Baby bottles, as core baby care products, have strict requirements for assembly hygiene, precision and consistency. Traditional manual assembly is plagued by low efficiency, high contamination risks, and inconsistent product quality, which can no longer meet the large-scale production needs of maternal and infant product manufacturers. Ruizhi Intelligent Manufacturing’s Fully Automatic Baby Bottle Assembly Machine integrates multiple processes with intelligent technology, creating a safe, efficient and stable production solution for the industry.

Improve Efficiency & Reduce Labor Costs

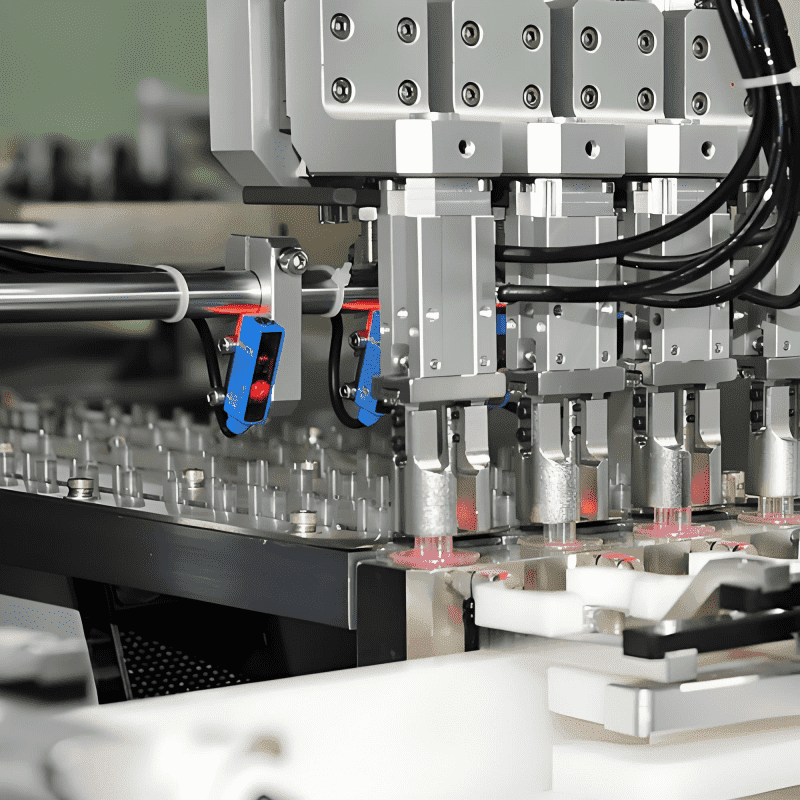

This machine integrates all core processes of baby bottle assembly, including bottle body feeding, nipple installation, cap locking, leak testing and finished product sorting. It eliminates manual transfer between single processes and manual contact with products, realizing one-stop automated production. Adopting a multi-station continuous operation design, it achieves a production capacity of 2000-2400 pieces per hour, 6-8 times that of manual assembly.

Only one operator is required for overall supervision and parameter adjustment, reducing labor costs by over 80% compared to traditional manual lines. The 24-hour stable continuous operation capability ensures timely delivery of large orders, perfectly adapting to the fast-paced production needs of maternal and infant product brands.

Safeguard Product Safety

Equipped with advanced PLC control system and AI visual positioning technology, the machine achieves assembly precision within ±0.03mm, ensuring tight fit between nipple and bottle body, and avoiding leaks. The key components are made of food-grade stainless steel, which is corrosion-resistant, easy to clean and meets the hygiene standards of the maternal and infant industry.

The built-in automatic leak testing unit detects each finished bottle with high pressure, automatically sorting out unqualified products with leaks or loose caps. This pushes the finished product qualification rate to over 99.8%, effectively avoiding potential safety hazards caused by assembly errors and protecting brand reputation.

Adapt to Diverse Product Specifications

As a professional non-standard automation manufacturer, Ruizhi Intelligent Manufacturing focuses on tailoring solutions to meet customers’ diverse needs. The machine can be flexibly adjusted for different baby bottle specifications, including various bottle diameters, capacities, nipple types and cap styles.

The parameter memory function shortens product changeover time to within 5 minutes, efficiently responding to small-batch and multi-style production demands. We provide one-stop services from demand analysis and prototype customization to on-site commissioning and after-sales maintenance, paired with a 2-year warranty and 48-hour online technical support, fully solving production worries for customers.

Ruizhi’s Fully Automatic Baby Bottle Assembly Machine redefines the production standard of baby bottles, helping enterprises achieve cost reduction, efficiency improvement and safety upgrade in the highly demanding maternal and infant market.