatings need to be applied with atomic – level precision, which will drive the development of new deposition techniques and control systems within the assembly machines.

Challenges and Considerations in Implementing Catheter Assembly Machines

1. Regulatory Compliance

The medical device industry is highly regulated, and catheter assembly machines must comply with strict standards such as ISO 13485 and FDA regulations. Every aspect of the machine’s operation, from the materials used in construction to the quality control processes, needs to be documented and validated. Ensuring regulatory compliance adds complexity and cost to the implementation of these machines, as manufacturers need to invest in extensive testing, documentation, and quality management systems.

2. Initial Investment and Training

Catheter assembly machines represent a significant capital investment. The cost of purchasing, installing, and commissioning a high – end machine can range from several hundred thousand to several million dollars. In addition, training the workforce to operate and maintain these machines requires specialized knowledge in automation, medical device manufacturing, and quality control. Manufacturers need to carefully consider the return on investment and develop comprehensive training programs to ensure that their employees can fully utilize the machines’ capabilities.

3. Adaptability to New Materials and Designs

The field of medical device materials and catheter designs is constantly evolving. Catheter assembly machines need to be adaptable to accommodate new materials with different processing requirements and novel catheter designs. This may require frequent upgrades to the machine’s hardware and software, as well as the development of new assembly techniques. Manufacturers must be prepared to invest in research and development to keep their assembly machines up – to – date with the latest industry trends.

Conclusion

Catheter assembly machines have become an essential part of the modern medical device manufacturing ecosystem. Their ability to combine precision, automation, and intelligent control has transformed the production of catheters, leading to improved product quality, increased production efficiency, and enhanced patient outcomes. As technology continues to advance, these machines will play an even more crucial role in meeting the growing demand for innovative and personalized medical devices. While challenges such as regulatory compliance, high initial investment, and the need for adaptability exist, the long – term benefits of using catheter assembly machines far outweigh the costs, making them a worthy investment for medical device manufacturers.

#catheter assembly #catheter design #catheter assembly automation