In the vast landscape of modern manufacturing, CNC (Computer Numerical Control) machining acts like a key, unlocking the door to the world of precision manufacturing. This technology, which integrates advanced computer technology with the essence of traditional mechanical machining, is spearheading the transformation and development of the manufacturing industry with its unique features and extensive application scope.

CNC Machining: Definition and Working Principle

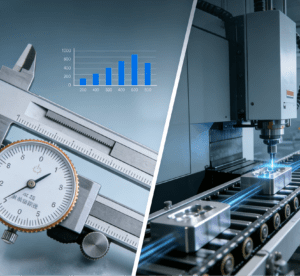

CNC machining, or Computer Numerical Control machining in full, is a technology that utilizes pre-written computer programs to control machine tools for automated machining operations. Its fundamental principle is that pre-compiled numerical control programs guide the cutting tools on machine tools to perform machining operations such as cutting, drilling, and milling on workpieces in accordance with preset paths and parameters. During this process, the computer monitors the machining status in real time via sensors, ensuring that every minute movement achieves extremely high precision and stability.

Advantages of CNC Machining

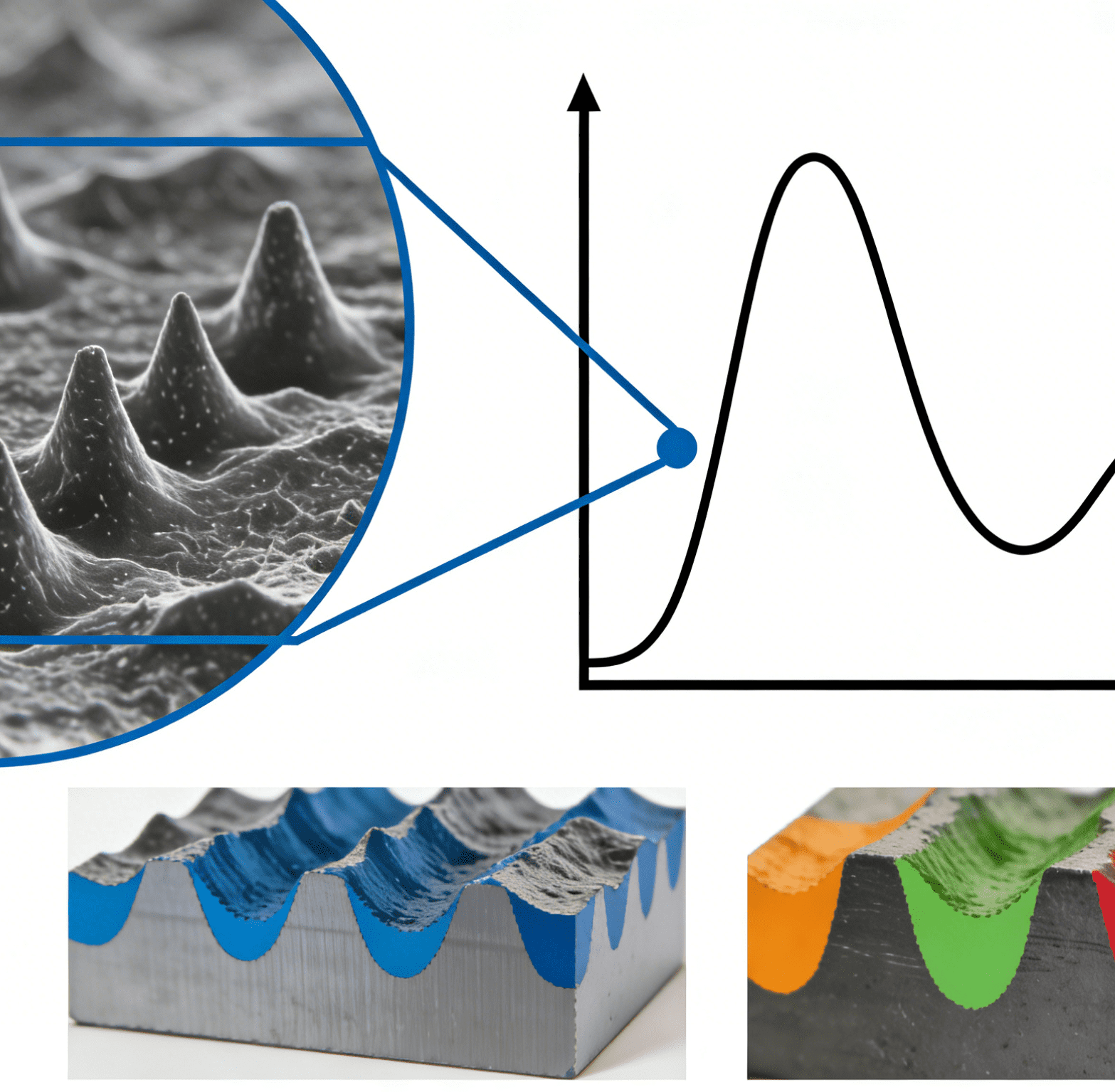

High Precision: The most prominent feature of CNC machining lies in its high-precision machining capability. Benefiting from the accuracy of computer control and the high stability of machine tools, CNC machining can achieve micron-level machining precision, satisfying the stringent requirements for dimensions and shapes in precision manufacturing.

High Efficiency: Compared with traditional manual or mechanical machining, CNC machining can significantly boost production efficiency. Under program control, machine tools can carry out continuous and stable machining, reducing manual intervention and waiting time, thereby shortening the production cycle.

Flexibility: The flexibility of CNC machining is reflected in its ability to process parts with diverse complex shapes and structures. By modifying programs, machine tools can quickly adapt to the production requirements of different products, cutting down the replacement costs of molds and fixtures.

