In industrial production and equipment maintenance scenarios, handling irregular-shaped metal parts has always been a “persistent challenge”—ranging from waste engine irregular casings in automobile dismantling, worn eccentric gears in machine tool maintenance, to curved connectors in the aerospace field. Due to their lack of fixed contours, large size variations, and frequent rust or adhesion, traditional handling methods are either inefficient or high-risk. The emergence of the Robotic Irregular-Shaped Metal Part Removal System (hereinafter referred to as the “Irregular Metal Handling Robot System”)—with its technical combination of “perception + flexible execution”—has become a core solution to address this pain point.

Industry Pain Points: Why Does Irregular Metal Part Handling “Stump Experts”?

In industries with concentrated demand for irregular metal part handling, the limitations of traditional methods have long been prominent, even becoming key bottlenecks restricting efficiency and safety:

Manual Handling: Low Efficiency and High Risk

For heavy irregular parts weighing over 50kg (such as ship deck connectors), manual handling requires the assistance of cranes, with a single part taking more than 1 hour to disassemble. Moreover, the sharp edges of parts easily cause scratches. For thin-walled irregular parts with high precision requirements (such as aero-engine blades), uneven manual force application often leads to part deformation, with a scrap rate as high as 15%-20%.

Conventional Robotic Arms: “Inaccurate Recognition and Unreliable Grasping”

Traditional robotic arms rely on preset programs and fixed fixtures. When faced with metal parts with irregular contours, they can neither identify the actual shape and positional deviation of the parts (such as dimensional deformation caused by rust) nor adapt to surfaces with different curvatures. For example, using a flat fixture to grasp a curved casing either results in insufficient clamping force (causing the part to fall) or excessive pressure (crushing the part).

Batch Handling: Insufficient Flexibility and High Changeover Costs

In scenarios such as automobile dismantling and waste equipment recycling, a single production line needs to handle dozens of types of irregular parts. Conventional equipment requires fixture replacement and reprogramming, with a single changeover taking 2-4 hours—completely unable to meet the “multi-variety, small-batch” handling needs.

Behind these pain points lies an inherent contradiction between “irregular shapes” and “rigid handling methods.” The core value of the Irregular Metal Handling Robot System is to break this contradiction through “flexible perception + adaptive execution.”

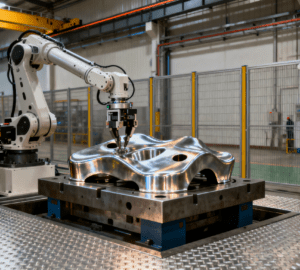

Technical Breakdown: The “Four Core Modules” of the Irregular Metal Handling Robot System

Unlike a single robotic device, this system is an integrated “perception-decision-execution-control” solution. Four core modules jointly support its precise handling of irregular metal parts:

Multi-Axis Flexible Robot Body: The “Flexible Torso”

The system typically uses a 6-axis or 7-axis collaborative robot as its main body. Compared with traditional 3-axis/4-axis robotic arms, the multi-axis design enables a repeat positioning accuracy of ±0.02mm and a 360° movement coverage range. For example, when handling eccentric bolts on an engine block, the robot can adjust the wrist angle to match the inclined installation angle of the bolts, avoiding thread damage caused by forced disassembly. For some heavy-duty scenarios (such as ship part handling), a rail-mounted mobile base is used, expanding the robot’s working radius to over 10 meters to meet the handling needs of large irregular parts.

3D Vision + Force Control Dual-Mode Perception: The “Sharp Eyes and Tactile Sense”

3D Vision Positioning: Solving the “Inaccurate Recognition” Problem

The system is equipped with a structured light or LiDAR 3D camera, which can scan the 3D contour of irregular parts within a range of 0.5-3 meters, generate a point cloud model, and compare it with preset drawings. It automatically identifies the actual positional deviation, rusted areas, or adhered parts of the component. For instance, when handling gears of waste machine tools, 3D vision can accurately locate the meshing gap between the gear and the shaft, avoiding jamming caused by blind disassembly.

Force Control Sensors: Solving the “Unreliable Grasping and Easy Damage” Problem

The end of the robot integrates a force control module with an accuracy of ±0.1N, which provides real-time force feedback during grasping or disassembly. When grasping thin-walled parts, the force control system limits the clamping force to a safe range of 50-100N. When disassembling rusted bolts, if the torque exceeds a preset threshold (e.g., 200N·m), the system automatically pauses and adjusts the angle to prevent bolt breakage.

Adaptive End Effector: The “Deformable Gripper”

The end effector—rather than a traditional fixed fixture—is the “key weapon” for the system to adapt to irregular parts. Common designs include:

Pneumatic Multi-Claw Gripper: Equipped with 3-6 independently adjustable claws, the opening angle of the claws is controlled by air pressure, allowing them to fit the surfaces of parts with different shapes (circular, square, curved, etc.). For example, when grasping irregular steel pipes, the claws automatically adjust to a “three-point support” to prevent the pipe from rolling.

Magnetic + Vacuum Composite Gripper: For ferromagnetic materials (such as carbon steel parts), the magnetic module provides stable adsorption force; for non-magnetic or thin-walled parts (such as aluminum alloy casings), vacuum suction cups supplement adsorption, ensuring double protection for grasping stability.

