In the field of precision engineering, CNC (Computer Numerical Control) is a revolutionary technology. So, what exactly is CNC in precision engineering?

Core Definition of CNC: The “Intelligent Craftsman” in Precision Engineering

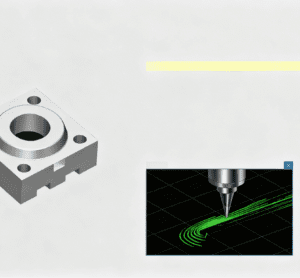

CNC is a technical method that precisely controls machine tool movement and machining processes through pre-programmed computer programs. In precision engineering, it is like an extremely accurate “intelligent craftsman”. Traditional mechanical processing relies on manual operation of machine tools, and the machining accuracy is largely limited by the operator’s skills and experience, making it difficult to achieve a high level of consistency and ultra-precise dimensional control. The emergence of CNC technology has changed this situation.

Applications and Core Advantages of CNC in Precision Engineering

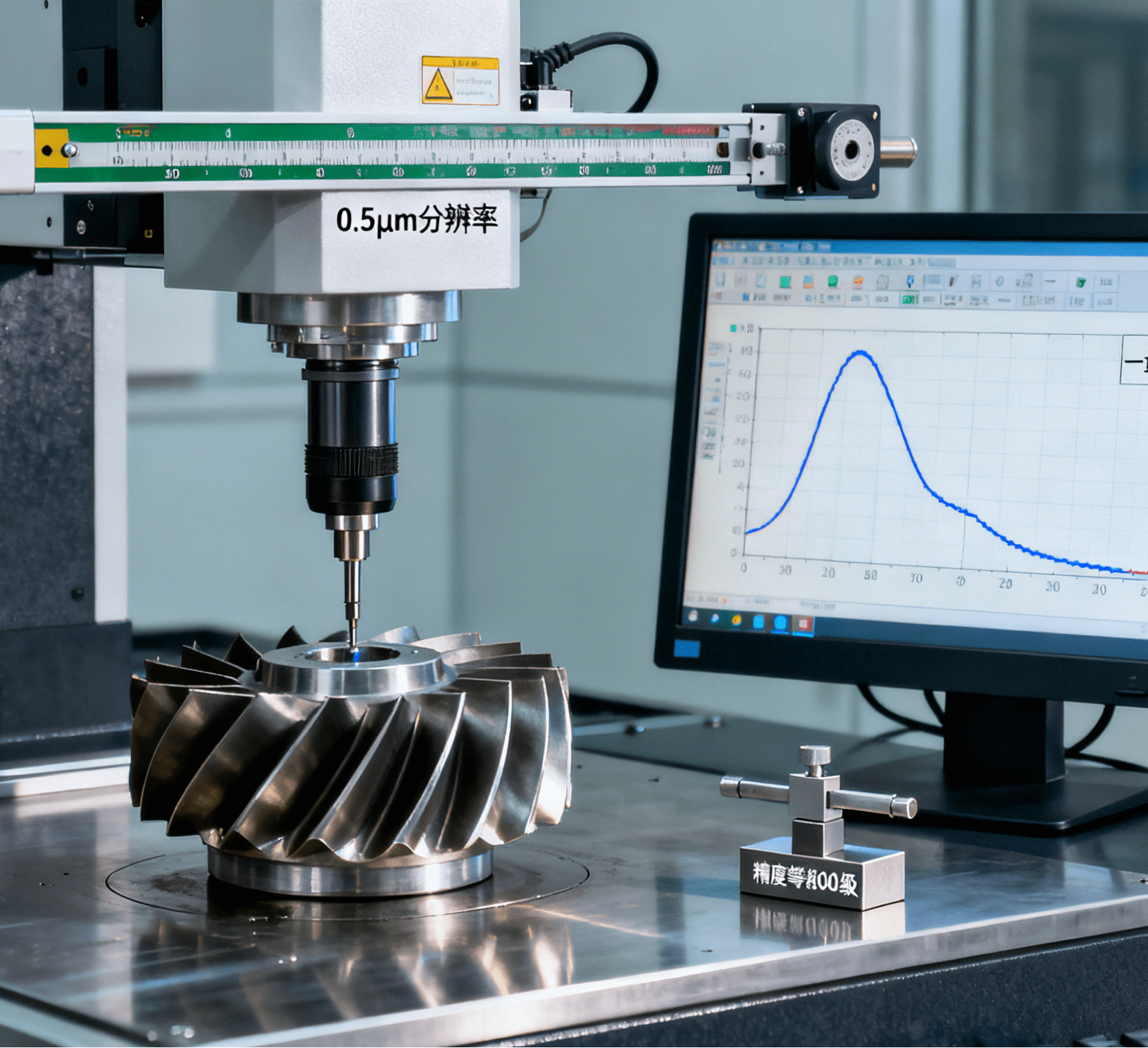

In practical applications of precision engineering, CNC machine tools can generate detailed machining instruction codes using professional software based on designed 3D models or engineering drawings. These codes include key parameters such as tool path planning, cutting speed, and feed rate. For example, when manufacturing high-end optical lens molds, CNC machine tools can perform milling, grinding, and other machining operations on mold materials in accordance with extremely precise instructions, ensuring that the surface accuracy of the mold reaches the micron or even nanometer level. This thereby guarantees that the produced optical lenses have excellent optical performance, such as precise focal length and extremely low aberration. Another typical application lies in the manufacturing of injection molds and subsequent assembly: CNC machine tools first process injection mold cavities with high precision to ensure the dimensional accuracy of injection molded parts, and then the 自動ローディング機能付き射出成形部品自動組立システム, which is highly compatible with CNC machining accuracy, can automatically load the precision injection molded parts, complete assembly operations such as fitting and fastening with micron-level positioning, and directly convert the high-precision machining results of CNC into assembled product quality.

CNC technology has significant advantages in precision engineering. Its machining accuracy is extremely high, which can easily meet the strict requirements for component precision in industries such as aerospace, medical equipment, and electronic chip manufacturing. It also has high repeatability and stability—no matter how many identical parts are processed, it can ensure a high degree of quality consistency. At the same time, CNC can handle extremely complex geometric shapes, and some special-shaped structures that are difficult to complete with traditional machining methods can be accurately realized by it.

Enterprise Practice: Airey Precision Machinery’s Implementation of CNC Technology

Airey Precision Machinery has performed outstandingly in the application of CNC in precision engineering. The company has a professional team composed of senior engineers who are proficient in CNC programming technology. They can write optimized machining programs for different precision engineering tasks to maximize the performance of CNC machine tools. The company is equipped with a series of advanced CNC machining equipment, which adopt high-precision spindles, advanced positioning systems, and high-resolution sensors to ensure precise positioning and accurate cutting during the machining process.

During the machining process, Airey Precision Machinery strictly adheres to the international standard quality management system. Every link is handled meticulously, from the strict screening of raw materials, to real-time monitoring and adjustment during machining, and to the precision inspection of finished products. Whether it is small precision mechanical parts or large high-precision structural parts, Airey Precision Machinery can rely on its profound expertise in CNC technology to provide high-quality and highly reliable products for the precision engineering field. It has established a good reputation in the industry and effectively promoted the technological progress and development of the precision engineering industry.

In precision engineering, CNC is a key technology to achieve high-precision and high-quality machining. Airey Precision Machinery is an excellent practitioner in this technical field. Through continuous innovation and improvement, it continuously provides precise and reliable machining support for various fields of precision engineering, helping precision engineering reach a higher level of development.