Table of Contents

TogglePrecision and Compliance: The Evolution and Impact of Biological Indicator Assembly Machines

I. The Critical Role of Biological Indicators in Sterilization Assurance

In the highly regulated fields of pharmaceuticals, medical device manufacturing, and healthcare, biological indicators (BIs) serve as the gold standard for validating sterilization processes. These small, yet crucial devices contain live spores of highly resistant microorganisms—such as Geobacillus stearothermophilus for steam sterilization or Bacillus atrophaeus for ethylene oxide (EO) treatments—and confirm that sterilization procedures have achieved the required lethality (e.g., a 6-log reduction).

Traditional manual assembly of BIs faced significant challenges: inconsistent spore loading (variance in spore counts exceeding ±10%), high contamination risks (human error leading to false positives), and limited production scalability. Biological indicator assembly machines have revolutionized this process by integrating precision robotics, aseptic handling, and real-time quality control, ensuring regulatory compliance with standards like ISO 11138 and AAMI ST72. For instance, a leading pharmaceutical company reduced BI batch failure rates from 3.2% to 0.4% after adopting automated assembly lines, saving over $2 million annually in rework and validation costs.

II. Technical Architecture: A Synergy of Precision and Aseptic Control

Biological indicator assembly machines combine advanced engineering with strict contamination control to deliver reliable, high-quality products. Their functionality hinges on four interconnected modules:

1. Spore Preparation and Loading System

At the heart of BI production lies the precise handling of microbial spores:

- Microbial Culture and Harvesting: Automated bioreactors cultivate spore-forming strains under controlled conditions (e.g., temperature 55°C, pH 7.2 for stearothermophilus), followed by centrifugation and washing steps to isolate pure spore suspensions.

- Nano-Dispensing Technology: Piezoelectric or microvalve-based dispensers deposit picoliter volumes of spore suspensions onto carriers with ±2% accuracy. Some systems use ultrasonic atomizers to achieve homogenous spore distribution, ensuring consistent spore counts (e.g., 1×10⁶ CFU per BI).

2. Aseptic Assembly Unit

To maintain sterility, assembly occurs within Class 5 (ISO 5) cleanrooms with strict barrier isolator systems:

- Robotic Manipulation: Six-axis sterile robots equipped with single-use end-effectors perform tasks like carrier insertion, vial capping, and label application. These robots are designed to minimize particulate generation, often coated with electro-polished stainless steel or PTFE materials.

- Hermetic Sealing: Laser welding or ultrasonic sealing technologies create airtight seals for BI containers, preventing spore leakage during sterilization and transportation. Leak testing is conducted using helium mass spectrometry, detecting leaks as small as 1×10⁻⁹ Pa·m³/s.

3. Real-Time Quality Assurance and Monitoring

Multi-layered inspection systems ensure each BI meets stringent specifications:

- Optical and Microscopic Analysis: High-resolution cameras combined with image processing algorithms verify spore carrier placement, label integrity, and container defects. In-line microscopy can detect clumps or abnormal spore morphology, automatically rejecting non-compliant units.

- Bioburden Testing Integration: Some advanced machines incorporate rapid ATP bioluminescence assays to confirm the absence of extraneous microbial contamination in assembled BIs, reducing testing time from 24 hours to 30 minutes.

4. Traceability and Data Management

Compliance with 21 CFR Part 11 and GMP requires comprehensive data tracking:

- RFID and Barcode Traceability: Each BI is tagged with unique identifiers, enabling end-to-end tracking from raw material sourcing to final distribution. Data on spore batch numbers, assembly timestamps, and quality test results are stored in encrypted databases.

- Digital Twin Technology: Manufacturers use virtual models to simulate assembly processes, optimize production parameters, and predict equipment maintenance needs, reducing unplanned downtime by up to 70%.

III. Industry Applications: From Pharmaceuticals to Space Exploration

Biological indicator assembly machines have diverse applications across industries with zero-tolerance for contamination:

1. Pharmaceutical Manufacturing

- Case: A global vaccine producer deployed automated BI lines to validate steam sterilization of vial filling equipment. The system’s ability to produce 10,000 BIs per day with 99.8% accuracy enabled faster batch release, reducing time-to-market by 15%.

- Technical Edge: Integrated autoclave simulation chambers allow BIs to undergo pre-sterilization stress testing, mimicking real-world processing conditions to enhance reliability.

2. Medical Device Sterilization

- Case: A medical device company adopted EO-compatible BI assembly machines to meet FDA requirements for complex surgical instruments. The automated process ensured consistent spore viability, leading to a 40% reduction in failed sterilization cycles.

- Technical Edge: EO-resistant materials and specialized gas-tight seals prevent chemical degradation of BIs during exposure to sterilizing agents.

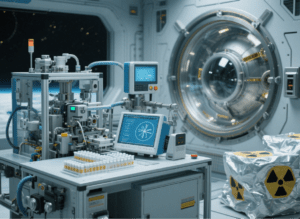

3. Space Exploration

- Case: NASA uses custom-built BI assembly systems to prepare biological indicators for spacecraft decontamination. These machines operate in vacuum chambers to simulate space conditions, ensuring BIs remain viable during long-duration missions.

- Technical Edge: Radiation-resistant packaging and low-outgassing materials protect BI integrity in the harsh space environment.

IV. Future Trends: AI, Sustainability, and Regulatory Evolution

As technology and regulations advance, biological indicator assembly machines are poised for further innovation:

1. Artificial Intelligence and Machine Learning

- Predictive Process Control: AI algorithms analyze real-time data from sensors (e.g., temperature, humidity, spore count) to predict and prevent assembly anomalies, reducing waste by up to 30%.

- Adaptive Spore Cultivation: Machine learning models optimize bioreactor conditions based on historical spore performance data, enhancing spore viability and reducing culture time.

2. Sustainable Design and Green Manufacturing

- Biodegradable BI Carriers: Development of plant-based materials (e.g., cellulose nanofibers) replaces traditional plastics, reducing environmental impact without compromising performance.

- Energy-Efficient Operation: Next-generation machines use servo motors with regenerative braking and LED lighting systems, cutting energy consumption by 40%.

3. Regulatory Harmonization and Global Standards

- Digital Compliance Tools: Software platforms automate documentation and reporting, streamlining audits and ensuring compliance with evolving international standards (e.g., WHO prequalification requirements).

- Blockchain Integration: Some manufacturers explore blockchain technology to create immutable records of BI production, enhancing supply chain transparency and anti-counterfeiting measures.

V. Implementation Challenges and Considerations

Deploying biological indicator assembly machines requires careful planning:

- Validation Complexity: Extensive process validation (e.g., installation qualification, operational qualification) is needed to prove the machine’s ability to produce consistent BIs. This can add 6–12 months to project timelines.

- Skilled Workforce Demand: Operators must have expertise in microbiology, aseptic techniques, and advanced automation systems. Companies often invest in specialized training programs or partner with technical institutions.

- Cost-Benefit Analysis: While initial investment can exceed $1.5 million for a full-scale line, the long-term savings from reduced failures, increased throughput, and regulatory compliance make automation financially viable within 2–3 years.

Conclusion

Biological indicator assembly machines have transformed sterilization assurance from a manual, error-prone process into a highly precise, data-driven operation. As industries demand ever-greater reliability and traceability, these machines will continue to evolve, integrating cutting-edge technologies to meet the complex needs of modern healthcare, pharmaceuticals, and beyond. Balancing technological innovation with regulatory compliance and sustainability will be key to unlocking their full potential in the future of sterilization science.

# medical device #biological indicator #Automated Equipment for Biological Indicators