Customized Disassembly Tools: For connecting irregular parts (such as bolts and rivets), the effector can integrate an electric wrench or hydraulic disassembly head, and realize “torque closed-loop control” based on force control data. For example, when disassembling irregular bolts on an automobile chassis, the wrench adjusts the torque in real time according to force control feedback to ensure complete bolt disassembly.

Intelligent Path Planning Algorithm: The “Smart Brain”

The system has a built-in AI path planning algorithm, which can automatically generate the optimal disassembly/grasping path based on the 3D part model scanned by 3D vision:

Obstacle Avoidance Planning: If there are other components around the part (such as oil pipes on the engine block), the algorithm bypasses obstacles and plans a path of “first lift, then translate” to avoid collisions.

Sequence Optimization: When handling irregular parts with multiple connectors (such as machine tool spindle boxes), the algorithm determines the sequence of “disassembling edge bolts first, then center bolts” based on the force relationship of the connectors, preventing part deformation due to uneven force.

Adaptive Adjustment: If the part position shifts during handling (such as slight sliding during grasping), the algorithm dynamically corrects the path using real-time visual data without manual intervention.

Scene Implementation: Penetration Across Industries from “Dismantling and Recycling” to “High-End Manufacturing”

With its core advantage of “flexible handling,” the Irregular Metal Handling Robot System has been implemented in multiple industries, solving pain points that traditional methods struggle to overcome:

- Automobile Dismantling and Recycling: Turning “Waste Parts” into “Reusable Resources”

In the scenario of new energy vehicle battery pack dismantling, battery casings are mostly irregular aluminum alloy structures, and bolts often adhere due to electrolyte corrosion. After a car recycling enterprise introduced this system, 3D vision can identify the deformed areas of the casing, and the force-controlled disassembly head can accurately control torque. As a result, the complete bolt disassembly rate increased from 60% (manual handling) to 95%, the casing recovery rate rose to 80%, and the efficiency of a single dismantling line tripled.

- Mechanical Equipment Maintenance: Reducing “Downtime Losses”

In the maintenance workshop of a heavy machine tool manufacturer, manual disassembly of worn eccentric gears used to take an average of 4 hours, causing machine downtime losses of over 20,000 yuan per day. After introducing the system, the robot uses 3D vision to locate the fitting gap between the gear and the shaft, and with the help of hydraulic disassembly tools, shortens the disassembly time to 1 hour. Additionally, the accuracy qualification rate of gears for secondary use increased from 70% to 98%.

- Aerospace Manufacturing: Ensuring “High-Precision Requirements”

In the installation scenario of curved connectors on aircraft fuselages, the connectors are irregular titanium alloy structures. Manual installation often leads to fitting deviation due to uneven force. The system controls the installation force through force control feedback, limiting the gap between the connector and the fuselage to within 0.1mm—far exceeding the 0.5mm standard of manual installation—while doubling the installation efficiency.

- Ship and Ocean Engineering: Solving “Heavy-Duty Operation Safety Issues”

Irregular steel components on ship decks often weigh over 100kg. Traditional manual handling with cranes easily leads to falling risks due to center-of-gravity deviation. After a shipyard introduced the system with a mobile base, the robot uses 3D vision to locate the component’s center of gravity and cooperates with a magnetic gripper to achieve stable grasping. The safety accident rate dropped to zero, and the handling time per component was shortened from 2 hours to 40 minutes.

Future Trends: From “Handling” to “Prediction,” the System Will Become More “Intelligent”

With the advancement of industrial intelligence, the development direction of the Irregular Metal Handling Robot System is shifting from “passive handling” to “active prediction”:

Digital Twin Simulation: In the future, the system can be connected to a production line digital twin platform. Before actual handling, it simulates the disassembly path of different irregular parts through virtual simulation, optimizes parameters in advance, and reduces on-site debugging time.

AI Fault Prediction: Based on a large amount of handling data, AI algorithms can predict the vulnerable parts of components (such as common fracture positions of certain irregular bolts) and adjust disassembly strategies in advance to further reduce the scrap rate.

Deepened Human-Robot Collaboration: For ultra-complex irregular part handling scenarios, the system can realize a “robot-led + human-assisted” model—the robot completes repetitive operations, while humans only intervene in decision-making at key nodes, balancing efficiency and flexibility.

Conclusion: More Than an “Efficiency Tool,” It Is a “Driver” of Industrial Flexibility

The value of the Irregular Metal Handling Robot System goes far beyond solving the handling problems of a certain type of part—it epitomizes the transformation of industrial manufacturing from “standardization and rigidity” to “customization and flexibility.” As more industries face “multi-variety, small-batch” production demands, and “irregularity” and “non-standardization” become the norm in manufacturing, solutions centered on “perception + adaptation” will become the “infrastructure” supporting smart manufacturing.

From the handling of waste parts in automobile dismantling plants to high-precision manufacturing in aerospace, this breakthrough of the “flexible hand” over “rigid pain points” is redefining the efficiency and safety boundaries of industrial handling—and this is the core significance of robotic technology truly integrating into the industry.