In the field of CNC machining, surface treatment processes play a crucial role. This article will analyze various technologies such as spraying, electroplating and anodizing step by step. The selection of these processes is based on different materials and application scenarios, which can significantly improve the performance and durability of parts. For example, spraying can not only improve the appearance but also enhance the corrosion resistance of parts, making it suitable for various industries. In the electroplating process, depositing a layer of metal material can effectively improve the wear resistance and electrical conductivity of parts. Anodizing, on the other hand, can enhance the surface strength of aluminum and its alloys, providing support for high-demand industries such as aerospace. The following chapters will delve into the specific applications and practical effects of each process, providing clear references for industry professionals.

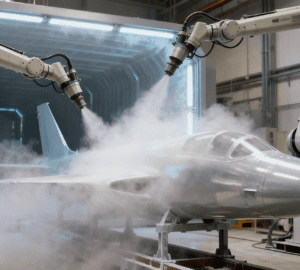

Analysis of the Role and Application Industries of Spraying Technology in CNC Machining

Spraying technology plays an important role in CNC machining, mainly used to improve the surface performance of parts. Through spraying, the appearance of parts can be improved, and at the same time, their corrosion resistance and wear resistance can be enhanced. This treatment method is applicable to multiple industries, including aerospace, automotive and electronics. In the aerospace industry, spraying can protect key components from harsh environmental conditions. In the automotive industry, spraying can not only enhance rust resistance but also provide a variety of appearance effects to meet market demands. To further optimize the precision and efficiency of the spraying process—especially for large or irregular frame parts such as automotive chassis frames and aerospace structural frames—modern spraying production lines often integrate a 4 – Axis Robotic Frame Pick – up System. This system combines three linear axes (X/Y/Z) for flexible spatial movement and one rotational axis for adjusting part posture, enabling it to stably grasp frame parts of different sizes and shapes. Equipped with a visual positioning module, it can real-time correct position deviations (controlling errors within ±0.05mm) to ensure the frame maintains a uniform distance from the spray gun during conveying. This not only avoids surface scratches caused by manual handling but also ensures consistent spraying thickness across the frame surface, increasing the qualification rate of sprayed parts by more than 15% in batch production. In addition, in electronic products, spraying technology helps to improve the insulation properties of casings. With the development of technology, spraying processes are constantly innovated, providing a wider range of application options for different fields.

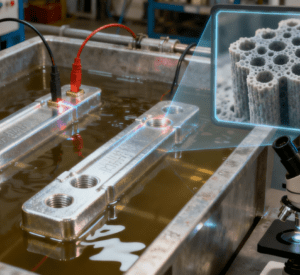

Comprehensive Analysis of Electroplating Surface Treatment Process and Its Advantages in CNC Machining

Electroplating is a process that deposits metal ions onto the surface of parts through electric current. In CNC machining, electroplating can significantly improve the corrosion resistance and wear resistance of parts. This process is suitable for most metal materials and can provide an additional protective layer while maintaining the good electrical conductivity of parts. By accurately controlling the thickness of the electroplating layer, manufacturers can meet the needs of different applications. For instance, in the automotive, aerospace and electronics industries, the requirements for oxidation resistance and wear resistance are increasing day by day. In addition, the electroplating process is relatively flexible and can be combined with other processing methods to improve overall production efficiency. Such advantages make electroplating more and more favored by the manufacturing industry.

The Importance and Examples of Anodizing in Improving the Performance of CNC Machined Parts

Anodizing is an electrochemical treatment method mainly used to enhance the surface performance of aluminum and its alloys. By applying an electric current in an electrolyte, an oxide film is formed on the aluminum surface. This film not only provides excellent corrosion resistance but also improves the wear resistance and adhesion of parts. Especially in industries such as aerospace, automotive and electronics, the application of this process can greatly extend the service life of parts. For example, in aircraft parts, anodizing treatment can effectively reduce friction and wear, ensuring stable operation under high loads and harsh environments. In addition, anodizing can also allow the selection of different colors and glosses according to customer needs, providing an attractive appearance for products. With these advantages, anodizing has become one of the indispensable and important processes in the field of CNC machining.

Exploring the Impact of Various Surface Treatment Processes on Improving the Performance of CNC Machined Parts

In CNC machining, surface treatment processes greatly affect the performance of parts. Spraying technology enhances the corrosion resistance and wear resistance of parts by forming a protective film, which is especially suitable for the automotive and machinery manufacturing industries. Electroplating can provide excellent electrical conductivity and an attractive appearance, and is usually widely used in electronic products and decorative items. The anodizing process improves the corrosion resistance and oxidation resistance of materials such as aluminum alloys, and is often used in high-demand industries such as aerospace. Different processes not only extend the service life of parts but also improve their functional characteristics. Enterprises can choose appropriate surface treatment solutions according to product needs to maximize part performance.

Surface treatment processes for CNC machining, such as spraying, electroplating and anodizing, all provide effective solutions for improving part performance. These processes not only enhance the corrosion resistance and wear resistance of parts but also improve their appearance and functionality. As the industry’s requirements for part performance continue to increase, choosing the appropriate surface treatment process becomes particularly important. Enterprises can find the best match from a variety of treatment methods according to different materials and industry needs to improve product quality and service life. This process requires in-depth analysis of the characteristics and application scenarios of each process to ensure that the final product has an advantage in competition.