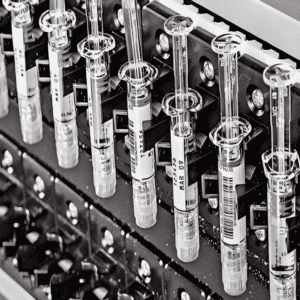

As the medical industry develops rapidly, the demand for high-quality syringes is growing, and strict requirements are put forward for syringe assembly precision, sterility and production efficiency. Standard assembly equipment can no longer meet the diverse needs of different medical enterprises. Ruizhi Intelligent Manufacturing focuses on high-precision non-standard automation solutions, and its High-Precision Non-Standard Syringe Automatic Assembly Equipment has become a core choice for medical device manufacturers, solving pain points such as low precision, poor adaptability and low efficiency in traditional assembly.

The Core Guarantee of Medical Syringe Quality

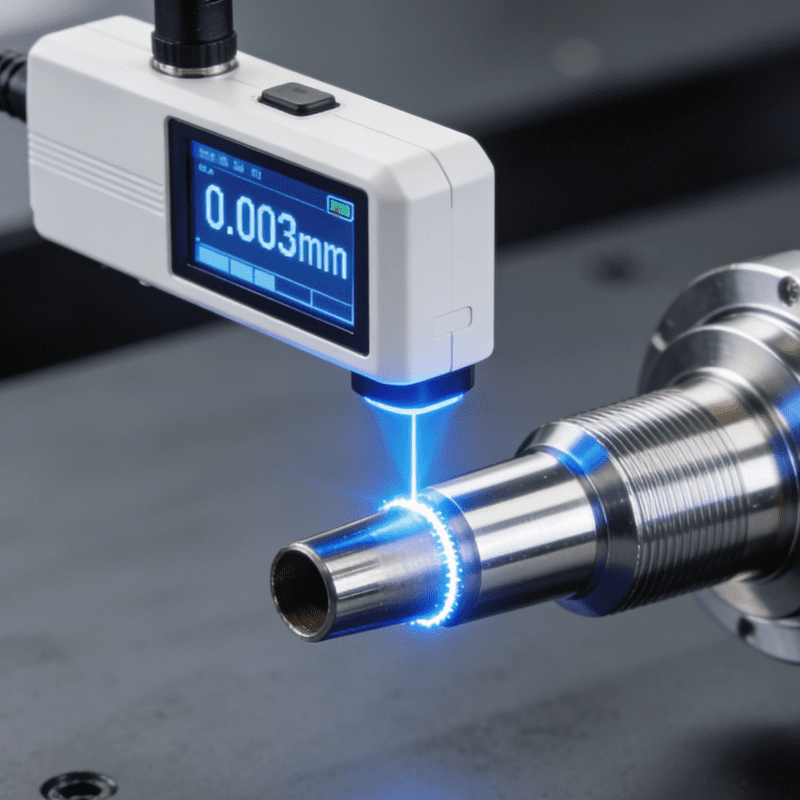

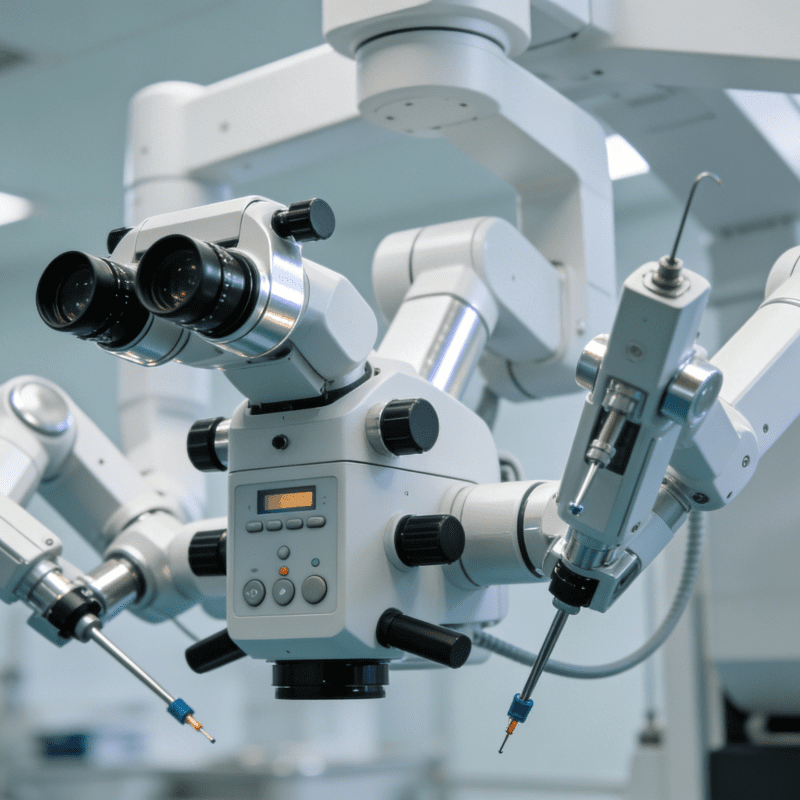

Medical syringes are directly related to patient safety, so assembly precision is the top priority. Our equipment adopts advanced servo control system and high-precision positioning technology, which can control the assembly error within ±0.1mm, fully meeting the ISO 7886-2:2020 international standard and GMP pharmaceutical production specifications. Equipped with an intelligent visual inspection system, it can automatically detect and eliminate unqualified products such as needle deviation and poor piston sealing, ensuring the consistency and safety of each syringe. Ruizhi Intelligent Manufacturing adheres to the concept of “precision first”, and each equipment has undergone strict debugging and testing before leaving the factory to provide reliable support for medical production.

Adapting to Diverse Production Needs

Different medical scenarios require syringes of various specifications, sizes and materials, which puts forward higher requirements for the adaptability of assembly equipment. As a professional non-standard automation manufacturer, Ruizhi Intelligent Manufacturing can provide personalized customization solutions according to customers’ actual needs. Whether it is insulin syringes, vaccine syringes or special-shaped syringes, whether the material is glass or plastic, our equipment can be flexibly adjusted in terms of assembly process, speed and module configuration to perfectly match the customer’s production line and avoid the waste caused by inconsistent equipment and production needs.

Empowering Cost Reduction and Efficiency Improvement

While ensuring precision and customization, our equipment also focuses on production efficiency and stability. It realizes fully automatic operation from component feeding, assembly, detection to finished product collection, replacing 5-10 manual positions, and the hourly output can reach up to 24,000 syringes. The modular design reduces equipment failure rate and maintenance cost, and the average maintenance cycle is extended by 30% compared with traditional equipment. Ruizhi Intelligent Manufacturing also provides one-stop after-sales service, including installation, commissioning and technical training, to ensure the long-term stable operation of equipment and help customers reduce production costs and enhance market competitiveness.

Ruizhi Intelligent Manufacturing is committed to using high-precision non-standard automation technology to help the medical industry upgrade. Our High-Precision Non-Standard Syringe Automatic Assembly Equipment integrates precision, customization and efficiency, creating more value for global medical device manufacturers.