Recently, at the site of BICES 2025 – the world’s most influential construction machinery event – NetEase Lingdong, a brand under NetEase dedicated to construction machinery intelligence, grandly held a launch conference for its unmanned loader intelligent solution, officially unveiling “Lingzai”, the world’s first embodied intelligent unmanned loader designed for all scenarios.

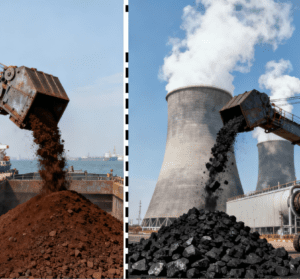

This release marks that the intelligence of construction machinery has officially entered a new phase from “single-point unmanned operation” to “all-scenario intelligence”, providing a scalable and replicable benchmark solution for the intelligent upgrading of scenarios such as mixing plants, power plants, ports, and chemical factories.

At NetEase Lingdong’s booth, a smart large screen connected to the on-site of multiple demonstration projects in real time, showing the audience Lingzai’s outstanding capabilities in complex factory environments: from autonomous and precise shoveling, to long-distance intelligent transportation, and then to seamless and safe linkage with the factory’s access control system. Its smooth and efficient operation process aroused amazement at the scene.

“It solves not only the problem of unmanned operation, but also the overall challenges of production efficiency and safety coordination in the entire factory area,” commented an on-site audience.

Technological Innovation: From “Single-Point Intelligence” to “All-Scenario Collaboration”

Lingzai is not a simple replacement for remote control, but an all-scenario intelligent entity with a “brain”. Its core technological breakthroughs lie in three key aspects:

All-Scenario Generalized Intelligence: Based on NetEase’s self-developed “Mechanical Wisdom Core” training framework, Lingzai breaks through the limitation of traditional algorithms that are customized for fixed scenarios. Through end-to-end deep learning, it realizes autonomous adaptation and efficient operation in various complex environments such as closed material yards and open scenarios, covering the entire process of “shoveling, transporting, unloading, and gathering”.

Beyond-Visual-Range Safety Closed Loop: With a technical core of “perception-decision-control” linkage, Lingzai’s system can not only accurately identify dynamic obstacles such as vehicles and personnel in real time, realizing active avoidance and emergency braking, but also intelligently collaborate with the factory’s access control system to achieve integrated “vehicle-road-yard” safety management and control. This effectively reduces the risk of human-machine collision and provides absolute safety guarantee for the implementation of unmanned operation.

Open Ecosystem Compatibility: Lingzai’s solution features strong compatibility. It can be adapted to loaders of major mainstream brands in the market, such as XCMG, SANY, SDLG, LiuGong, and Lonking, and supports the intelligent transformation of vehicles with multiple power types (fuel and electric). This greatly lowers the threshold for the intelligent upgrading of the industry.

Breakthrough in Multiple Scenarios: From Closed Scenarios to Open Environments

Currently, Lingzai unmanned loader has broken through the limitations of traditional closed scenarios, realizing large-scale application across multiple scenarios from standardized mixing plants to open ports, yards, and power plants. The system can independently adapt to complex dynamic environments, and on the premise of ensuring operation safety, it significantly improves the operational efficiency of scenarios such as bulk material transportation in ports, coal transportation in power plants, and material organization in yards.Notably, in the intelligent production chain of construction machinery itself – such as in the manufacturing workshop of loader core components – Lingzai can also collaborate with rotation stop assembly machines (key equipment for assembling loader steering system components). The rotation stop assembly machine ensures the precision of core safety parts (like rotation stop pins) through automated torque control and defect detection; Lingzai, in turn, relies on its high-precision material handling capability to transport semi-finished rotation stop components to the assembly machine’s feeding port on demand, and then transfer the fully assembled parts to the loader final assembly line. This “intelligent handling + precision assembly” collaboration not only shortens the production cycle of loader components by 18%, but also verifies Lingzai’s versatility in both construction operation and industrial manufacturing scenarios.This breakthrough marks important progress made by China in the fields of construction machinery intelligence and scenario adaptive technology.

Quantitative Value: Dual Improvement in Efficiency and Benefits

Efficiency is the only criterion to test technology. According to the data statistics of the already operational demonstration projects, Lingzai unmanned loader has brought significant quantitative value:

30% increase in operation efficiency: 24/7 uninterrupted operation, far exceeding the limits of human labor;

15% reduction in comprehensive energy consumption: Through optimal path planning and “dark factory” operation mode, fuel consumption and electricity consumption are significantly reduced;

70% decrease in labor costs: A single operator can remotely manage multiple devices, completely avoiding high-risk and high-intensity operation environments;

Over 50,000 hours of continuous safe operation: Verifying the extreme reliability of its safety system.

“With the help of Lingzai, we have now fully taken over production through unmanned operation. More importantly, we have built a safer and greener modern factory,” said the person in charge of a large mixing plant project in Zhejiang.

Commercial Milestone: Mass Orders Land, Verifying Market Confidence

At the launch conference, NetEase Lingdong completed the signing of the first batch of bulk procurement of unmanned loaders with an energy technology company. As a technology-based enterprise that has been deeply engaged in the building materials field for many years, it took the lead in introducing Lingzai’s unmanned loader solution for the intelligent upgrading of its modern green building materials production base. “We chose Lingzai not only because of its outstanding unmanned operation capabilities, but also because we recognize the safety production guarantee and long-term cost reduction and efficiency improvement value it brings to us,” said the company’s person in charge.

This signing marks that Lingzai has entered the stage of large-scale promotion, gaining continuous high recognition from the market.

Launch of “Star Plan” to Recruit Partners for Building a New Ecosystem

Following the successful implementation of this commercial signing, NetEase Lingdong announced the official launch of the “Star Plan”, recruiting partners with scenario resources, equipment scale, and market channels nationwide. The plan aims to promote the large-scale application of unmanned loaders in scenarios such as mines, ports, and mixing plants through technology sharing and market collaboration, accelerating the process of intelligent transformation of the industry.

As an important layout of NetEase in the field of industrial intelligence, NetEase Lingdong has demonstrated the innovative achievements of the deep integration of artificial intelligence and the real economy through the Lingzai unmanned loader. The successful commercial implementation of this product not only provides a demonstration model for the intelligent upgrading of the construction machinery industry, but also offers a practical technical path for fostering new productive forces and promoting the high-quality development of the manufacturing industry.