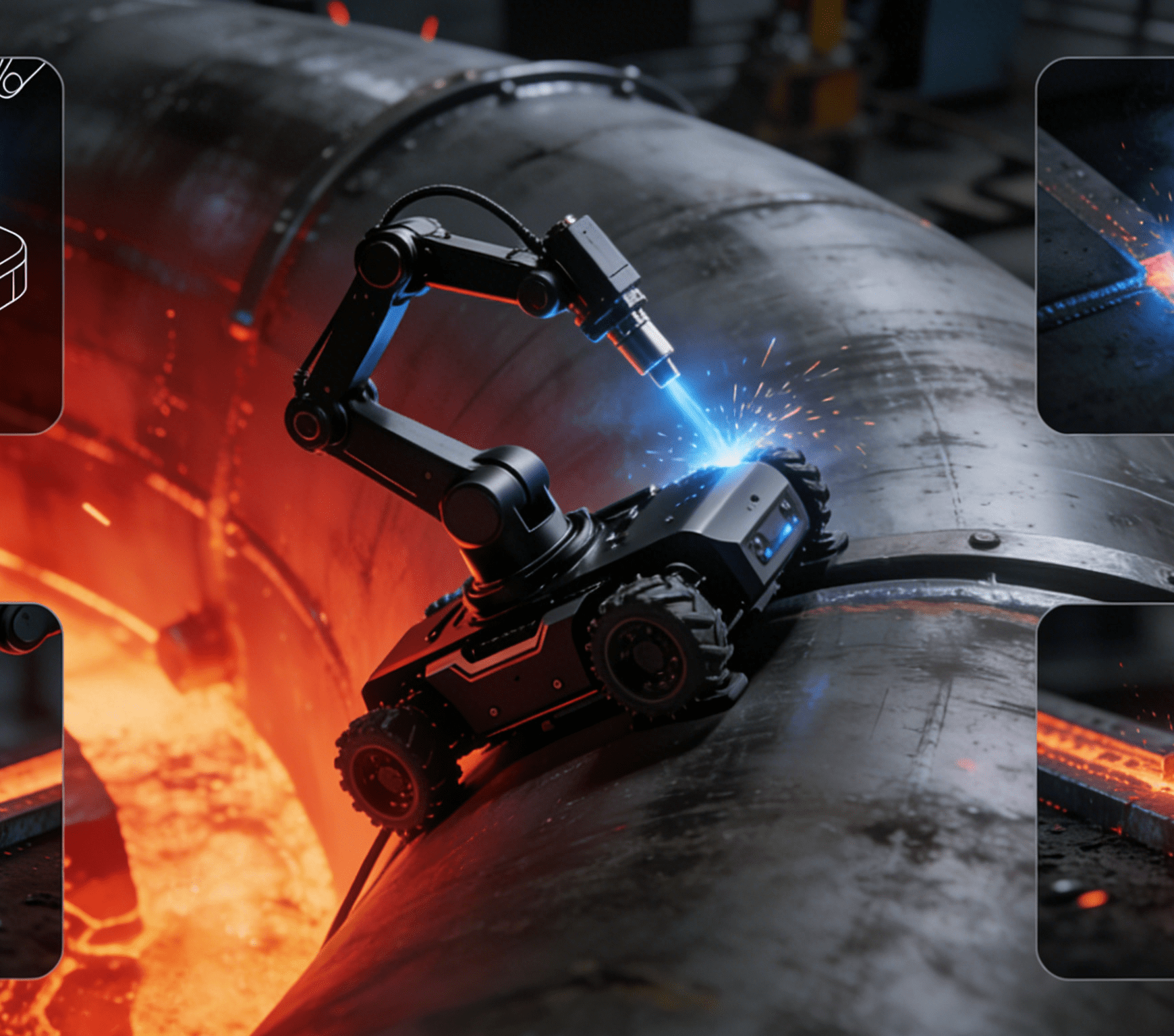

Automation and Intelligence: With the advancement of technology, CNC machining is gradually moving towards automation and intelligence. By incorporating technologies such as artificial intelligence and the Internet of Things, CNC machine tools can realize functions including remote monitoring, fault early warning, and automatic adjustment, further improving production efficiency and equipment utilization rate.

Application Fields of CNC Machining

CNC machining technology is widely applied in numerous fields such as aerospace, automobile manufacturing, electronic equipment, and medical devices. In the aerospace sector, CNC machining is used to produce high-precision components like engine blades and airframe structures; in automobile manufacturing, it is employed to fabricate key parts including engine blocks and crankshafts; in the fields of electronic equipment and medical devices, CNC machining also plays a vital role in manufacturing precision circuit boards, casings, and medical instruments. Even in the production of Automatic spring equipment—core equipment for manufacturing springs used in automotive suspension systems, electronic switch components, and industrial machinery—CNC machining is indispensable. It is used to process high-precision forming molds, core transmission shafts, and positioning clamps for automatic spring coiling machines and spring grinding machines. The micron-level precision of CNC machining ensures that the springs produced by the equipment have uniform wire diameter, consistent pitch, and stable elasticity, meeting the strict quality standards of various industries.

With the transformation, upgrading, and intelligent development of the manufacturing industry, CNC machining technology will embrace broader development prospects. On the one hand, CNC machining will place greater emphasis on environmental protection and sustainable development, reducing environmental pollution and resource waste by optimizing cutting processes and improving energy utilization efficiency. On the other hand, CNC machining will be deeply integrated with technologies such as artificial intelligence and big data, realizing a more intelligent and efficient machining process.

Getting to know CNC machining for the first time, we seem to step into a world full of infinite possibilities. Here, precision manufacturing is no longer a distant dream but an accessible reality. With the continuous progress of technology and the expansion of application fields, CNC machining will continue to lead the transformation and development of the manufacturing industry, creating a better future for us. Let us join hands to open the door to precision manufacturing and explore a new chapter in the manufacturing industry!