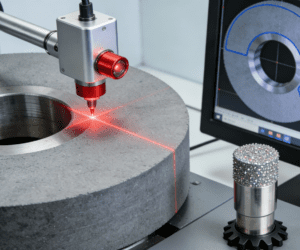

In fields such as precision machining, CNC precision machining and medical component manufacturing, precision grinding is an extremely crucial process, which is directly related to product accuracy and surface quality. To achieve ideal grinding results, optimizing process parameters is the key. Below is an in-depth exploration of knowledge in this regard.

Grinding Wheel Speed: Balancing Speed and Precision

Grinding wheel speed is one of the critical parameters in precision grinding. In intelligent machining, an appropriate grinding wheel speed can effectively improve grinding efficiency and surface quality. When the speed is too low, the material removal rate decreases significantly, leading to prolonged processing time and reduced production efficiency. Conversely, excessively high speed will induce problems like workpiece burns and deformation, undermining machining accuracy. For example, in medical component manufacturing, excessively high temperatures may alter the metallographic structure of parts and degrade their performance. Therefore, it is necessary to select the grinding wheel speed reasonably based on factors such as workpiece material and grinding wheel characteristics, so as to find the optimal balance between efficiency and precision.

Feed Rate: Minor Adjustments Leading to Significant Changes

The impact of feed rate on precision grinding should not be underestimated. In mold manufacturing, a smaller feed rate enables the grinding wheel to leave finer grinding marks on the workpiece surface, resulting in a smoother finish. However, an excessively small feed rate will greatly prolong processing time and reduce production efficiency. On the other hand, a larger feed rate can improve processing efficiency, but it may increase grinding force, leading to higher surface roughness of the workpiece and even dimensional deviations. Notably, when processing small metal sheets, the stability of feed rate is further guaranteed by Automatic feeding equipment for small metal sheets; this equipment can achieve continuous and uniform feeding according to the optimized feed rate parameters, avoiding feeding fluctuations caused by manual operation, thus ensuring consistent grinding marks on the surface of small metal sheets and further improving processing quality. Therefore, it is necessary to determine the appropriate feed rate through multiple tests according to specific processing requirements, so as to achieve the goal of high-efficiency and high-quality machining.

Grinding Depth: Precise Control Ensuring Quality

Grinding depth is also an important parameter affecting precision grinding. In CNC precision machining, an excessively large grinding depth will cause a sharp increase in grinding force and heat, which not only easily leads to defects such as workpiece surface burns and cracks, but also accelerates grinding wheel wear, affecting machining accuracy and wheel service life. Conversely, an excessively small grinding depth fails to give full play to the grinding performance of the wheel, resulting in low processing efficiency. Therefore, in the actual machining process, it is essential to precisely control the grinding depth according to the workpiece’s material, hardness and machining accuracy requirements, so as to ensure the stability of processing quality.

Cooling and Lubrication: An Indispensable Auxiliary Factor

Cooling and lubrication play a vital role in precision grinding. In CNC machining in Dongguan, favorable cooling and lubrication conditions can reduce grinding temperature, decrease friction between the grinding wheel and the workpiece, thereby improving machined surface quality and extending the service life of the grinding wheel. A suitable cooling fluid can also wash away grinding chips generated during the process in a timely manner, avoiding secondary scratches on the workpiece surface. Meanwhile, cooling and lubrication can reduce dimensional errors caused by workpiece thermal deformation, ensuring machining accuracy.

The optimization of precision grinding process parameters is a complex and delicate process that requires comprehensive consideration of multiple factors including grinding wheel speed, feed rate, grinding depth and cooling and lubrication. Only through continuous experiments and research to find the most suitable parameter combination can we achieve the processing goals of high efficiency, high precision and high quality in precision component manufacturing, and meet the stringent requirements of various fields for precision grinding.