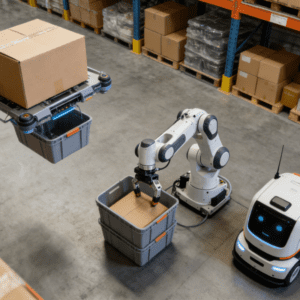

In a warehousing scenario, an embodied picking robot is sorting and delivering parts beside the shelves. It can even automatically change the end effectors of its robotic arms according to the shapes of the parts, with skillful and smooth movements. Meanwhile, multiple supporting logistics robots are collaborating at the test site to achieve accurate picking and efficient delivery of different parts…

This is a robot operation scenario that took place on January 6 at the Robot Test Center of Chengdu Ruixinhang Technology Co., Ltd. (hereinafter referred to as “Ruixinhang”), an enterprise located in the Chengdu High-tech Zone.

Three “World Firsts”: Core Breakthroughs in Embodied Picking Technology

This achievement embodies three “firsts”: Ruixinhang’s pioneering ADA-Grasp industrial embodied grasping technology, the world’s first industrial embodied picking robot requiring no training, and the first-launched integrated flexible embodied solution for warehousing picking.

In 2025, Ruixinhang successfully rolled out the world’s first industrial embodied picking robot with zero-training requirement. Endowed with a “smart brain” and “flexible hands”, this robot features the advantage of “deployment without prior training”, which can well address the current industry pain points of embodied robots, such as high training costs and expensive equipment investment.

ADA-Grasp Technology: Solving High-Cost Pain Points with Zero-Training Deployment

Take the specific task of “factory part picking” as an example. In industrial scenarios, parts come in a wide variety of shapes and sizes, and new types of parts need to be grasped by robots at any time. For traditional robots equipped with large models, the emergence of new parts requires several days or even more than a week of retraining. In the meantime, enterprises also have to rent high-computing-power AI training servers and high-precision 3D cameras costing tens of thousands of yuan… All of these will lead to increased time and economic costs.

The ADA-Grasp industrial embodied grasping technology released by Ruixinhang precisely solves such pain points. Integrating the “VLA large model” and “human brain-like” adaptive learning capability, this technology eliminates cumbersome model training processes. Faced with new parts of various specifications and shapes, the robot can realize “instant deployment” with zero training, thus effectively reducing costs.

From Products to Solutions: Redefining Intelligent Warehousing with Integrated Systems

With its large model and robot products in place, Ruixinhang then turned its focus to embodied solutions. In November 2025, the series of industrial embodied picking robot products (including flying bin robots, embodied picking robots and embodied delivery robots), jointly developed by Ruixinhang and Zhongli Co., Ltd., made their global debut. Highlighted by technological breakthroughs in “high efficiency, high precision and low cost”, these products aim to redefine the new form of intelligent warehousing through embodied intelligence.

At the test center, an embodied picking robot with a humanoid upper body and a wheeled chassis is performing part picking and delivery tasks. Faced with parts of different shapes and sizes, the robot can “intelligently” identify them and select one of its left and right robotic arms for picking based on the most suitable method for the specific part. This is Ruixinhang’s first-launched integrated flexible embodied solution for warehousing picking. First, the flying bin robot moves bins from any position on the shelves to the picking point within seconds. Then, the embodied picking robot sorts the parts and the embodied delivery robot delivers them. The entire process from warehouse picking to workstation delivery can be fully automated, replacing manual labor and covering diverse scenarios ranging from e-commerce retail to intelligent manufacturing.

In addition, for more complex picking scenarios, Ruixinhang has pioneered an embodied intelligent picking station that can switch the end effectors of robotic arms in real time, and also endowed embodied intelligence with “sharp eyesight”. Through visual perception or information interaction, this solution identifies parts of various forms and selects different robotic arm end effectors (such as grippers, suction cups, magnetic attractors, dexterous hands, etc.) in real time for efficient grasping, achieving unmanned picking operations.

In November 2025, Ruixinhang also released a thousand-unit cluster robot scheduling system, which serves as the command center for thousands of robots. According to reports, this robot scheduling system integrates intelligent task allocation, real-time path planning, traffic management strategies and in-depth data insights. Equipped with advanced intelligent scheduling algorithms, it supports flexible configuration of business processes. Like a strategizing “dispatcher”, it can “direct” thousands of robots to work flexibly and efficiently, ensuring optimal resource allocation and maximization of overall scheduling efficiency in complex dynamic environments.