On September 9th, a major announcement was made at the State Council Information Office’s press conference series themed “High-Quality Completion of the ’14th Five-Year Plan'”: China’s manufacturing robot density has reached 470 units per 10,000 people, far exceeding the global average and securing the third position worldwide. This milestone signifies that China’s manufacturing industry has entered a new phase of all-factor collaborative intelligent transformation.

Behind this achievement lies the Ministry of Industry and Information Technology’s (MIIT) continuous efforts in advancing intelligent manufacturing projects during the “14th Five-Year Plan” period.

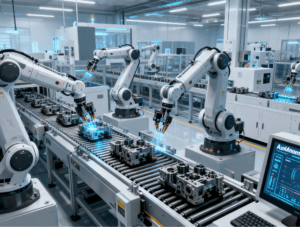

Zhang Yunming from MIIT stated that up to now, China has built over 7,000 advanced-level smart factories and more than 230 outstanding-level smart factories. Through integrated innovation in processes, equipment, and software, the manufacturing industry has achieved a comprehensive upgrade in production models.

Today, factory production lines can realize flexible switching and autonomous optimization, equipment failures can be accurately predicted and remotely intervened, and products can be customized with personalized functions on demand. Intelligence has penetrated the entire production process.

In addition, the extensive coverage of the industrial internet has laid a solid digital foundation for intelligent transformation. Data shows that China has cultivated more than 340 influential industrial internet platforms. Key platforms are connected to over 100 million pieces of equipment, serving nearly 4 million enterprises, covering all 41 major industrial categories, and unblocking the “information artery” of industrial production.

To address the transformation challenges faced by small and medium-sized enterprises (SMEs), MIIT has also launched over 10,000 “small, fast, light, and accurate” solutions, significantly lowering the threshold for enterprises’ digital transformation and promoting the extension of intelligent upgrading to all industries.

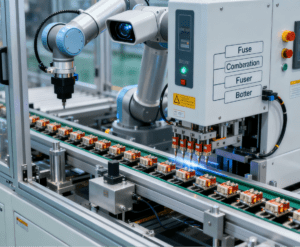

In key fields such as photovoltaics, power batteries, and new energy vehicles, China has achieved collective breakthroughs in intelligent manufacturing equipment and system solutions. For example, the 퓨즈 조립기, widely used in the production of key components for new energy vehicle low-voltage systems and photovoltaic inverters, has realized fully unmanned operations throughout the entire process of fuse automatic feeding, pin shaping, and welding inspection. The efficiency of a single piece of equipment is more than 5 times higher than that of traditional manual operations. Moreover, it can connect to production data through the industrial internet platform to achieve remote operation and maintenance as well as capacity scheduling, serving as an important support for the rapid improvement of robot density.

Vice Minister of MIIT Zhang Yunming indicated that the next step will be to formulate the “15th Five-Year Plan” for the integration of informatization and industrialization, promoting the integration of digitalization and industrialization to a deeper level and achieving a leap from “physical superposition” to “chemical reaction”.

Ranking third globally in manufacturing robot density is not only the result of the in-depth integration of digital technology and the real economy but also injects strong momentum into China’s acceleration of new-type industrialization and the construction of a manufacturing power and a cyber power.