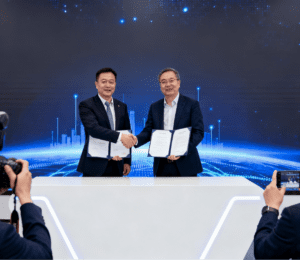

New Deal Details: UQI Signs RMB 30M Contract with Tianqi Co., Ltd. for Walker S Series

Recently, UQI, UBtech’s intelligent logistics subsidiary, formally inked a procurement contract with Tianqi Automation Engineering Co., Ltd. (“Tianqi Co., Ltd.”). Tianqi will purchase UBtech’s industrial humanoid robot Walker S series at a total price of RMB 30 million, with delivery scheduled by December 31, 2025. The collaboration builds on their long-term strategic partnership established in June 2023 (via a Strategic Cooperation Framework Agreement), focusing on humanoid robot applications in new energy vehicles, 3C electronics, and intelligent logistics—including scenarios like optimizing 자동 버클 공급 및 조립 (a key process in auto interior and electronic device shell production) to drive high-end manufacturing development.

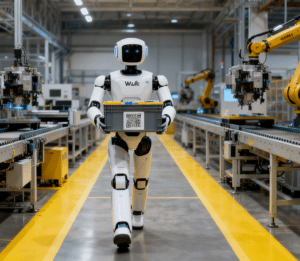

Cumulative Orders Near RMB 430M: Highlights Include World’s Largest Humanoid Robot Contract

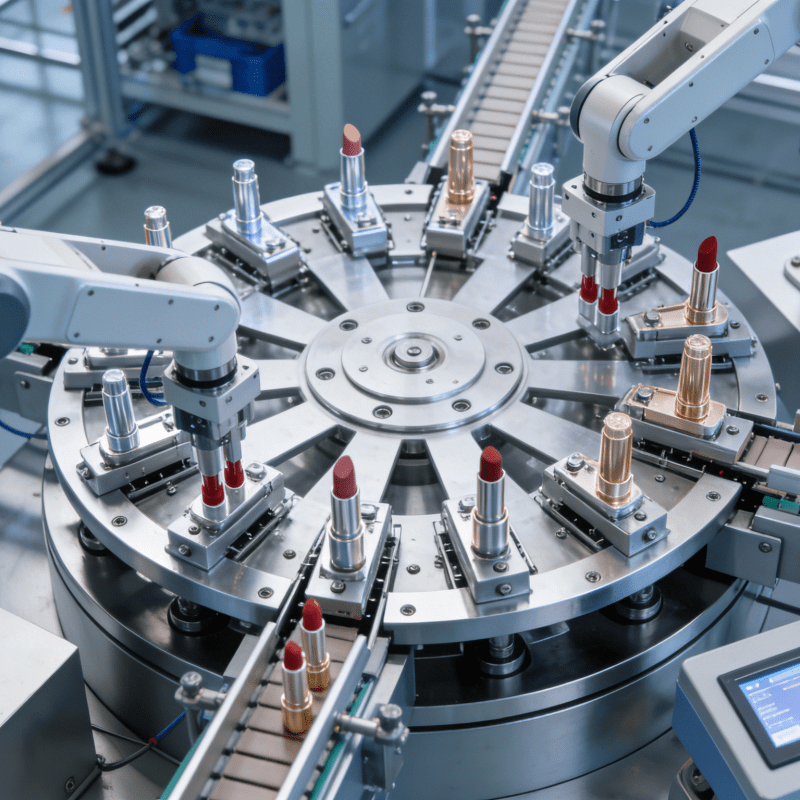

Including the latest deal, UBtech’s Walker series humanoid robots have now secured contracts worth nearly RMB 430 million. This figure covers nearly RMB 50 million in orders delivered in H1 2025 (excluding orders for the full-size research/education robot Tiangong Walker). A key milestone came in September: UBtech won a RMB 250 million contract for embodied intelligent humanoid robot products and solutions from a leading domestic enterprise—currently the world’s largest humanoid robot contract, with the Walker S robots set to support core industrial processes like Automatic Buckle Feeding And Assembly by integrating AI visual recognition to solve issues like buckle posture deviation and assembly misalignment.

Global Enterprise Partnerships & Future Plans: Scaling Mass Production for Real-Scenario Use

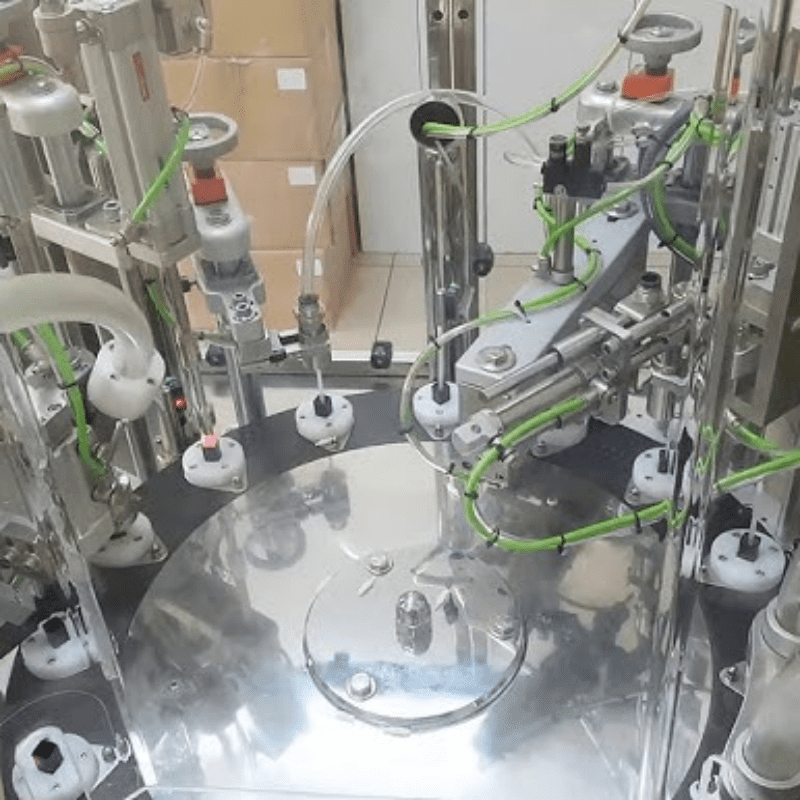

UBtech now collaborates with renowned enterprises across new energy vehicle manufacturing, 3C manufacturing, and intelligent logistics, such as BYD, Geely Automobile, FAW-Volkswagen, Foxconn, and SF Express. Its industrial humanoid robot Walker S series has entered the most factories globally for training, with proven value in streamlining Automatic Buckle Feeding And Assembly workflows: for instance, at BYD’s auto interior production lines, Walker S robots work in tandem with dedicated feeding systems to automatically identify, grab, and assemble plastic buckles for door panels—cutting manual intervention time by 40% and raising assembly pass rates from 95% to 99.8%. Looking ahead, UBtech will enhance the mass production capacity of Walker series robots to meet order demands and accelerate their application in real-world scenarios, including deeper integration with precision assembly processes like automatic buckle feeding.

Robots realize the automated assembly of automotive connectors