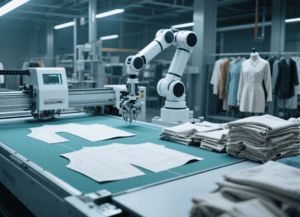

유연 제조에서 로봇 및 자동화 장비의 장점과 응용 분야에 관하여

제조업 분야에서 점점 더 치열해지는 글로벌 경쟁 속에서 유연 생산은 새로운 생산 모델로서 점차 중요한 방식으로 부상하고 있습니다.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

제조업 분야에서 점점 더 치열해지는 글로벌 경쟁 속에서 유연 생산은 새로운 생산 모델로서 점차 중요한 방식으로 부상하고 있습니다.

전통적인 제조업에서는 "종이보다 못한 이익"이 많은 기업에게 골칫거리입니다. 생산 낭비는 비용 급증과 시장 대응 지연으로 이어집니다.

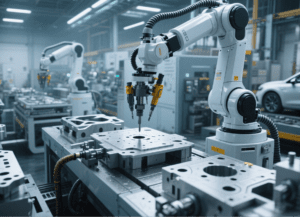

금속 가공 분야에서 굽힘 공정 자동화는 오랫동안 중소기업의 골칫거리였습니다. 기존 자동화 장비는

In recent years, the kitchen and bath industry has faced challenges such as a shrinking real estate market, rising raw material prices, and intensified fluctuations

In recent years, China has accelerated the in-depth integration of artificial intelligence and manufacturing, promoting the construction of a number of digital workshops and smart

1, Introduction to Sanitary Ware Products With the improvement of people’s living standards and the change of consumption concepts, people’s requirements for the home environment

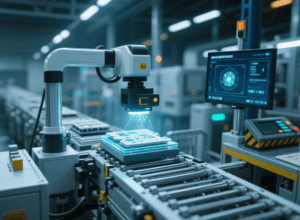

In the fast-paced world of electronics manufacturing, where miniaturization, precision, and speed define success, the Automated Loading Assembly Machine for Electronic Components has emerged as a transformative

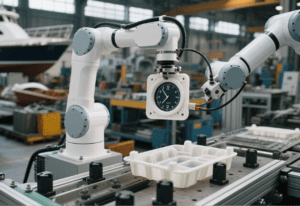

In the realm of modern manufacturing, where precision, speed, and scalability define market leadership, the Injection Molded Parts Automated Assembly System with Auto-Loading stands as a cornerstone

In the intricate chain of manufacturing, where precision and efficiency determine competitiveness, Automatic Injection – Molded Part Feeding And Assembly stands as a critical bridge between raw

In the relentless rhythm of modern industry, where consumer demands shift overnight and supply chains twist like rivers, FlexibleAutomation has emerged as the compass guiding manufacturers through

In the intricate landscape of modern manufacturing, where products range from micro-sized medical implants to large-scale aerospace components, a one-size-fits-all approach to assembly is no