With the continuous development of industrial technology, precision manufacturing processes have become a core driving force for the advancement of high-end products. In industries such as medical devices, stage lighting and life sciences, the precision of components directly impacts product performance, safety and user experience. This is especially true for the production of medical device parts and precision components for stage lighting, where the importance of precision manufacturing processes cannot be overlooked. From a popular science perspective, this article analyzes in detail the improvements that precision manufacturing processes bring to these two fields.

What is Precision Manufacturing Process?

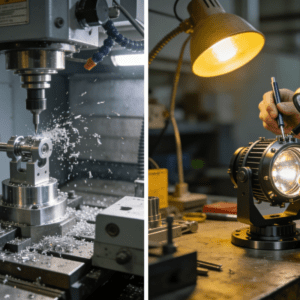

Precision manufacturing process refers to the process of processing raw materials into components that meet stringent standards in terms of dimensions, shape and surface quality through high-precision equipment and advanced processing technologies. It encompasses not only traditional machining, but also modern numerical control technology, laser processing, ultrasonic processing, precision mold manufacturing and micro-nano surface treatment.

Compared with general manufacturing processes, precision manufacturing places greater emphasis on error control and repeatability. For example, in the processing of medical device components, a micron-level deviation in a single part may affect the accuracy of the entire device; in precision components for stage lighting, a slight structural deviation can lead to beam offset or abnormal mechanical operation. Therefore, precision manufacturing not only requires advanced equipment, but also strict process flows and a highly skilled operating team.

How Precision Manufacturing Processes Upgrade Medical Device Components

Medical devices have extremely high requirements for the precision, durability and reliability of their components, as every part can directly affect diagnosis and treatment outcomes and even patient safety. Precision manufacturing processes have brought significant improvements to medical device components in the following aspects:

First, precision manufacturing significantly improves the machining accuracy of components. Modern medical devices such as surgical instruments, imaging equipment and laboratory analysis instruments have extremely strict dimensional requirements for their parts. Precision manufacturing processes can control machining errors at the micron level, ensuring a perfect fit between components and the entire device. This high-precision machining not only enhances the stability of the equipment and makes operations smoother, but also helps medical staff achieve more accurate diagnosis and treatment.

Second, precision manufacturing extends the service life of components. High-precision parts feature low friction, minimal wear and high resistance to deformation. For medical devices that require long-term continuous operation, precision manufacturing not only reduces equipment maintenance frequency and overall operating costs, but also lowers equipment failure rates with high-quality components, ensuring the normal operation of medical institutions.

Finally, precision manufacturing enhances equipment safety. In the medical industry, any minor deviation may lead to misdiagnosis or treatment risks. Precision manufacturing processes ensure that every part complies with strict standards, guaranteeing equipment safety and reliability from the source. This is why many high-end medical device manufacturers regard precision manufacturing capabilities as a key consideration when selecting suppliers.

How Precision Manufacturing Processes Upgrade Stage Lighting Components

Unlike medical devices, the components of stage lighting play a crucial role in the entertainment and performance industry. Precision components for stage lighting typically include optical brackets, gear mechanisms, slide rails and heat dissipation parts. Precision manufacturing processes have improved these components in several aspects:

First, precision manufacturing ensures the high precision of optical and mechanical structures. Stage lighting requires accurate beam control and smooth movement—slight deviations in components may affect lighting effects and even cause beam spot offset or motion stuttering. Precision manufacturing processes can control part dimensions within an extremely small tolerance range, thus ensuring that the optical and mechanical performance of lighting fixtures meets design standards.

Second, high-precision components reduce noise and failure rates. Stage lighting needs to operate continuously for long periods during performances. High-precision components feature tight fit, reduced friction and mechanical vibration, making the operation of lighting fixtures more stable and quiet, and minimizing the impact of sudden failures on performances. At the same time, it also extends the overall service life of lighting fixtures, providing stable support for performances and tours.

Finally, precision manufacturing processes enhance design freedom. High-precision machining enables the realization of more complex structures and miniaturized designs, making stage lighting lighter and more multifunctional. For example, some new types of stage lighting achieve adjustable light beams, multi-angle rotation and precise follow-spot effects through precision gears and micro-motors—all made possible by precision manufacturing technology.

The Driving Value of Precision Manufacturing Processes for the Entire Industry

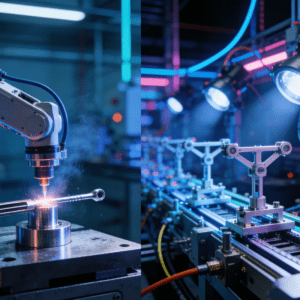

Precision manufacturing processes are not only valuable for medical devices and stage lighting, but their importance is increasingly prominent across the entire industrial sector. They not only improve product quality and performance, but also drive industrial technological upgrading and innovation. Through precision manufacturing, lighter, smaller and more efficient components can be produced, meeting the demands of modern industry for high-performance and high-reliability products.

In addition, precision manufacturing processes are equally important in the R&D phase. Designers and engineers can use precision machining to realize prototype verification and complex structure testing, thus iterating design schemes rapidly. This capability not only shortens product development cycles and reduces R&D costs, but also gives enterprises a stronger competitive edge in the market.

Conclusion

In summary, precision manufacturing process is not only a technical method, but also a key guarantee for improving the quality and performance of high-end products such as medical devices and stage lighting. For medical device components, it ensures high precision, reliability and safety of the equipment; for precision components of stage lighting, it guarantees optical accuracy, mechanical stability and design innovation capabilities.