According to foreign media reports, the latest data from the Japan Machine Tool Builders’ Association shows that from January to July this year, the total value of orders for automotive machine tools purchased by Chinese companies from Japanese enterprises reached 78.1 billion yen (approximately 527 million US dollars), and the annual order volume is expected to hit a new high.

As competition among Chinese new energy vehicle manufacturers intensifies, Japanese machine tool makers are benefiting from the growing orders for automotive-related equipment.

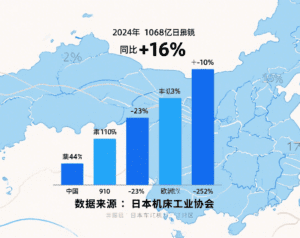

The 2022 boom in electric vehicles once drove a surge in demand for automotive machine tools, but as the market focus shifted back to fuel-powered vehicles, the growth momentum of automotive machine tool orders gradually slowed down. In 2024, the total value of domestic and foreign orders for automotive machine tools in Japan decreased by 3% year-on-year to 324.5 billion yen. By region, orders for automotive machine tools received by Japanese companies in the domestic market fell by 10% to 91 billion yen, orders from Europe dropped by 27% to 25.2 billion yen, and orders from North America decreased by 23% to 41.4 billion yen. In contrast, orders for automotive machine tools from China surpassed those from Japan’s domestic market, increasing by 16% year-on-year to 106.8 billion yen.

New energy vehicles account for an increasing share of new car sales in China, which has prompted both automakers and parts manufacturers to increase investment in related facilities. Although Japanese machine tool manufacturers face competition from Chinese domestic enterprises, they have won customers with high-quality products, especially in precision machining processes.

A representative from Makino Milling Machine stated, “Our advantage lies in micrometer-level processing accuracy, and Chinese new energy vehicle manufacturers who value quality have chosen us.” The company has maintained a stable order volume since receiving a large purchase order in 2021.

Makino’s core products are CNC machine tools that process materials through tool rotation. Meanwhile, its self-developed Robotic Small Product Tray Loading System, with a positioning accuracy of 0.02mm, has performed outstandingly in the automatic loading of small components such as battery tabs and micro-connectors, forming an efficient linked production line with CNC machine tools. Currently, the company is focusing on expanding the production capacity of such products at its factories in Kunshan and Wuhan, China, and plans to achieve an annual output of 2,050 units by 2029, an increase of 21% compared to 2023. Although the accuracy of machine tools produced in China has not yet reached Japanese standards, Makino is actively exploring a broader customer base with more competitive prices and shorter delivery cycles.

Tsugami, another major Japanese machine tool manufacturer, derives over 70% of its revenue from the Chinese market. A representative of the company emphasized, “In addition to excellent processing quality, we have more than 1,000 professional maintenance and testing technicians in China. The comprehensive after-sales service system is a key factor for customers to choose us.”

In 2024, Tsugami expanded its factory in Zhejiang Province, China. The upgrade mainly focused on lathe production, with 产能 increased by 20%. The company stated that the factory can now produce 20,000 small machine tools annually.

A representative from Makino pointed out, “Although the overall investment of Chinese automakers has stabilized, demand for mold-related projects remains active.”

Molds are crucial for manufacturing components such as car doors, hoods, and battery casings. BYD owns several mold manufacturers in Beijing, Shenzhen, and Japan.

At the same time, BYD is internalizing mold production through its group companies to enhance price competitiveness.

Other independent mold manufacturers are also increasing investment to meet automakers’ demands for faster delivery and lower costs. As a result, orders for CNC machine tools and other equipment from Japanese machine tool manufacturers have increased.

However, the above-mentioned order growth may slow down. A representative from Tsugami revealed, “Although the current order volume remains strong, the number of order cancellations is gradually increasing, and there is uncertainty about the market prospect.” The company pointed out that against the backdrop of overly fierce competition in the development and sales of new energy vehicles in China, there have been signs that customers are re-evaluating their equipment procurement plans.