In the cosmetic industry, lipstick production has increasingly strict requirements for assembly precision—small deviations in lipstick core positioning, cap fitting, or tube assembly can affect product appearance and user experience. Meanwhile, diverse lipstick styles (bullet-shaped, matte, retractable, etc.) make standard assembly equipment difficult to adapt. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing launches the High-Precision Non-Standard Lipstick Assembly Machine, integrating high precision and customized design to solve the core pain points of lipstick factories.

Ensure Perfect Assembly Quality

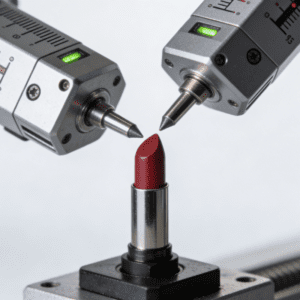

The core highlight of Ruizhi’s High-Precision Non-Standard Lipstick Assembly Machine is its micron-level assembly accuracy. Equipped with an intelligent PLC control system and high-precision sensors, it can accurately control the positioning error of lipstick cores within ±0.01mm, ensuring tight fitting between caps and tubes without looseness or deviation. It effectively avoids defects such as uneven lipstick core exposure, skewed caps, and scratches caused by manual assembly or low-precision equipment, greatly improving product qualification rate and reducing waste.

Adapt to Diverse Lipstick Styles

Ruizhi Intelligent Manufacturing focuses on non-standard automation, deeply understanding the diverse production needs of cosmetic factories. Our lipstick assembly machine supports full non-standard customization, which can be flexibly adjusted according to different lipstick tube diameters, lengths, core types, and assembly processes. Whether it is a small sample lipstick, a large-capacity retractable lipstick, or a special-shaped tube lipstick, our R&D team will tailor exclusive solutions to perfectly match your production line and realize one-machine multi-style assembly.

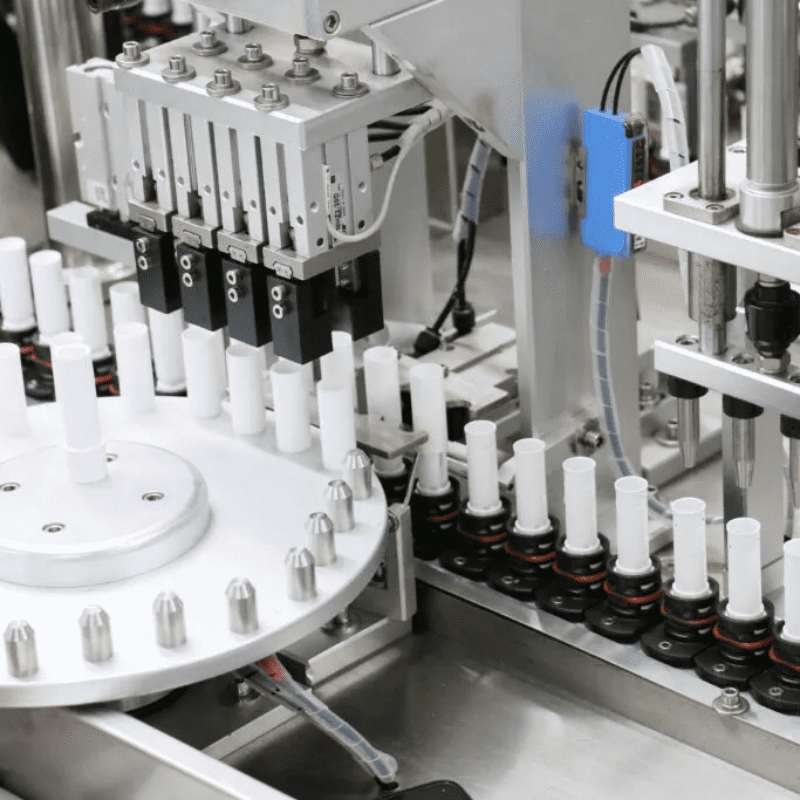

Empower Factory Productivity Upgrade

While ensuring high precision, the machine also achieves efficient and labor-saving production. It integrates automatic feeding, core installation, cap assembly, quality inspection, and blanking, with a production speed of 60-80 pieces per minute—3-4 times that of manual assembly. One machine can replace 6-8 manual workers, reducing labor costs by 40%-60% annually. The machine adopts wear-resistant and corrosion-resistant components, ensuring stable operation for a long time, low failure rate, and easy daily maintenance, saving time and cost for factories.

Ruizhi’s High-Precision Non-Standard Lipstick Assembly Machine perfectly combines precision, customization, and efficiency, becoming a core helper for lipstick factories to upgrade production. Choose Ruizhi Intelligent Manufacturing, and let professional non-standard automation technology help you improve product quality, reduce costs, and gain an advantage in the fierce market competition.

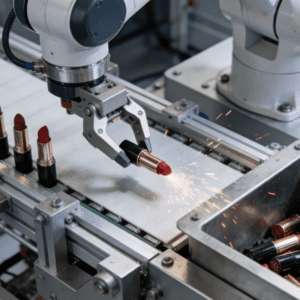

Assembly line for mass production by artificial intelligence

Robots for mass production assembly lines