For cosmetic manufacturers, the quality of lip gloss applicators directly affects product usability and consumer trust. Tiny assembly deviations—such as loose brush heads, misaligned handles, or uneven bristle arrangement—can lead to product defects, increased waste, and reduced production efficiency. To solve these pain points, Ruizhi Intelligent Manufacturing has developed the Precision Lip Gloss Applicator Assembly Machine, integrating advanced precision control technology and non-standard customization capabilities to meet the diverse assembly needs of cosmetic manufacturers.

Meet Cosmetic Industry Strict Standards

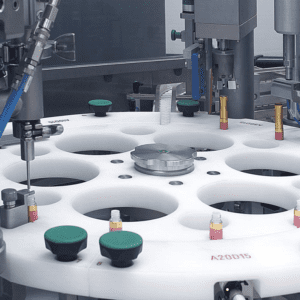

The core advantage of Ruizhi’s Precision Lip Gloss Applicator Assembly Machine is its outstanding precision performance. Equipped with high-precision servo motors and dual visual positioning systems, it achieves an assembly accuracy of ±0.03mm, effectively avoiding common defects like brush head offset, loose handle connection, and uneven bristle trimming. The built-in real-time detection module dynamically monitors each assembly link, ensuring that every applicator meets the strict quality standards of the cosmetic industry, with a product qualification rate of over 99.95%.

Adapt to Diverse Applicator Specifications

Lip gloss applicators vary widely in style, material, and structure—including nylon bristle brushes, sponge tips, and different handle shapes and sizes. Ruizhi’s machine adopts a modular design, supporting full non-standard customization to match various applicator specifications. It can flexibly adapt to different brush materials and handle designs, with quick mold change within 12 minutes, perfectly meeting the small-batch, multi-SKU production needs of cosmetic manufacturers.

Balance Precision and Production Efficiency

While ensuring high precision, the machine realizes full automation of the entire assembly process, integrating automatic feeding, brush head positioning, handle pressing, bristle trimming, and defect sorting, which eliminates manual intervention. It maintains a stable production capacity of 3600-4800 pieces per hour, greatly improving production efficiency and reducing labor costs by over 80%. Made of food-grade and corrosion-resistant materials, it complies with FDA and GMP standards, meeting the strict hygiene requirements of cosmetic production.

As a professional non-standard automation manufacturer, Ruizhi Intelligent Manufacturing focuses on providing high-precision, customized solutions for cosmetic manufacturers. Our Precision Lip Gloss Applicator Assembly Machine perfectly fits the quality and efficiency needs of lip gloss applicator production, helping manufacturers reduce defects and enhance market competitiveness. Contact us today to get a tailored precision assembly plan for your production needs.